Consulting, Industrial Automation

How Does a Robotic Arm Work? Detailed Structure & Operating Principles

Have you ever been amazed by the precision, speed, and continuous operation of the mechanical arms in modern manufacturing plants? That is the Robotic Arm—the backbone of the industrial automation revolution. Designed to take over heavy, dangerous, and repetitive tasks, the robotic arm is a key solution for boosting productivity, ensuring quality, and reducing operational costs.

In this in-depth article, we will explore the detailed operation of an industrial robotic arm, covering everything from its complex mechanical structure and operating principles based on kinematic models, to the various control methods and cutting-edge applications.

What is a Robotic Arm?

Concept of a Robotic Arm

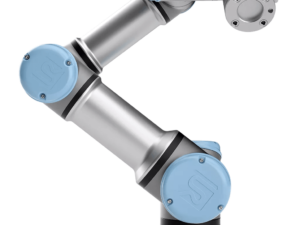

A Robotic Arm is a programmable mechanical linkage system that simulates the function and flexibility of a human arm to perform a variety of tasks within a workspace.

Essentially, it is a series of mechanical segments connected by joints. Each joint is controlled by an actuator—often an electric servo motor or a hydraulic/pneumatic system—allowing it to move in a specific way. The greater the number of joints, the higher the mobility and complexity of the tasks the robot can perform.

The Role of Robotic Arms in Automation

The role of the Robotic Arm in automation is indispensable, including:

- Increasing Productivity and Speed: Robots work continuously 24/7 at high speeds and with absolute repeatability.

- Ensuring Consistent Quality: Performing work with higher precision and consistency than human operators.

- Improving Labor Safety: Taking on hazardous tasks (such as welding, toxic paint spraying, or working in high-temperature environments).

- Optimizing Costs: Minimizing errors, material waste, and labor costs in the long run.

Current Popular Types of Robotic Arms

Robotic arms are primarily classified based on their drive mechanism:

- Industrial Robotic Arm: The general term for robots used in manufacturing.

- Hydraulic Robotic Arm: Uses compressed fluid to transmit power. Powerful, suitable for heavy loads and harsh environments.

- Pneumatic Robotic Arm: Uses compressed air. Simple, fast, often used for basic Pick & Place tasks.

- Electric – Servo Robotic Arm: Uses electric servo motors. This is the most common type in modern manufacturing due to its extremely high precision and flexibility, including Collaborative Robots (Cobots).

Structure of a Robotic Arm

A complete robotic arm is composed of the following main components working in harmony:

Base and Main Column

This is the foundational part, anchoring the robotic arm to the factory floor or workbench. It ensures stability and bears the load for the entire structure during movement.

Joint and Degrees of Freedom (DOF)

- Joint: The connection points between mechanical segments, allowing relative motion. Joints can be rotary or prismatic (linear).

- Degrees of Freedom (DOF): Each joint provides one degree of freedom. The number of DOFs (typically 3 to 6) determines the ability to position (X, Y, Z coordinates) and orient (rotation around X, Y, Z axes) the end-effector in 3D space.

Wrist and End-effector

- Wrist: Usually comprises the last 2-3 joints (Roll, Pitch, Yaw) to provide dexterity, helping to precisely orient the tool.

- End-effector (End-of-Arm Tooling – EOAT): The tool attached to the end of the arm, responsible for executing the actual task, such as a gripper, welding torch, paint sprayer, grinder, or surgical instrument.

Actuator (Servo, Motor, Hydraulic)

The Actuator is the source that provides power and motion to the joints.

- Electric Servo Motor: The most common, providing extremely precise control over position and speed.

- Hydraulic/Pneumatic Systems: Used when high force or high speed is required for simple tasks.

Position – Force – Angle Sensors

Sensors provide continuous feedback on the robot’s current state:

- Encoder/Resolver: Measures the joint’s rotation angle to determine precise position.

- Force/Torque Sensor: Mounted on the wrist or end-effector to measure the force interacting with the external environment, crucial for Cobots.

Central Controller (Controller/PLC)

The Controller is the “brain” of the system, performing the following functions:

- Stores and executes the program.

- Calculates Kinematics to determine the movement trajectory.

- Receives data from sensors.

- Controls the current/pressure delivered to the actuators.

Operating Principles of the Robotic Arm

The operating principle of a robotic arm is based on the combination of a mathematical model (kinematics) and a closed-loop control cycle.

Kinematic Model of the Robotic Arm

Kinematics is the mathematical foundation that allows the robot controller to determine position and motion.

- Forward Kinematics (FK):

- Purpose: Calculates the position and orientation (X, Y, Z, Roll, Pitch, Yaw) of the end-effector in the workspace, given the angles of all joints.

- Application: Used to check for collisions and confirm the achieved position.

- Inverse Kinematics (IK):

- Purpose: Calculates the precise rotation angles of ALL joints required to move the end-effector to a defined target position and orientation (X, Y, Z, R, P, Y).

- Application: This is the core calculation the robot uses to move from point A to point B based on a programmed command.

Operational Cycle of a Robotic Arm

The operation of an industrial robotic arm follows a repetitive cycle:

- Receive Control Command: The controller receives a command from the program (e.g., “Move to coordinates X=500, Y=200, Z=100”).

- Calculate Path (IK): The controller performs Inverse Kinematics (IK) to convert spatial coordinates into corresponding joint angles. It then calculates the optimal and safe trajectory.

- Control Motor/Actuator: The controller sends electrical signals (or pressure) to the motors/actuators, commanding them to rotate/slide to the calculated new joint angles.

- Sensor Feedback: Sensors (encoders) continuously send actual rotation angle data back to the controller. The controller uses this data to adjust and compensate for errors (closed-loop control), ensuring the achieved position is as accurate as possible.

Coordination of Joints for Precise Motion

Complex motions like welding a curve or precise assembly require the simultaneous coordination of multiple joints. The controller performs “multi-axis control,” ensuring that all joints start and stop at the same time, keeping the end-effector moving along the predefined trajectory with smooth velocity.

Illustrative Example: How a 6-Axis Robot Works

A 6-Degrees-of-Freedom (6-axis) robotic arm can position and orient the end-effector in virtually any way in space, similar to a human arm:

- 3 Primary Axes (Position): Control the X, Y, Z position of the wrist (Shoulder, Elbow, Horizontal Wrist joint).

- 3 Wrist Axes (Orientation): Control rotation around 3 axes (Pitch, Roll, Yaw), allowing the tool to approach objects from any angle.

How Does a Hydraulic Robotic Arm Work?

Structure of a Hydraulic Robotic Arm

Unlike electric servo robots, the hydraulic robotic arm is built to handle massive loads. The main structure includes:

- Hydraulic Pump: Generates high pressure for the fluid (oil).

- Cylinder and Piston: Converts fluid pressure into linear force (pushing/pulling motion).

- Control Valve: Regulates the flow and direction of the fluid to the cylinders, thereby controlling the joint movement.

- Reservoir: Stores the hydraulic fluid.

Principle of Force Transmission by Cylinder

The core principle is based on Pascal’s Law: Pressure applied to a non-compressible fluid is transmitted equally throughout.

- The pump generates high oil pressure.

- The control valve directs the high-pressure oil into the cylinder chamber.

- This pressure acts on the piston, creating an enormous pushing/pulling force to move the robot joint. The output force is directly proportional to the pressure and the piston area.

Why Are Hydraulic Models Used in Schools?

Self-made hydraulic robotic arm models (often using syringes or pumps) are popular in education because:

- Easy Visualization: Students can visually observe how fluid transmits force.

- Low Cost and Safety: Simple models do not use high voltage or complex motors.

- Mechanical Practice: Helps understand basic concepts of levers, pressure, and actuation mechanisms.

Pros and Cons of Hydraulic Systems

| Pros | Cons |

|---|---|

| Generates extremely high force and torque (suitable for heavy loads). | Lower positioning accuracy and repeatability than servo robots. |

| High durability, operates well in harsh environments. | Prone to oil leaks, requires more complex maintenance. |

| High power-to-weight ratio. | Response and operation speed are often slower. |

Robotic Arm Control Systems

The control system dictates how the operator interacts with and programs the robot.

Control via PLC

The PLC (Programmable Logic Controller) is the standard controller in industrial automation environments. PLC control offers high reliability, good noise immunity, and easy integration with other peripherals (conveyors, CNC machines). It is typically used for repetitive tasks with fixed cycles.

Control via Arduino / ESP32

Microcontrollers like Arduino or ESP32 are widely used in educational projects, research, or small models. They provide an open-source, simple, and low-cost programming platform to control servo motors, suitable for testing basic algorithms.

Control via Robot Simulation Software (RoboDK, ABB RobotStudio…)

Offline Programming (OLP) via simulation software (like RoboDK, ABB RobotStudio, KUKA Sim) allows users to create and test robot programs on a computer without disrupting the actual production line. This shortens setup time and optimizes the robot’s path.

Control via Machine Vision

Machine Vision provides “eyes” for the robot. Cameras are used to:

- Identify the position and orientation of objects (random Pick & Place).

- Inspect product quality (detect defects, dimensions).

- Guide the robot to the precise welding, assembly, or inspection point.

Robotic Arm Control via Gesture / AI

This is an advanced control trend, enabling:

- Gesture Control: The robot mimics the operator’s movements via external devices (data gloves, position sensors).

- AI (Artificial Intelligence): The robot learns from data and the environment to make optimal decisions, such as automatically planning paths to avoid obstacles or self-adjusting welding speed according to material surface.

Types of Robotic Arms by Degrees of Freedom (DOF/Axes)

1–2 DOF Robotic Arms

Perform very simple movements:

- 1 DOF: Linear push/pull or fixed angle rotation (e.g., simple lever).

- 2 DOF: Movement on a plane (X, Y) or grasping and rotating.

3–4 DOF Robotic Arms

Sufficient for planar or simple spatial tasks:

- 3 DOF: X, Y, Z positioning (often simple Cartesian robots).

- 4 DOF: Most commonly the SCARA robot (3 position DOFs and 1 wrist rotation DOF), ideal for high-speed assembly and packaging.

5–6 DOF Robotic Arms

The most common types in industry:

- 5 DOF: Capable of 3D positioning and good orientation, but limited in some rotational angles.

- 6 DOF: Provides maximum flexibility (3 position + 3 orientation), suitable for most complex applications like arc welding, paint spraying, and machine tending.

7 DOF Robotic Arms (Advanced)

Robots with redundant degrees of freedom. This allows the robot to have multiple joint configurations to reach the same end-point. Benefits:

- Better Obstacle Avoidance: Can reach a target while bending to avoid obstacles.

- Working in Confined Spaces: Very useful in surgery or cramped assembly environments.

Comparison: When to Use Which Type?

| Number of DOF | Key Feature | Suitable Application |

|---|---|---|

| 1-2 | Simple linear/rotary motion. | Basic sorting, button pressing. |

| 3-4 | High speed, planar work (SCARA). | Electronic component assembly, simple Pick & Place. |

| 5-6 | High flexibility, full 3D space coverage. | Welding, painting, machine tending, complex palletizing. |

| 7+ | Redundant degrees of freedom. | Surgery, detailed inspection, environments with obstacles. |

Practical Applications of Robotic Arms

The Robotic Arm has moved beyond the automotive factory to be present in almost every sector.

In Industrial Manufacturing

- Pick & Place: High-speed robots moving items from one location to another (using Delta, SCARA robots).

- Robot Welding: Arc welding, automotive spot welding with consistent speed and quality, unaffected by temperature.

- Paint Spraying: Robots move the spray nozzle along a high-precision trajectory, ensuring uniform coating thickness and quality, while protecting worker health.

- Palletizing: Automatic stacking of products or cartons onto pallets, minimizing the risk of injury.

- Assembly: Assembling small components (like circuit boards, phones) with micron-level precision.

In Medicine and Surgery

Surgical robots (e.g., the Da Vinci system) help surgeons perform minimally invasive procedures with much higher precision and stability than the human hand.

In Service: Coffee Brewing, Cooking, Massage

Collaborative Robots (Cobots) are gradually entering the service industry, performing repetitive tasks like brewing beverages, baking, or massaging with high safety standards for customer interaction.

Special Applications: Filming Robots, Image Processing Robots

In the film and photography industry, high-speed robotic arms are used to control cameras, creating precise, repeatable, and ultra-fast camera movements that are impossible to achieve manually.

Popular Robotic Arm Brands in the Market

The industrial robot market is dominated by “Giants” along with the strong rise of collaborative robots.

UR Series (UR3/UR5/UR10)

- Universal Robots (UR): A pioneer in the Collaborative Robot (Cobot) field. Known for their safety features, ease of programming, and rapid deployment. The UR3e, UR5e, UR10e series are the gold standard for collaborative applications.

ABB

- One of the world’s largest robot manufacturers. Offers a wide range of products, from small to heavy-payload robots, renowned for reliability and performance.

KUKA

- A German brand, known for its characteristic orange color. Specializes in high-payload and high-precision robots, particularly strong in the automotive industry.

Yaskawa

- A Japanese industrial giant, with the Motoman robot line diverse in type, from welding robots and material handling robots to assembly robots.

Fanuc

- A Japanese brand, famous for its yellow color. Fanuc robots are extremely durable, operate well in harsh environments, and hold a large market share in welding and heavy material handling.

Mitsubishi, Epson, Kawasaki

- Other Japanese brands that offer specialized robot lines, especially SCARA robots (Epson, Mitsubishi) for high-speed applications and heavy-payload robots (Kawasaki).

Comparison: Hydraulic – Pneumatic – Electric Servo Robotic Arms

| Criteria | Hydraulic | Pneumatic | Electric Servo (Most Common) |

|---|---|---|---|

| Precision | Lowest (due to fluid compressibility/leaks). | Low (compressed air is hard to control). | Highest (Position controlled by encoders). |

| Speed | Slower, stable for heavy loads. | Very fast (for simple tasks). | Fast and flexible (optimized trajectory). |

| Cost | High (complex pump, valve systems). | Low (simple equipment). | Medium to high (depends on load/precision). |

| Application Environment | Heavy loads, high temperature, dirty environments. | Light tasks, high speed, non-absolute precision needed. | Most applications, clean environments, high precision required. |

The Importance of Joints in Robotic Arms

Because robotic arms are inspired by the human arm, you’ll typically see them with multiple joints, allowing for free and flexible movement. A “joint” is simply any movable part of the robotic arm.

Each joint operates independently while also working seamlessly with the others for maximum performance. This is why a robotic arm can move up and down while rotating simultaneously. In short, a robotic arm cannot function without joints, and an industrial robotic arm must have at least two joints.

The more joints a robotic arm has, the greater its maneuverability. These joints – often called “axes” – are crucial in defining how a robotic arm will function. Joints provide freedom of movement, making a robot incredibly versatile.

Joints also offer a structure that simplifies maintenance and repair. If a failure occurs, it’s easy to pinpoint the problem to a specific joint rather than guessing.

Flexible joints allow robotic arms to twist, turn, and move up and down with ease.

Servo Dynamics Engineering: Authorized Distributor of Universal Robots in Vietnam

Are you looking for an optimal collaborative robotic arm solution for your business in Vietnam?

Servo Dynamics Engineering (SDE) is proud to be the authorized distributor of Universal Robots—the world’s leading collaborative robot (cobot) brand. With extensive experience and expertise in automation, we are committed to providing the most advanced robotic solutions, helping businesses optimize production processes, enhance efficiency, and minimize operating costs.

Our team of engineers is ready to provide expert consultation, installation, and dedicated technical support, ensuring your robot system operates smoothly, efficiently, and safely, meeting all stringent customer requirements.

Discover Universal Robots Products

Learn more

Tiếng Việt

Tiếng Việt