Consulting, Industrial Automation, News, Solutions

What Is Industrial Remote Access?

What is Industrial Remote Access?

What is Industrial Remote Access

Industrial Remote Access is a technology solution that allows engineers, operators, and maintenance experts to connect and control industrial devices remotely via the internet. This means you can monitor, control, and troubleshoot machinery and equipment in factories, power plants, or any other production facilities, even if you are not physically present there.

Components of a Remote Access System

Components of a Remote Access System

Components of a Remote Access System

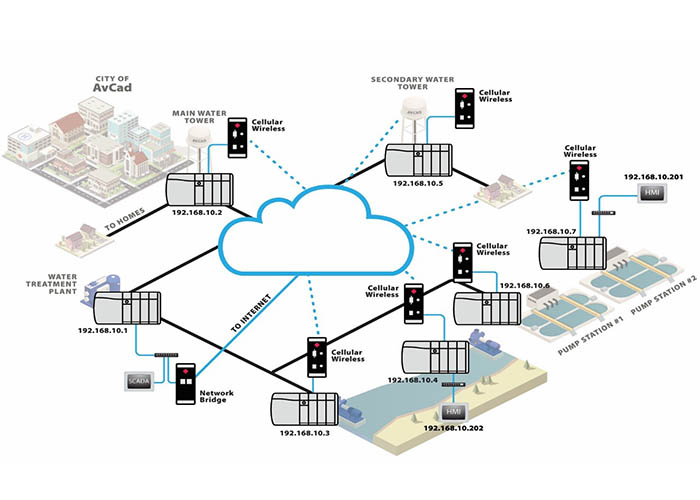

An industrial remote access system consists of various components connected together to form a network that allows monitoring and controlling industrial devices remotely. Below are the key components:

- End Devices:

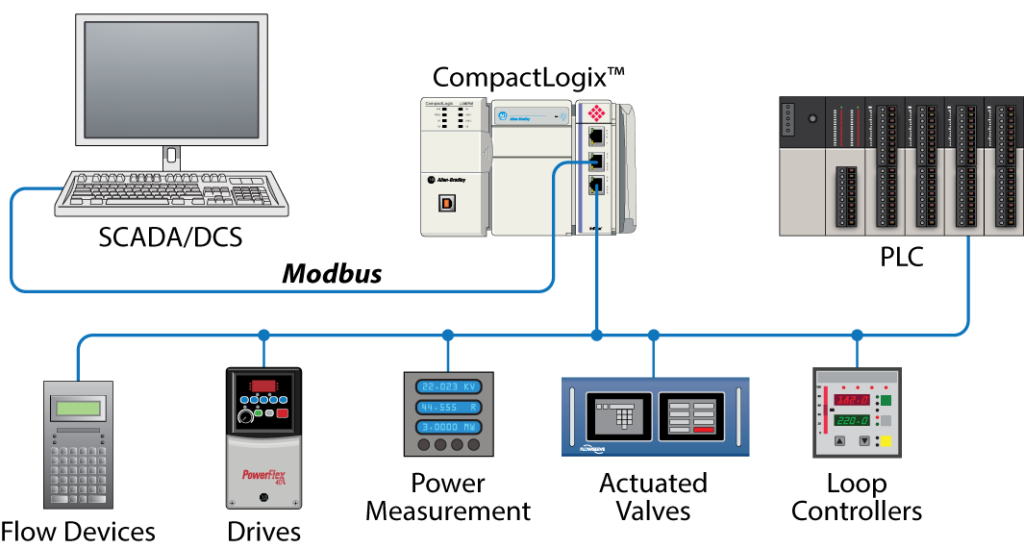

- PLC (Programmable Logic Controller): The “brain” of the system, which executes control commands and logic.

- HMI (Human Machine Interface): Allows users to interact directly with the system, including display screens, buttons, and other input devices.

- SCADA (Supervisory Control and Data Acquisition): A system for monitoring and collecting data, gathering information from devices and presenting it visually on screens.

- Sensors: Measure physical parameters such as temperature, pressure, flow, etc.

- Valves, motors: Devices that control the production process.

- Gateway:

- Function: Serves as a bridge between end devices and the communication network.

- Role: Converts different communication protocols, ensuring information is transmitted accurately and securely.

- Communication Network:

- Ethernet: A popular communication network providing high speeds and the ability to connect multiple devices.

- Wireless: A wireless network, convenient for areas where cable installation is difficult.

- VPN (Virtual Private Network): A private network ensuring the security of transmitted data.

- Software:

- Monitoring Software: Displays data from devices, allowing users to monitor the production process.

- Control Software: Allows users to control devices remotely.

- Configuration Software: Configures devices and systems.

- Security Software: Protects the system from external attacks.

- Server:

- Data Storage: Stores data collected from devices.

- Data Processing: Processes data and generates reports.

- Service Provision: Provides services to other devices within the system.

Benefits of Industrial Remote Access

Industrial remote access offers significant benefits to manufacturing businesses. Here are some key benefits:

Enhanced Production Efficiency:

- Minimizes Downtime: When issues arise, technicians can quickly connect remotely to diagnose and fix the problem, minimizing machine downtime.

- Optimizes Production Processes: Based on data collected from the system, engineers can adjust operating parameters for optimal performance.

- Improves Overall Equipment Efficiency (OEE): By remotely monitoring and controlling the production process, companies can enhance OEE, thus improving productivity and product quality.

Cost Reduction:

- Reduces Maintenance Costs: Early detection and troubleshooting help minimize damage and repair costs.

- Reduces Travel Costs: Technicians no longer need to travel on-site to address minor issues, saving time and money.

- Optimizes Energy Usage: By monitoring and controlling energy consumption remotely, companies can reduce operational costs.

Improving Safety:

- Early Detection of Potential Issues: The remote monitoring system can detect unusual signs early, helping prevent serious issues.

- Reducing Risks for Employees: Performing maintenance and repair tasks remotely helps minimize the risk of workplace accidents.

Improving Customer Service:

- Quick Customer Support: Technicians can provide fast support to customers regardless of their location.

- Enhancing Customer Satisfaction: Excellent customer service leads to greater customer loyalty.

Flexibility and Convenience:

- Working Remotely: Technicians can work from any location with an internet connection.

- Accessing Information Anytime, Anywhere: Production data is continuously updated and can be accessed from any device.

Enhancing Competitiveness:

- Responding Quickly to Market Demands: Businesses can quickly adapt to market changes.

- Improving Business Image: A modern, technology-driven company attracts more customers.

Applications of Remote Access in Industry

Industrial Remote Access offers a wide range of practical applications across different industries. Below are some key applications:

Monitoring and Controlling the Production Process:

- Monitoring Parameters: Track temperature, pressure, flow, liquid levels, etc., to ensure stable production processes.

- Controlling Devices: Remotely control valves, motors, and pumps to adjust process parameters.

- Optimizing Processes: Analyze collected data to identify areas for improvement and optimize production processes.

Predictive Maintenance:

- Early Detection of Abnormal Signs: Analyze data to detect signs of equipment failure before they cause significant problems.

- Maintenance Scheduling: Based on analyzed data, schedule regular maintenance to minimize downtime and extend equipment lifespan.

Training and Technical Support:

- Remote Training: Experienced engineers can train new employees remotely at different locations.

- Online Technical Support: Provide direct technical support to customers or remote plants.

Data Collection and Analysis:

- Big Data Collection: Collect large volumes of data from sensors and devices for analysis.

- Data Analysis: Use data analytics tools to identify trends, correlations, and other useful information.

- Optimizing Decision-Making: Based on analyzed data, make better business decisions.

Other Applications:

- Energy Management: Monitoring and controlling energy consumption to reduce costs.

- Safety and Security: Monitoring security systems and detecting threats.

- Quality Control: Monitoring product quality throughout the production process.

Challenges of Remote Access in Industry

Cybersecurity:

- Risk of Attacks: Remote access systems are an attractive target for hackers, which may lead to data theft, system damage, or serious disruptions.

- Protecting Sensitive Data: Production data is often sensitive and must be protected from unauthorized access.

- Cyber Attacks: Attacks such as DDoS, malware, and other security vulnerabilities can disrupt production operations.

Reliability:

- Unstable Network Connection: Loss of network connectivity can disrupt remote monitoring and control processes.

- Hardware and Software Failures: Failures in equipment or software can impact the operation of the system.

- Latency: Data transmission latency can cause issues when controlling real-time devices.

Compatibility:

- Protocol Differences: Different industrial devices often use different communication protocols, making integration challenging.

- Platform Differences: Devices may run on different operating systems and hardware platforms.

- Software Updates: Updating software for older devices may cause compatibility issues.

Costs:

- Initial Investment Costs: Implementing remote access systems requires a significant investment in hardware, software, and services.

- Maintenance Costs: The maintenance costs of the system, including hardware and software, are also significant.

- Training Costs: Employees need to be trained to effectively use the system.

Other Issues:

- Legal Regulations: Implementing remote access systems must comply with information security and industrial safety regulations.

- System Complexity: Industrial production systems are often very complex, and integrating remote access into the existing system may encounter difficulties.

How to Choose the Right Remote Access Solution

Choosing the right remote access solution is critical to ensuring the efficiency and safety of your industrial system. Below are some factors to consider when making the decision:

Assessing Needs:

- Usage goals: What do you want to use remote access for? Monitoring, control, maintenance, or training?

- Number of devices: How many devices do you need to access?

- Device type: Are your devices compatible with the remote access solution?

- Bandwidth: How much bandwidth do you need to ensure a quality connection?

Identify Necessary Features:

- User interface: Is the interface easy to use and user-friendly?

- Security: Does the solution ensure high security and protect data from unauthorized access?

- Scalability: Can the solution scale to meet future needs?

- Integration: Can the solution integrate with your existing systems?

Compare Solutions:

- Software: Compare features, interfaces, and pricing of different remote access software.

- Hardware: Evaluate the necessary gateways, routers, and other networking devices.

- Vendors: Research the reputation, experience, and support services of the vendors.

Other Factors to Consider:

- Cost: Assess initial investment and annual operating costs.

- Complexity: Is the solution easy to install and use?

- Implementation time: How much time is needed to implement the solution?

Prosoft Technologies’ Remote Access Solutions

Prosoft Technologies’ Remote Access Solution

ProSoft offers an outstanding remote connection solution for the industry, helping businesses reduce downtime, optimize support costs, and use resources more efficiently. With over 30 years of experience, ProSoft continuously improves to provide secure, simple, and easy-to-use connection technology, enabling device management from anywhere in the world.

Key Benefits:

- Minimizes machine and production process downtime

- Reduces remote technical support costs

- Optimizes support resources for multiple customers simultaneously

Security Features:

- Two-factor authentication based on tokens

- Configurable password policies

- Access management based on user roles and devices

- Supports Active Directory via Single Sign-On

- Virtual Lockout-Tagout

- Secure VPN Tunneling connection

Simplified Features:

- No installation or software maintenance required

- EasyBridge technology connects devices without complex routing

- Data Logger collects information without putting pressure on the internal network

With ProSoft, businesses can effectively manage devices remotely, minimize risks, and optimize operations, anytime and anywhere.

Servo Dynamics – Official Distributor of ProSoft Technologies in Vietnam

Servo Dynamics is the official distributor of ProSoft Technologies, bringing advanced remote connection solutions to the industrial sector in Vietnam. With a commitment to providing modern technology, high security, and easy deployment, we help businesses optimize their operations and minimize downtime.

Tiếng Việt

Tiếng Việt