Consulting, News

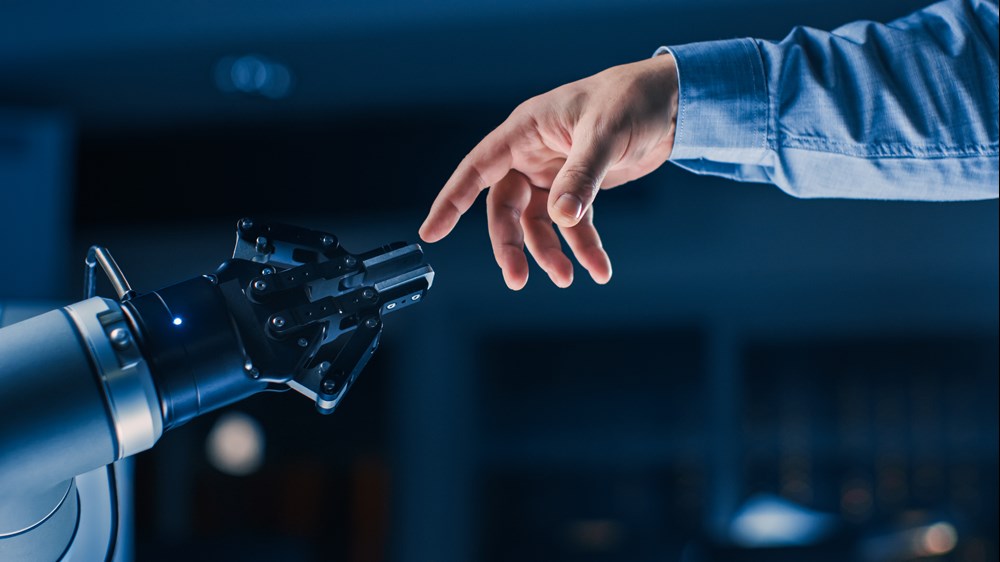

Collaborative Robots and Humans: When Robots “Shake Hands” with Humans

The relationship between humans and robots is becoming closer than ever. Rather than being adversaries, robots are gradually becoming valuable “colleagues” that assist humans in both work and life. The concept of collaborative robots (cobots) marks a new milestone in this relationship. Cobots are designed to interact safely and effectively with humans in shared workspaces. They can work alongside humans, help with difficult tasks, or even replace humans in certain steps of a process.

This article provides an overview of human-cobot collaboration, including aspects of safety, roles, capabilities, and potential applications of cobots.

The Necessity of Human-Robot Collaboration

The benefits of traditional industrial robots are undeniable, but there are still limitations that only robots capable of truly collaborating safely with humans can solve. Here are the reasons why collaboration between robots and humans is necessary.

Business Disruptions and Challenges

The COVID-19 pandemic dealt a heavy blow to businesses by disrupting supply chains and production activities for an extended period. Beyond the impact of the pandemic, market demands are constantly changing, forcing manufacturers to struggle to find new directions. Customers increasingly require products with more customization and higher standards, leading to fierce competition in the market to meet these demands in a timely manner. All these business disruptions and challenges demand that manufacturers react quickly, adapt production processes flexibly, and optimize costs.

Challenges of Full Automation

Traditional industrial robots are often bulky and dangerous to humans, so production processes tend to be either fully automated or entirely manual. However, each option comes with its own set of challenges.

Building a fully automated factory, without any human presence, seems like an impossible task after many lessons learned. This requires significant research investment, high implementation costs, and considerable risks.

On the other hand, fully manual production may involve heavy, dangerous, and monotonous tasks that can cause injuries, affect workers’ health, and fail to optimize productivity. The best solution is to combine the strength of robots with human capabilities.

Advantages of Human-Robot Collaboration in Production

To quickly and flexibly adapt to business disruptions and solve the challenges between automated and manual production, collaboration between robots and humans is essential.

The strength, accuracy, and agility of robots can take on heavy, dangerous, and repetitive tasks, while humans can handle other, more valuable tasks, which can also contribute to their greater job satisfaction.

The Emergence of Collaborative Robots (Cobots)

To address the limitations of both traditional industrial robots and manual labor, collaborative robots (cobots) have emerged as an optimal solution. Unlike conventional industrial robots, cobots are designed to work safely alongside humans without the need for protective barriers. They are flexible, easy to program, and can quickly adapt to changes in production.

The Advantages of Human-Robot Collaboration

The combination of humans and collaborative robots (cobots) is becoming increasingly common in various industries, from manufacturing, healthcare, logistics to retail. This model not only enhances productivity but also opens up many opportunities for improvement in work processes. Here are the key advantages of human-robot collaboration:

Enhancing Productivity and Efficiency

- Optimizing Processes: Robots can handle repetitive, monotonous, and time-consuming tasks, allowing humans to focus on more complex tasks that require higher skills.

- Accelerating Production: Robots can work continuously, tirelessly, increasing production speed and reducing waiting times.

- Reducing Errors: Robots’ high accuracy helps minimize errors in production processes, improving product quality.

Improving Working Conditions

- Reducing Risks: Robots can take on dangerous and hazardous tasks, reducing risks for workers.

- Reducing Stress: Robots can help alleviate stress for workers by taking on heavy, monotonous tasks.

- Creating Comfortable Work Environments: Robots help create a more comfortable work environment, enabling workers to focus on their tasks.

Increasing Flexibility

- Easy Adaptation: Robots can be easily programmed and adjusted to perform different tasks, making businesses more flexible in their production.

- Meeting Market Demand: Robots help businesses meet market demands quickly and efficiently.

- Optimizing Resources: Robots allow businesses to optimize resources by using robots for suitable tasks and humans for tasks requiring higher skill levels.

Cost Savings

- Reducing Labor Costs: Robots can help reduce labor costs by replacing humans in simple, repetitive tasks.

- Reducing Maintenance Costs: Robots have a long lifespan and are less prone to breakdowns, which helps reduce maintenance costs.

- Optimizing Production Costs: Robots help optimize production costs by minimizing waste of materials and energy.

Creating New Opportunities

- Technology Development: The collaboration between robots and humans drives the development of robot technology and artificial intelligence.

- Creating New Jobs: The growth of robot technology creates new jobs in fields such as design, manufacturing, programming, and robot maintenance.

- Enhancing Skills: Workers have opportunities to upgrade their skills to work with robots, meeting the future demands of their roles.

Applications of Collaborative Robots

Applications of Collaborative Robots in Repetitive and Tedious Tasks

Repetitive and monotonous tasks can cause more harm than you might think. They affect workers’ mental health, making them more prone to irritability, dissatisfaction, depression, and even affecting the morale of other employees. Workers are also more likely to make mistakes and experience reduced productivity when performing tedious tasks for prolonged periods. Studies show that boring tasks are the leading cause of employee turnover, with resignation rates being twice as high compared to other factors. These issues indirectly lead to significant losses for businesses.

Collaborative robots are an excellent solution to free workers from repetitive, monotonous tasks, allowing them to focus on self-improvement and take on more valuable responsibilities.

Some of the monotonous and repetitive tasks that collaborative robots excel at include:

- Assembling components

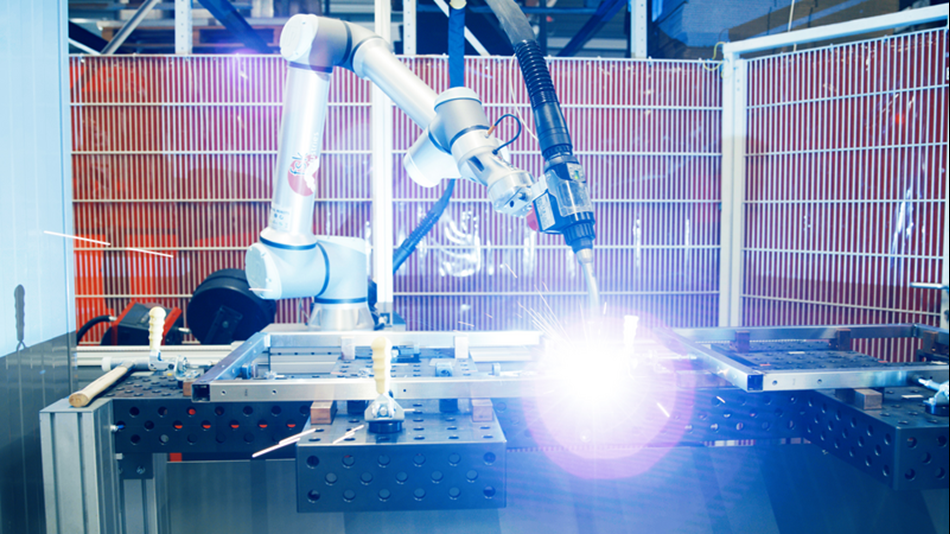

- Welding, gluing, and screwing

- Packaging goods

- Picking and placing parts

Applications of Collaborative Robots in Harsh, Dangerous, and Hazardous Tasks

Collaborative robots (cobots) are also well-suited for handling harsh, dangerous, and hazardous tasks, ensuring the health and safety of workers while simultaneously increasing efficiency. Instead of being exposed to industrial chemicals or dust, workers can enjoy greater job satisfaction by simply standing outside the danger zone and operating the robot through a user-friendly touchscreen interface.

Some of the dangerous and hazardous tasks that cobots can replace human workers in include:

- Spray painting

- Welding

- Grinding and material cutting

Applications of Collaborative Robots in Ergonomically Challenging Tasks for Humans

Musculoskeletal disorders are a common issue, especially in the manufacturing industry, and they significantly affect workers’ health and performance. According to FitForWork Europe, this is a major problem in the modern world.

In Vietnam, the concept of ergonomics is still not prioritized, and businesses often overlook the health of their workers. Musculoskeletal injuries can impact the quality of work and are one of the leading causes of absenteeism. According to FitForWork Europe, the European Union estimates losses of approximately 240 billion euros annually due to reduced productivity and absenteeism caused by musculoskeletal disorders.

Applications of Robots in Ergonomically Challenging Tasks

Proven Labor Safety in Real Manufacturing Environments

Collaborative robots (cobots) have been in use for a long time, and their safety in real-world manufacturing environments has been proven over time.

Etalex is an example of a company aiming to use robots to boost productivity and free employees from mundane tasks. However, with limited space, ensuring the robot operates safely alongside employees in the same area became a top priority. Collaborative robots were the ideal solution for this challenge as they occupy a small footprint, do not require protective barriers, and still ensure safety.

Can Cobots Replace Humans?

Have you ever wondered if cobots could fully replace humans in their jobs? Many tasks are already being replaced by cobots, from simple, repetitive tasks to more complex ones that require high skill levels. Let’s explore the tasks that cobots can replace and those they still cannot perform perfectly.

Tasks Cobots Can Replace Humans

- Repetitive, monotonous tasks: Cobots can easily replace humans in these tasks, improving productivity and reducing errors. For example, assembling products, packaging goods, and transporting items in warehouses.

- Dangerous, hazardous tasks: Cobots can work in harsh and dangerous environments where humans should not or cannot work. For example, welding in hazardous environments, handling radioactive waste, and firefighting.

- Tasks requiring high precision: Cobots can perform tasks with absolute accuracy, unaffected by human factors. For example, surgery, measurements in manufacturing, and product quality control.

Tasks Cobots Cannot Replace Humans

- Creative tasks: Cobots are still limited in creativity, critical thinking, and flexible problem-solving. For example, product design, screenwriting, and music composition.

- Tasks requiring soft skills: Cobots cannot replace humans in roles that require communication, negotiation, persuasion, and teamwork. For example, sales, customer consulting, and human resource management.

- Tasks requiring emotions and empathy: Cobots cannot replace humans in jobs requiring empathy, understanding, and care. For example, taking care of the sick, elderly, and children.

Although cobots can perform many tasks more efficiently than humans, especially physically demanding or dangerous ones, they cannot replace humans entirely. Cobots need human support in solving complex situations, being creative, and making strategic decisions. Moreover, jobs that require emotions and deep understanding of humans remain areas where robots struggle to replace humans.

Collaborative Robots in the Future

The manufacturing and automation world is developing at an astonishing pace. The demand for greater flexibility, improved safety, and cost savings is pushing collaborative robots (cobots) to the forefront.

The global market for these robots is expected to grow by over 20% annually from 2024 to 2028 and will double by 2030. A recent survey found that 84% of businesses plan to introduce or increase the use of robot automation in the next decade. We are truly entering a new era of intelligent automation.

According to an industry study by ABB in January 2023, which surveyed 1,500 large and small businesses in Europe, the US, and China.

How Cobots Will Change the Business Market in the Future

In the near future, cobots will positively transform certain industrial sectors, setting the stage for increasing competitiveness in production and logistics in the broader business market.

In similar industries and sizes, not all companies have the same competitive ability in production and logistics. These two factors are key in assessing a company’s position in any market. The smart robots developed by Universal Robots are expected to bring significant changes in the future.

How Cobots Help Handle Business Fluctuations in the Future

In the future of the business market, the advantages of cobots are not just about creating change, but also about coping with market fluctuations. The smart robots from Universal Robots have been highly regarded for providing the following values:

- Boosting productivity: This is the top reason businesses choose automation technology.

- Increasing profitability: This is the natural result of higher productivity and lower costs.

- Employee satisfaction: Reducing physical strain and improving the working environment are key advantages of robots for workers.

- Improving quality: Minimizing errors and ensuring consistent product quality are ways cobots enhance product standards.

- Enhancing flexibility: With simple programming, adjustments, or quick reassembly of parts, the robots from Universal Robots are ready for a new task.

How Cobots Will Change How Humans Work in the Future

Always improving and integrating new technology is how cobots are developed to assist humans. So, it’s time to discuss the journey of robots replacing humans in some manufacturing tasks in the future. These tasks initially affect workers directly but will gradually influence business operations.

For physically demanding tasks, replacing humans with robots will improve the labor capability of workers, increasing their productivity and career longevity. As a result, businesses will need fewer hires and training sessions.

For repetitive tasks, replacing humans with robots will eliminate boredom, which can lead to mistakes due to lack of concentration, while also reducing inconsistent product quality at businesses.

For dangerous tasks, such as those involving toxic chemicals or taking medical samples, robots are essential to fully replace humans in the future.

How Cobots Will Change How Business Owners Operate in the Future

Adopting cobots equals implementing automation, meaning business owners are ready to change their operational methods in the future. Specifically, in two key areas:

- Automating production processes: Smart robots will gradually be applied across multiple stages of the production process once workers become accustomed to working with cobots.

- Automating factory operations: Smart robots change the concept of 100% manual operation to integrated human-robot collaboration for maximum efficiency.

How Cobots Will Create Change in Developing Countries

There’s no denying that cobots play a key role in the industrial sector, especially in developing countries where this sector constitutes a significant portion of their economies. Smart robots boost productivity in industrial manufacturing, helping these countries increase their output and raise their standing on the global stage.

Cobots open up opportunities for businesses to adopt and apply technology in production. This can be seen as a solution for developing countries where manufacturing is major but technological infrastructure is still limited. Smart robots improve the working environment significantly in these regions while also boosting morale and increasing enthusiasm for tasks.

Universal Robots: Leading the Cobot Revolution

Universal Robots, the pioneer and global leader in collaborative robots, offers flexible, safe, and easy-to-use automation solutions for businesses of all sizes. Universal Robots cobots stand out with their exceptional benefits, helping companies optimize production processes and enhance their competitiveness:

- Flexibility: Easily programmable and adjustable for a wide range of tasks, from assembly, product handling, to quality testing and beyond.

- Absolute safety: Designed to work safely alongside humans in shared work environments, without complex protective measures.

- User-friendly: With an intuitive interface, minimizing training and implementation time.

- Scalability: Easily integrates with other equipment and systems, meeting all automation needs of businesses.

- Cost-efficiency: Quick return on investment, helping businesses save on operational and capital expenses.

Servo Dynamics: Official Distributor of Universal Robots in Vietnam

Servo Dynamics is proud to be the official distributor of Universal Robots in Vietnam. We are committed to providing high-quality collaborative robot solutions, along with expert consulting, installation, and technical support services, ensuring our customers can fully harness the potential of Universal Robots’ cobots.

Discover Universal Robots Products

View More

Tiếng Việt

Tiếng Việt