Consulting

What is a Signal Tower Light? Classification, Applications, and Wiring Guide

In the context of the 4.0 Industrial Revolution, instant and visual communication about the operational status of machinery is vital to ensuring safety and optimizing production efficiency. The Signal Tower Light (also known as a Stack Light) serves as a non-verbal “light language,” providing clear and immediate indication of machine status, system conditions, and safety status.

This in-depth article will delve into the definition, structure, classification criteria, operating principles, and detailed technical guidance on how to wire a 3-tier signal tower and other types, helping you select and integrate this device most effectively.

What is a Signal Tower Light?

Concept of Industrial Tower Lights

A Signal Tower Light is a multi-tier visual signaling device, essential in automation systems and manufacturing environments. This device consists of vertically stacked colored LED modules, acting as an instant status indicator interface (status indicator) for equipment, processes, or work areas.

Each color on the signal tower light adheres to international standards (such as ISO and IEC) to represent a specific status:

| Color | Standard/Meaning | Typical Machine Status |

|---|---|---|

| Green | Safe, Normal Operation | Machine running, production cycle in progress. |

| Yellow/Amber | Warning, Caution | Low material, scheduled maintenance, or minor deviation. |

| Red | Danger, Critical Error | Emergency stop, machine fault, or safety hazard. |

| Blue | Notification/Support Request | Requires supervisor/maintenance staff, or machine is waiting for data. |

| White/Clear | Standby/Additional Information | Machine is in standby mode, or quality check is in progress. |

Structure of the Signal Tower Light

Modern Signal Tower Lights are designed using a Modular Design or Pre-assembled structure to optimize installation and maintenance.

Lamp Module (Multi-color LED)

The main display component, using super-bright LED technology, provides clear visibility even under strong light. The lamp module is often made from high-grade impact-resistant plastic (like Polycarbonate or ABS) for shock resistance and heat tolerance. LED lifespan meets industrial standards of 50,000 hours, reducing replacement costs.

Buzzer Module

Integrated alarm provides auditory warning, especially important in noisy production environments. The buzzer typically has adjustable sound intensity (usually 85dB to 105dB) and can emit various types of audible alerts (continuous tone, intermittent tone, or multi-frequency melodies) to differentiate emergency levels.

Pole and Base

- Poles: Used to raise the lamp module to an appropriate height, with different length options available.

- Base: The device fixing the signal tower, offering flexible mounting types: Direct Mount, Pole Mount, or Wall Mount. The base design must ensure resistance to vibration during machine operation.

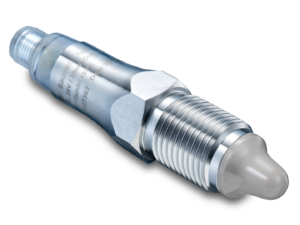

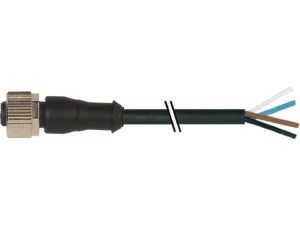

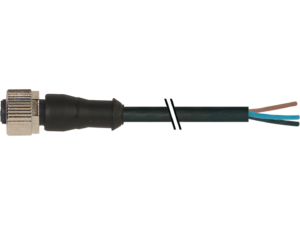

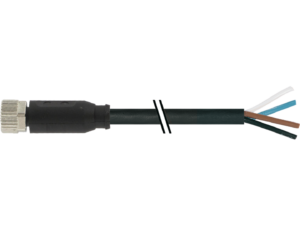

Wiring & Terminal Block

Electrical wiring and Terminal Block system to connect each lamp tier (and buzzer) to the control system. High-end models may use M12 quick connectors or network connections to transmit control signals and status data.

Operating Mechanism of the Tower Light

Operation is based on simple On/Off control from the control system:

- Signal Reception: The tower light is connected to the Digital Output of a PLC, Microcontroller, or Relay.

- Activation: When the PLC detects a status change (e.g., excessively high temperature), it activates the corresponding output, supplying voltage (e.g., 24VDC) to the Red light tier signal wire.

- Display: Current flows through the module’s control circuit, illuminating the LED. Depending on the setting, the light can be Steady or Flashing/Strobe.

In DC systems (12V/24V), attention must be paid to the PLC’s Sourcing (PNP) or Sinking (NPN) control type to ensure accurate wiring between the tower light’s Common wire and the power source (0V or +VDC).

Functions and Benefits of Signal Tower Lights

Machine Status Alert

The tower light provides detailed information about machine operational phases, not just errors. Example:

- Flashing Green: Machine is running but nearing cycle completion.

- Steady Yellow: Waiting for operator confirmation (e.g., needs material loading).

Reduced Operational Risk & Accidents

The tower light signal, especially Red light and Buzzer, is a critical part of machine safety procedures according to ISO 12100 standards. It ensures immediate warning to all personnel in the area about potential hazards (such as when a machine guard door is opened).

Production Efficiency Optimization (Lean – Andon System)

The tower light is the backbone of the Andon system (visual signaling mechanism in Lean Manufacturing). When workers notice an issue, they activate the tower light (pulling a cord, pressing a button) to immediately signal support teams (maintenance, technical). This allows for:

- Reduced Downtime: Shortening the response time to incidents.

- Increased OEE: Improving Overall Equipment Effectiveness by recording and analyzing machine downtime data.

Easy Remote Observation, Optimized Line Control

360-degree visibility and high brightness allow management to monitor dozens of machines simultaneously from the control center. This supports efficient prioritization of work and allocation of maintenance resources.

Classification of Modern Tower Lights

Classification by Tiers (1–5 tiers)

The choice of the number of tiers must be based on the complexity of the process being signaled:

- 1-Tier Light: Simple applications, typically indicating On/Off or a single warning (e.g., power indicator).

- 3-Tier Light: Ideal type for most basic production applications (Normal, Warning, Error).

- 4–5 Tier Lights: Reserved for processes requiring signaling of multiple auxiliary statuses (e.g., checking in progress, waiting for network communication, need for special material).

Classification by Signal Color

In addition to standard colors, some smart tower lights allow color customization (e.g., Patlite Multicolour) for flexibility with company-specific color codes.

Classification by Voltage

- Low Voltage (DC – 12V/24V): Standard in PLC-based automation systems. Ensures maximum electrical safety for installers.

- High Voltage (AC – 110V/220V): Used for standalone machinery, not routed through a PLC control system, or requiring direct connection to the main power grid.

Classification by Feature

- With Buzzer: Provides a dual warning signal. The buzzer can be a single-frequency tone or a Multi-tone Buzzer with the ability to select 7-8 different tones to differentiate errors.

- Smart Tower Lights (Network/IO-Link): Use industrial communication protocols (Ethernet/IP, Modbus TCP, IO-Link). This type allows remote control and data collection regarding the status of each light tier, strongly supporting IIoT (Industrial Internet of Things).

Classification by Manufacturer

- Patlite (Japan): A leader in innovation with products featuring high IP durability (IP65/66/67), easy-to-install modular design, and advanced network technology integration.

- Qlight (South Korea): Popular due to product variety, stable quality, and competitive pricing, suitable for many projects.

- Autonics / Hanyoung (South Korea): Offers economical solutions, readily available in the market.

Applications of Tower Lights in Industry

Automated Production Lines

Tower lights are placed at quality control stations, robotic assembly areas, and packaging machines to signal work status and support needs.

CNC Machines, Injection Molding Machines, Industrial Robots

Tower lights mounted on the machine top let supervisors immediately know the machine status: Red if a tool is broken (CNC), Yellow if plastic material is running low (Injection Molding), or Green if the cycle is running perfectly (Robot).

Control Cabinets

Signaling the cabinet’s operational status (Power On/Off, Power Fault, PLC Communication Error).

Warehouses – Operational Signal Alerts

Used as internal traffic lights. Example: at automatic rolling doors, Green signals a forklift can enter, Red signals the area is blocked or pedestrians are present.

Power Plants, Water Treatment, Pumping Stations

Water/corrosion-resistant (IP67) tower lights are used to warn of abnormal pressure, temperature, or chemical levels in the treatment system.

Guide to Choosing the Right Tower Light

Selection by Working Environment (Dust, Humidity, Vibration)

- IP Protection Rating (Ingress Protection):

- IP65: Complete dust protection and resistance to low-pressure water jets. Suitable for most production workshops.

- IP67: Complete dust protection and can be temporarily immersed in water. Mandatory for environments requiring frequent washing (food/pharmaceutical factories) or outdoor installation.

- Vibration Resistance: For high-speed machinery with strong vibrations, choose tower lights with special anti-vibration design.

Selection by Available Voltage

Always prioritize 24VDC as it is the standard voltage in industrial control systems and safer. Only use 220VAC when DC power is unavailable or when replacing old equipment.

Selection by Number of Tiers

Create a State Mapping chart before selecting:

- State 1: Machine Running (Green)

- State 2: Minor Error (Yellow)

- State 3: Machine Stop (Red)

- State 4: Waiting for Material (Blue)

If there are 4 states, you need a 4-tier tower light.

When is a Buzzer Needed?

A buzzer is necessary when:

- Observation distance is large (over 30m).

- The working environment has high background noise.

- Fire hazard or absolutely critical emergency situations need alerting.

Choosing Popular Tower Light Brands

Choosing a reputable brand ensures stability, long LED lifespan, and easy module replacement in case of failure.

Wiring Diagram and Guide for Tower Lights

Basic Wiring Principle: One Common wire and one dedicated Signal wire for each function (light color or buzzer).

Preparation Before Wiring

- Determine Polarity: DC lights (12/24V) need clear determination of Positive (+) and Negative (-) polarity.

- Check Common Wire: The COM wire can be connected to the positive terminal (+VDC) or negative terminal (0VDC), depending on the PLC’s Sourcing or Sinking control type.

2-Tier Tower Light Wiring Diagram (DC – 24V)

Assuming Sinking (NPN – Common is +VDC) wiring:

| Tower Light Connection | Control Cabinet/PLC Connection |

|---|---|

| Common Wire (COM) | +24VDC terminal of the power supply |

| Red Signal Wire | Output 1 (when Output 1 connects to 0VDC, Red light turns on) |

| Green Signal Wire | Output 2 (when Output 2 connects to 0VDC, Green light turns on) |

3-Tier Tower Light Wiring Diagram (DC – 24V)

Add one signal wire for the Yellow tier. Total 4 wires (COM + 3 Signals).

| Tower Light Connection | Control Cabinet/PLC Connection |

|---|---|

| Common Wire (COM) | +24VDC terminal of the power supply |

| Red Signal Wire | Output 1 (Signal) |

| Yellow Signal Wire | Output 2 (Signal) |

| Green Signal Wire | Output 3 (Signal) |

3-Tier with Buzzer Wiring Diagram

Requires a total of 5 wires (COM + 3 Light Signals + 1 Buzzer Signal). The buzzer wire is controlled independently of the light tiers, allowing the buzzer to sound even if no light is on (e.g., communication error alert).

| Tower Light Connection | Control Cabinet/PLC Connection |

|---|---|

| Common Wire (COM) | +24VDC terminal of the power supply |

| Red Signal Wire | Output 1 |

| Yellow Signal Wire | Output 2 |

| Green Signal Wire | Output 3 |

| Buzzer Signal Wire | Output 4 |

Safety Notes for Cabinet Wiring

- Power Off: Always ensure the main power is OFF before performing wiring.

- AC Wiring: For 220VAC tower lights, use an intermediate Relay to isolate the DC control circuit (PLC) from high AC voltage, avoiding the risk of PLC short-circuiting.

- Protection: Use terminal lugs (ferrules) and tighten screws securely at the terminal block to prevent looseness that could cause short circuits or heat generation.

Patlite Signal Tower Lights from Japan

Patlite Tower Lights

In the field of industrial signal tower lights, PATLITE (Japan) stands out as a global leader. PATLITE products are designed to meet the most demanding industrial standards, delivering exceptional performance in process management and monitoring. Their product lines, such as the LR series (LR5, LR6, LR7), are known for high durability, clear visibility, and integration of smart technologies.

Why Choose Patlite Tower Lights

Choosing Patlite tower lights offers strategic benefits for businesses:

- Japanese Quality: Ensures high durability, stable operation, and LED lifespan up to 50,000 hours—minimizing maintenance costs.

- Modern Technology: The LR-LAN (Network) series features Ethernet connectivity for remote monitoring and control, as well as OEE (Overall Equipment Effectiveness) data collection for IIoT systems.

- Environmental Durability: Made from premium materials with high IP protection (typically IP65), resistant to dust, water, and impact.

- Customization: Patlite offers a wide range of sizes, tiers, colors, and mounting options, easily integrating into existing systems.

Servo Dynamics Engineering: Authorized Patlite Distributor in Vietnam

In the field of Industrial Signal Tower Lights, PATLITE (Japan) is a pioneering brand, known for its network-integrated solutions, superior durability, and Japanese quality commitment.

To bring the world’s leading visual alert solution to Vietnamese businesses, Servo Dynamics Engineering is proud to be the official authorized distributor of PATLITE. We commit to providing genuine PATLITE products, from standard series like the LR Series to advanced lines like the LR-LAN (Network), along with expert technical consultation services and integration solutions into your IIoT system.

Tiếng Việt

Tiếng Việt