News, Consulting, Solutions

Types Of Robotic Arms And Their Uses

The robotic arm is a significant piece of the robotic machinery industry. The different types of robotic arms tend to fascinate the audience with their speed and strength. However, the usage and application of the same remain a mystery to many. This article will broadly speak about the different robot arm types and their industrial applications to provide you with a better understanding of efficient decision-making. So, keep reading.

What is a Robotic Arm?

A robotic arm is an industrial equipment used to carry out repetitive tasks through a programmed motor. A robotic arm is primarily made up of a set of joints that allow the arm to access different locations in the space around it.

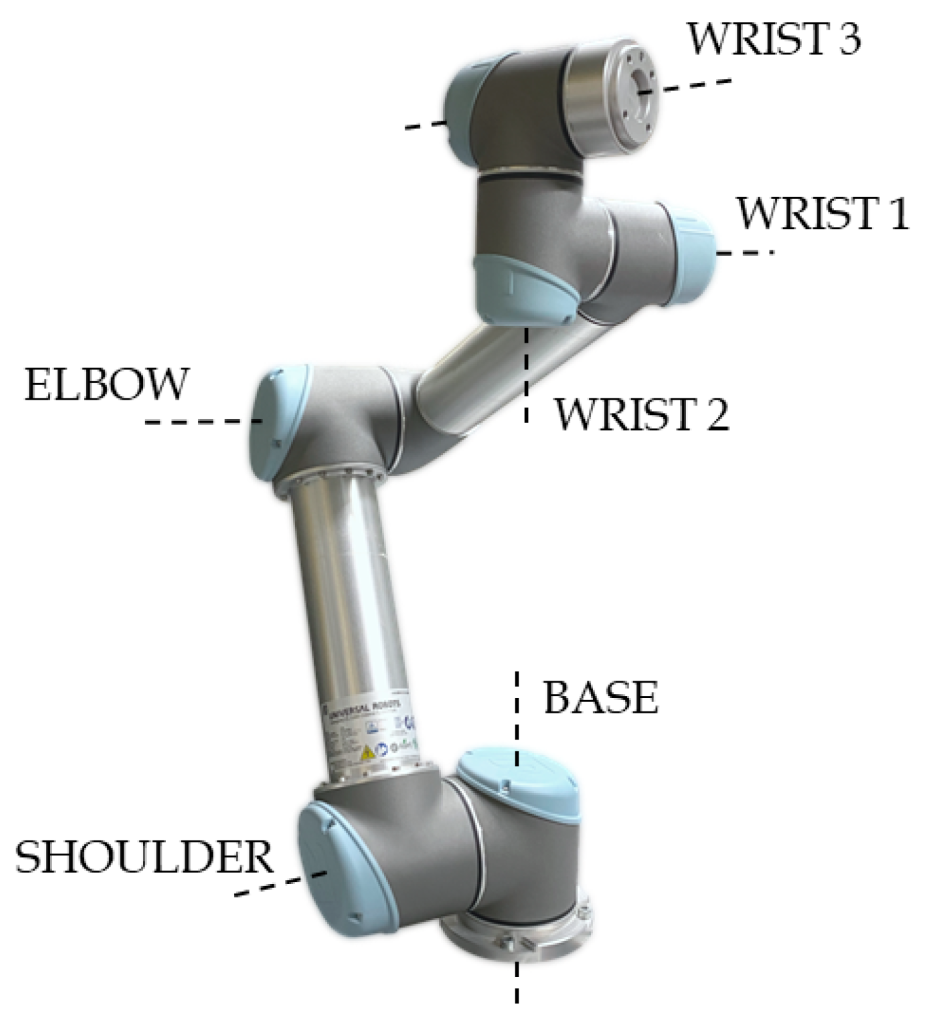

Typically, a robotic arm will have joints, actuators, and manipulators as some of its main components. The robotic arm is designed to replicate the motion of an actual human arm to the greatest extent possible. A robotic hand can be a standalone equipment used for individual tasks or can also be used as part of an extensive and more comprehensive machine. Many robotic arms that are used in different industries around the world are mounted on benchtops and can even be modular. Other robotic arms are portable and can be programmed to do a wide variety of tasks.

An essential requirement for the operation of robotic arms is programming. Modern robotic hands are created to perform multiple sets of tasks. They are built to be versatile and carry out different tasks based on the input given by the programmer.

Among the major concepts associated with robotic arms, a feature that stands out is the ‘degrees of freedom’. Degrees of freedom represent the number of dimensions each joint of a robotic arm can rotate and translate. The degrees of freedom of the joints of a robotic arm are determining factors for its flexibility and versatility. They determine the fraction of the surrounding volume that the robotic arm will be able to access and the types of tasks it will carry out.

| Learn more: Industrial Robotic Arms – Explained: Components, Operation, Types, Advantages, and Selection |

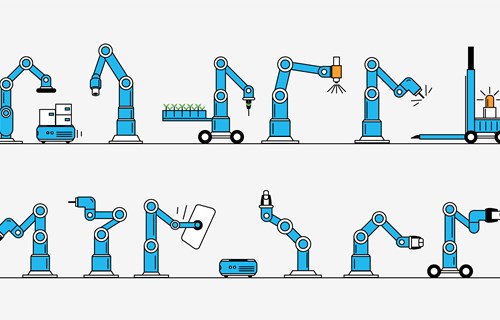

A collection of robotic devices is collectively referred to as “robotic arms.” The uses of these several robot types frequently overlap. However, each kind has unique features that often allow it to be more effective than other robotic arms for particular jobs. Various robotic arm types include:

- Articulated arm

- Six-axis arm

- Collaborative robot arm

- SCARA arm

- Cartesian arm

- Cylindrical arm

- Spherical/Polar arm

- Parallel/Delta arm

- Anthropomorphic arm

- Dual-arm

Types Of Robotic Arms And Their Uses

Types of robots in industrial use can be classified based on their technology, axis configurations, the tasks that they need to perform, payload factor, speed, and the needed range of motion. Constant advancements in robotic technology have reduced the cost and the size of robots, allowing them to execute tasks in smaller-scale applications while reducing their footprint.

An important basis of classification that we need to understand is the number of axes. These determine the degree of freedom that the robot can work in. For example, if a robot can work across the X, Y, and Z planes, it is said to have a degree of freedom of three. The higher the degrees of freedom, the more the functionality of the robot.

The following are the types of robots used for various industrial applications:

Articulated Robot Arm

An articulated robot arm resembles the human arm and allows mechanical movement and configuration. It is one of the most common types of robotic arms for industrial automation. It features a single mechanical arm attached to a base with a twisting joint.

Six-axis robots are the most common type of articulating robot, and they generally feature four to six axes, allowing for a wider range of motion. They can automate many different robotic applications, including arc welding, spot welding, painting, assembly, material removal, material handling, palletizing, and many more.

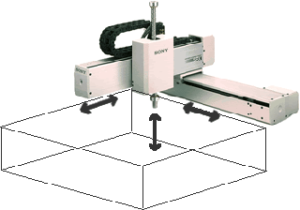

Cartesian/Gantry Robot Arm

Cartesian robots are the most commonly used industrial and commercials robots. These robots allow motion along three orthogonal axes – X, Y, and Z, and these motions are coordinated using a common motion controller.

A Cartesian robot uses only one linear actuator for each of the axes. These robots can only move in straight lines and are incapable of rotating.

Cartesian robots are mainly used in computer numerical control machines (CNCs), milling and drawing machines.

There are plenty of reasons why Cartesian robots are losing their popularity. They require a large volume to operate economically and are quite rigid in their deployment. The assembly requirements of Cartesian robots are complex. They also require an ample and confined floor space to operate.

Cylindrical Robot Arm

Cylindrical robots are quite similar to Cartesian robots, except that they operate within a cylindrical work envelope. Cylindrical robots have one angular movement and two linear movements. The cylindrical robot has a rotary joint along the joint axis for circular motion and a prismatic joint for linear motion. It is chosen for its economical use of space and the ability to reach small openings in cylindrical objects.

Cylindrical robots are relatively inexpensive, flexible, compact in size, and can work well in conditions unsuitable to humans. They are typically used to simulate human activities like assembly operations, spot welding, handling heavy materials, handling die casting machines, and handling machine tools. They are simple to use and install and are generally available as complete solutions with minimal assembly. Cylindrical robots have one significant drawback – they cannot rotate a full 360 degrees due to mechanical design limitations.

Delta Robot Arm

Also known as Parallel Link Robots, Delta robots are very different from the other types of robots mentioned above. A Delta robot uses three or four lightweight arms, which are connected via a ball-joint to a central hub. This gives it the appearance of a spider. The arms are jointed in the middle, bending inwards. They are all connected to a tooling plate, to which the end-effector is attached. Each arm is connected to a motor situated in the hub, creating coordinated movements for the arms, pushing the elbows inwards or outwards, while the hub remains parallel to the work surface.

Delta robots have a limited work envelope but can achieve high speed and acceleration in the assembly line. With technical improvements in motion control, vision guidance and conveyor tracking, delta robots are gaining usage in a variety of industries like FMCG, electronic components manufacturing, solar energy cells manufacturing, food, pharmaceuticals packaging, and medical devices manufacturing.

The main drawbacks of Delta robots are the high cost, need for extensive training for operation, and the possibility of the payload slipping due to high-speed motion.

Polar or Spherical Robot Arm

Polar robots, also known as spherical robots, feature a base coupled to an arm with two rotational joints and one linear joint. The robot’s axes combine to create a polar coordinate, enabling it to have a spherical work envelope. One of the first industrial robot categories to ever be created is the Polar Robot. Die casting, injection moulding, welding, and material handling are popular uses for polar robots.

SCARA Robot Arm

SCARA stands for Selective Compliance Articulated Robot Arm. SCARAs are the fastest of all industrial robots. They come equipped with linear X, Y, and Z axes along with the rotary motion of cylindrical robots. SCARAs have four degrees of freedom. They have a cylindrical work envelope with variations in the diameter and depth of the cylinder.

The arm in the SCARA is selectively compliant in the X-Y axis, but rigid in the Z-axis, making SCARAs ideal for fast, repeatable, and point-to-point movements. SCARA joints are all capable of rotation and can be thoroughly sealed and safeguarded, which is very important before deployment in dusty or corrosive environments, or for underwater applications.

SCARAs are ideal for modern assembly work, where fast movement with light payloads is required. Some of the tasks that SCARAs are particularly good at are Pick & Place, Laser Engraving, Soldering, and 3D Printing. SCARAs can work in high-speed assembly and are faster than all other robot types except the Delta class of robots. The main disadvantages of using SCARAs is that they are limited in movement, are higher priced, and have a large work envelope with a portion that they cannot reach.

Six-Axis Robots

Six-Axis Traditional Robots

As the name suggests, 6-axis robots can move in 6 planes, meaning that they have six degrees of freedom. Along with the regular X, Y, and Z planes, these robots also allow pitch, yaw, and roll movements. Their programming is more complicated compared to other industrial robots. 6-axis robots have an unmatched ability to make movements where the other robots cannot reach. This superior ability for movement allows these robots to mimic a human arm as a whole. They are widely used in the automotive and aerospace industry, where they can be used to weld, palletize, drill, screw, paint and apply adhesives with ease.

In comparison to the above robots, 6-axis robots have mobility, are easier to move or mount, and have a wide vertical and horizontal reach. 6-axis robots cost more since they usually have proprietary controllers for executing complicated tasks and require more programming for making complex movements. Additionally, traditional six-axis robots require a large amount of space for cages and safety scanners, as they have the potential to injure humans who cross the robot’s path of movement. This often makes them difficult to deploy for manufacturers who do not have a large amount of space on the factory floor.

Collaborative Robot/Cobot

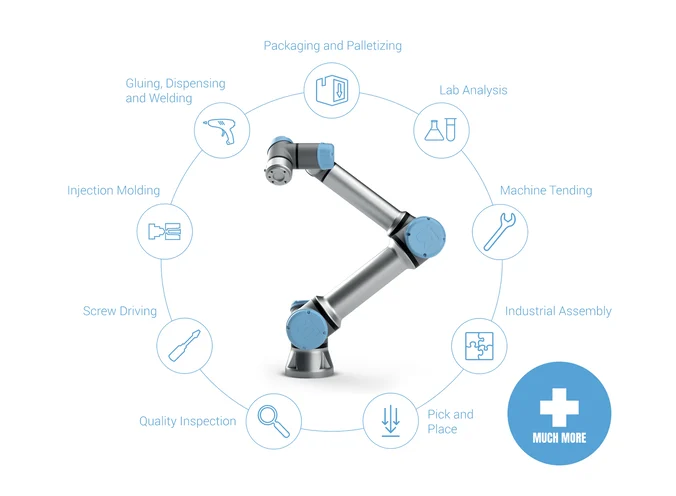

The increased sophistication of the supply chain, more intelligent control systems, AI and ML-based programming, integration with Industry 4.0 ready assembly lines, and automation of the entire production cycle has led to the increased use of collaborative robots, or cobots.

Unlike their traditional six-axis robot predecessors, cobots are built on the concept of Human Robot Collaboration, and enable safe physical interaction with humans in a shared workspace. This is thanks to their advanced safety features, primarily a protective stop that is activated when a person comes in contact with a cobot to ensure there is no injury. Cobots are small, and take up lesser space, especially because they usually don’t need cages because of their safety features.

In fact, the UR3 from Universal Robots can even easily be mounted on a table because of its compact size. The programming is also simple, with setup for a basic cobot application often taking less than a single day. All this makes them the automation solution of choice for an increasing number of manufacturers. Furthermore, Human Robot Collaboration is a key tenet and lever of Industry 4.0 and thus, cobots enabling large and small manufacturers alike to take a step in the direction of the latest industrial revolution.

Cobots help humans by handling highly repetitive, difficult, painful and dangerous tasks, increasing productivity and efficiency of the manufacturing process. This frees up the time of human operators to concentrate on the most qualified tasks with the highest added value. In fact, workers are often taught to handle the cobot and upskilled to handle tasks that require human ingenuity, thereby eliminating the mental and physical stress they may have been facing before the introduction of cobots.

Their flexibility and versatility of collaborative robots means that they are used in an array of industries for a multitude of applications, ranging from machine tending and quality inspection to packaging and palletizing.

| Learn more: What is a 6-Axis Robot? Structure, Operating Principles, and Applications |

Should You Choose a 6-Axis or 3-Axis Robot?

A 3-axis robot follows a standard X-Y-Z definition of three-dimensional space. These robots can reach forward and back, from side to side, and up and down. In contrast, a 6-axis robot has an articulated arm that allows for movement that is more similar to that of a human arm. It can rotate, bend, and move in an arc. That maneuverability means these 6-axis robots can grip objects at different angles and can rotate or tilt parts, making them ideal for more sophisticated pick-and-place applications. It typically also makes them more expensive.

For small and mid-sized manufacturers who are exploring robotics, the decision on 3-axis or 6-axis movement typically comes down to processing requirements and price. For simple pick-and-place requirements such as inserting and removing parts from a mold, a 3-axis robot may be all you need. But a robot is a long-term investment that should meet your requirements today and for years to come.

The simple process that you’re considering automating now can easily become more complex over time. You may also find that your initial foray into robotics inspires many new applications for automation, and those may require more sophisticated movement. Fortunately, the decision doesn’t have to be complicated if you can get the advantages of a flexible, long-life 6-axis robot for the price of a 3-axis robot.

How to Get a 6-Axis Robot for the Price of a 3-Axis

With Universal Robots, you don’t have to compromise between cost and performance. As a leading manufacturer of collaborative robots, we offer competitively priced 6-axis robots that provide exceptional flexibility in production. Easy to program, safe to work alongside humans, and suitable for various applications, UR robots help small and medium-sized businesses adopt automation efficiently without excessive costs.

Servo Dynamics: Official Distributor of Universal Robots in Vietnam

Servo Dynamics is proud to be the official distributor of Universal Robots in Vietnam. We are committed to delivering high-quality collaborative robot solutions, along with expert consultation, installation, and dedicated technical support, helping customers maximize the potential of Universal Robots cobots.

Conclusion

We hope this guide has provided valuable insights into the different types of robotic arms available on the market. Understanding these technologies can significantly impact your organization by improving efficiency and adaptability. Every industrial company needs tools that enhance worker productivity, adapt to evolving demands, and remain cost-effective. Collaborative robots (cobots) check all these boxes, offering a powerful solution to automate processes and modernize operations. Our team is always ready to help you maximize the potential of your robotic arms. Contact our specialists today to explore the best automation solutions for your business.

Source: www.universal-robots.com

Tiếng Việt

Tiếng Việt