Industrial Automation, Solutions

5 ROBOT PREDICTIONS FOR 2025: HOW AI IS TURNING THE IMPOSSIBLE INTO REALITY

The robotics industry is standing at a critical turning point. Over the past two years, artificial intelligence (AI) has significantly reshaped our perception of technology’s potential. Once seen as a trendy buzzword, AI is now becoming a core element of how businesses operate and grow.

As we move into 2025, the focus will shift from innovation for innovation’s sake to practical implementation — real-world solutions that can be deployed immediately in manufacturing, logistics, and beyond, transforming industries on a global scale.

In robotics, AI is unlocking capabilities that were once out of reach. Robots, which were traditionally limited to repetitive tasks in controlled environments, can now understand context, make decisions, and perform complex operations independently. This evolution is redefining how industries operate, from manufacturing and logistics to healthcare, and shaping the future of work.

One of the leading voices in this space is Anders Billesø Beck, Vice President of Technology at Universal Robots — a global leader in collaborative robotics (cobots). With a mission to make automation accessible and practical, Anders bridges the gap between advanced technology and everyday business operations.

He emphasizes that robots aren’t here to replace people — they’re here to support them, making work safer, more efficient, and more creative. In this future, robots aren’t just machines on the factory floor — they’re trusted tech-enabled colleagues across every industry.

What is a Robot?

A robot is a machine designed to perform a series of actions automatically. Robots can be programmed to carry out specific tasks such as assembling components, welding, painting, or packaging.

Today, robots are widely used across sectors, including industrial manufacturing, healthcare, entertainment, and transportation. They are typically employed to handle tasks that are dangerous, repetitive, or too complex for humans.

With their precision and ability to work continuously, robots help businesses boost productivity, cut costs, and improve workplace safety. In the age of digital transformation, robots are no longer just support tools — they are key drivers of sustainable innovation and growth.

What is Robotics?

Robotics is the field of engineering and science focused on the design, construction, operation, and application of robots. It draws from multiple disciplines, including mechanical engineering, computer science, mathematics, and physics.

In simple terms, robotics involves building the full system of a robot, from hardware like robotic arms and sensors to the software that controls them. The goal of robotics is to create intelligent systems that can assist or replace humans in various environments, from industrial assembly lines to healthcare facilities.

Thanks to rapid technological advancements, robotics is becoming an integral part of modern life and smart manufacturing, helping companies improve efficiency, reduce operational costs, and maintain high safety standards.

What’s the difference between Robotics and AI?

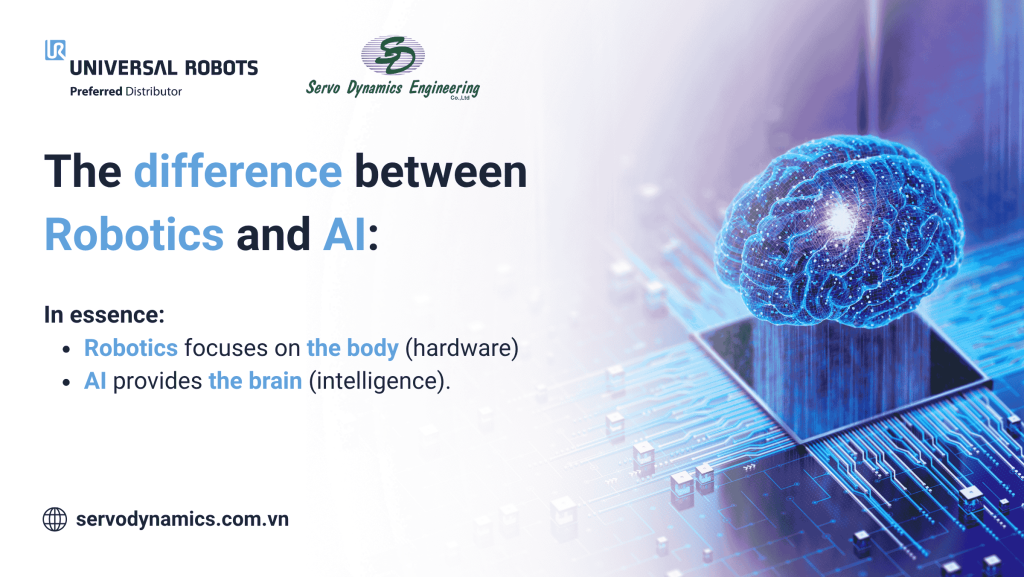

Robotics and Artificial Intelligence (AI) are closely related fields, but they serve different purposes.

Robotics is primarily concerned with building and operating physical machines (robots) that can perform specific tasks, such as assembling electronics or assisting in surgical procedures.

AI, on the other hand, is about developing intelligent systems that can mimic human thinking and behavior, such as understanding language, recognizing images, analyzing data, and making decisions using algorithms.

When AI is integrated into robots, it makes them smarter. For instance, an autonomous robot equipped with AI can interpret its surroundings and adapt its actions accordingly. However, not all robots use AI — many operate based on fixed programming without the ability to “think” or adapt.

In essence, robotics focuses on the body (hardware), while AI provides the brain (intelligence).

5 Key Robot Predictions for 2025

1. AI reaches a new level of maturity

2025 will mark a pivotal year where AI transitions from trend to practical utility. While many AI startups have emerged in recent years, this year we’ll see increased consolidation and deeper integration into real-world systems.

AI will become a seamless part of existing infrastructures — no longer marketed as standalone “AI solutions” but as essential, invisible components of broader systems. For instance, the collaborative robot (cobot) solution from Ocado doesn’t highlight AI in its branding, but it’s powered by it behind the scenes to streamline warehouse operations.

The next generation of AI won’t just exist in software — it will have physical capabilities. We’re now entering the era of physical AI: systems that understand physics, respond to unexpected events and navigate real-world environments. This deeper integration with robotics will allow machines not just to process data but to physically interact with and shape the world around them.

2. Robots move into everyday life: From baristas to chefs

For decades, robots have worked mostly behind the scenes in factories. But in 2025, they’re becoming a visible part of daily life. Humanoid robots are still years away from widespread adoption, but cobots are already gaining traction across many sectors.

In entertainment, cobots are being used to operate cameras in films, TV shows, and commercials, such as MRMC’s robotic camera systems.

In food and beverage, cobots are increasingly used to prepare coffee and meals, particularly in the U.S. and Asia. By the end of 2024, chances are you’ve already enjoyed a coffee or dish prepared with robotic assistance. Cobot solutions ensure consistency and speed during peak hours. Fast food chain Chipotle is among the pioneers of using cobots in their kitchens.

Construction is also seeing a rise in cobot use. Companies like Canvas use cobots to automate drywall finishing, helping address skilled labor shortages. Others, like Raise Robotics, are deploying cobots to install hardware on tall buildings — a task that is both dangerous and repetitive.

Building the Future: Cobots Revolutionize the Construction Industry

3. The automation boom in India

While China, Japan, and South Korea have traditionally led in robotics, India is emerging as a major player by 2025. With strong government support, including incentive programs like the Production Linked Incentive (PLI) scheme, India is ramping up investments in automation across sectors such as automotive, metals, pharmaceuticals, and food processing.

India’s automation potential is being driven by three major factors:

- A young, dynamic workforce — with a median age of 29 (compared to 45 in Germany).

- A booming tech sector, worth $115 billion in IT and business process management (BPM).

- Pro-automation policies — focused on digitization, skills development, and industrial modernization.

As part of the “Make in India” initiative, India jumped from 10th to 7th in global robot installations, with a 59% year-over-year increase. This shows how India is rapidly becoming a global hub for automation and innovation.

4. A new approach to robot safety

Safety has always been a core feature of cobots (collaborative robots). But as cobots enter more dynamic and unpredictable environments, traditional safety methods need to evolve.

Safety requirements depend on the specific use case. While cobots are built to work alongside humans, additional safety measures are still required when operating at high speeds or handling sharp tools. In factories, fences and strict safety protocols are the norm, but these don’t work well when cobots need to interact freely with humans.

The future of safety lies in adaptive technologies. Advanced sensors and AI algorithms will allow cobots to detect and respond to human movement in real-time, enhancing safety without sacrificing productivity. This shift will be key to expanding the use of cobots into new, less predictable environments.

5. Rise of standardized turnkey robot solutions

Although not a new concept, standardized turnkey solutions will become essential in 2025. These pre-configured automation packages make it easier for companies to deploy robots without the need for complex customization or long setup times.

Their biggest advantage? Simplicity. Businesses—especially small and mid-sized enterprises—can start using robots without deep technical knowledge or massive budgets.

A bold prediction: by the end of 2025, more than one-third of all cobots will be deployed through standardized turnkey solutions. With scalability, lower costs, and rapid implementation, these solutions will drive adoption across the manufacturing and logistics industries.

Explore the Applications of Robots in Modern Industry

Shaping the future of automation

There’s no doubt that 2025 is a turning point for robots. From the rise of physical AI to cobots working alongside people in everyday settings, automation is entering a new era.

Robots are not just helping businesses tackle global challenges like labor shortages and supply chain disruptions — they’re also unlocking new levels of productivity and operational excellence. With advanced technologies like AI and standardized solutions, robots are becoming more accessible and impactful than ever.

As businesses embrace innovation, they’ll discover that the true power of robots lies not in replacing people but in working with them to build a safer, smarter, and more connected future.

Discover Universal Robots Products

Learn more

Tiếng Việt

Tiếng Việt