Solutions, Industrial Automation, News

What is fiber optic cable and how does it work?

What is Fiber optic cable?

Fiber optic cable is defined by an optical fiber, strength members and outer jacket. The optical fiber transmits the signal, the strength member provides tensile and crush resistance, and the jacket protects the overall cable from the environment.

Unlike the copper used in Category or Ethernet cables, which transmit data using electrical signals, optical fiber uses glass as a transmission medium for fast-traveling pulses of light. The basic signal-transmission process requires a transmitter, a receiver and an optical fiber made of glass as a way to transmit the light from the transmitter to the receiver.

Optical fiber is manufactured using a two-step process. The first step consists of producing pure glass to create a preform. To make this happen, various doping gases are used to add layers of pure glass to a cylinder. The purity of the glass is critical so it can transmit light across long distances without losing information.

The second step is called “fiber draw.” Here, the preform is heated and pulled to reduce the diameter into a thin optical fiber. The size of a standard optical fiber is 250 microns. For size reference, a human hair is about 100 microns. This process is similar how confectionaries make tiny designs with their hand-rolled candies—except the large glass cylinder is heated to its melting point and pulled, not rolled, to get the desired geometries.

The resultant optical fibers are arranged in bundles with strength members and/or buffer materials inside an outer jacket.

Components of Optical Fibre Cables

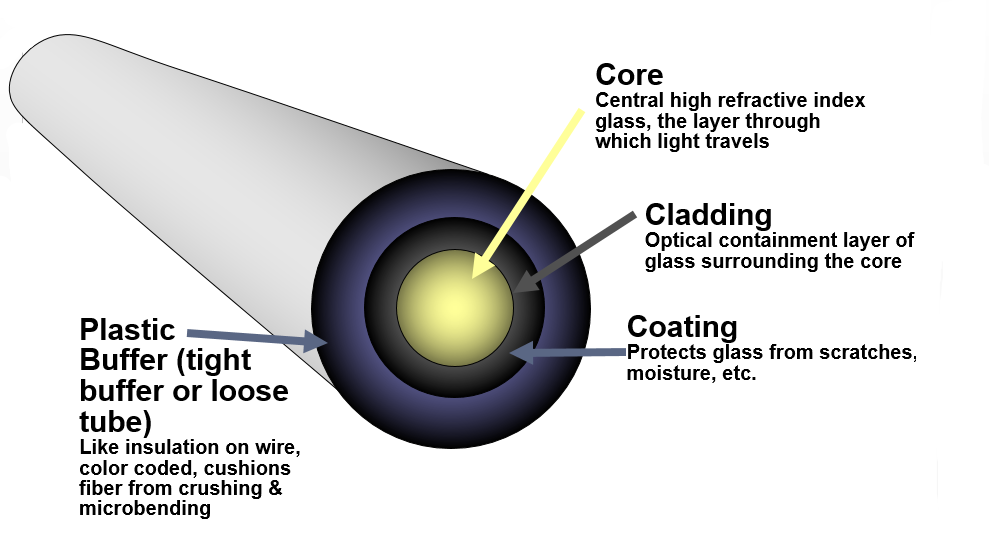

Optical fiber is composed of a core, a cladding and a coating. These are called the “three Cs.”

Core

First is the “core” or glass structure, which is how the light travels down the cable to a receiving device. As it travels, the optical signal is propagated in the core through total internal reflection. The light is reflected at the interface between the core and cladding (which is the component we’ll discuss next).

The light signals are carried in paths that the light beam follows when traveling down the fiber. These paths are also called “modes.”

Cladding

Wrapped around the core is a thin layer of glass called “cladding.” It acts as a boundary that keeps light signals inside the core. Think of this as a perfectly reflecting mirror surface. This allows data to travel through the entire length of the fiber to reach the receiver.

Coating

In many cases, two UV-cured coating layers are applied on the top of the cladding. Called the “coating,” this dual layer protects the glass from scratch, microscopic bending, and contaminants. Fibers are glass, and this extremely thin and fragile material requires these protective materials to survive both manufacturing and end-user handling.

The overall cable construction then packages the optical fiber to meet requirements, which vary based on applications and regions.

Fiber optic cables also include two other components:

Strength members

To give strength to a cable during installation, materials such as steel, aramid fiber, fiberglass yarn or a stiff fiberglass rod are used to enhance tensile strength and crush resistance. They help the fiber optic cable withstand pulling, bending, rolling, torsion and other forces.

Jacket

As the outer layer of the cable, the jacket acts as the cable’s first line of defense against its surrounding environment. Different jackets are available to protect against external factors like sharp objects. These can also be flame-retardant in nature, depending on the application, such as indoor risers or air plenums.

Types of fiber optic cables

There are two types of fiber optic cable: singlemode and multimode—and each one of these optical fibers work a little differently.

Singlemode Fiber Optic Cable

Singlemode fiber cables are designed with a very small core size that allows only a single light mode to pass through. This design minimizes light reflection and significantly reduces signal attenuation, making singlemode fiber ideal for long-distance transmissions.

Key Features of Singlemode Fiber:

-

Core Size: Smaller diameter (about 9 microns).

-

Distance: Supports very long transmission distances with virtually no distance limitations.

-

Bandwidth: High bandwidth capabilities with minimal signal loss.

-

Applications: Long-haul communication like inter-campus, undersea, and remote office connections.

-

Cost: The cable itself is generally less expensive, but the transceivers are typically pricier compared to multimode.

Types of Singlemode Fiber:

-

G.652: Standard singlemode fiber; low water peak versions available.

-

G.653: Dispersion-shifted fiber, optimized for specific wavelengths.

-

G.654: Cutoff-shifted fiber for ultra-long-haul networks.

-

G.655: Non-zero dispersion shifted fiber (NZDSF) for dense wavelength division multiplexing (DWDM) systems.

-

G.657: Bend-insensitive fiber, designed to reduce losses from sharp bends.

Each type of singlemode fiber has specific characteristics depending on the operating wavelengths, distances, and system architecture.

Multimode Fiber Optic Cable

Multimode fiber cables have a much larger core diameter, allowing multiple light modes to travel simultaneously. While this design supports the use of less expensive optical devices, it introduces modal dispersion, limiting transmission distance and bandwidth.

Key Features of Multimode Fiber:

-

Core Size: Larger diameter (50 or 62.5 microns).

-

Distance: Best suited for short-distance applications.

-

Bandwidth: High bandwidth over short distances; limited reach at higher bandwidths due to modal dispersion.

-

Applications: Local area networks (LANs), data centers, and enterprise networks.

-

Cost: The cable and associated transceivers are generally more cost-effective for short distances.

Types of Multimode Fiber (OM Series):

-

OM1: 62.5-micron core, supports up to 1 Gbps over 300 meters.

-

OM2: 50-micron core, supports up to 1 Gbps over 600 meters.

-

OM3: Laser-optimized, supports 10 Gbps over 300 meters.

-

OM4: Higher performance version of OM3, supports 10 Gbps over 550 meters.

-

OM5: Optimized for emerging wideband multimode fiber (WBMMF) applications and shortwave wavelength division multiplexing (SWDM).

How Each Fiber Cable Type Works

Multimode fiber uses a relatively large core that allows multiple light beams (or “modes”) to travel through the cable at the same time but along different paths. Because each light mode can take a slightly different route, they arrive at the destination at slightly different times.

This effect, called modal dispersion, can cause signal distortion over longer distances. Multimode fiber works best when used over shorter lengths, where the delay between light modes remains minimal and does not affect signal clarity.

Modern multimode fibers, like OM3, OM4, and OM5, are optimized with laser sources such as LEDs or VCSELs to better align the modes and reduce dispersion. Technologies like short wavelength division multiplexing (SWDM) in OM5 allow multiple laser signals to be transmitted at once, further improving how data flows through the fiber by efficiently utilizing available light wavelengths.

Singlemode fiber, in contrast, uses a very narrow core that allows only one light mode to pass straight down the fiber. By restricting the light to a single, direct path, singlemode fiber eliminates modal dispersion completely.

Since there’s only one path for light to travel, all parts of the light pulse move uniformly and arrive at the receiver at the same time. This results in extremely low signal loss and distortion, even over very long distances, making singlemode fiber ideal for long-haul transmissions such as cross-campus links, undersea cables, and telecommunications backbones.

Benefits of Fiber Optic Cable

Fiber optic cable provides key advantages that make it the leading choice for high-performance network infrastructure. Here’s how fiber stands out:

1. Fiber Supports Very High Bandwidth Levels

Fiber optic cables, especially singlemode, offer the highest available bandwidth, carrying far more data than copper cables of the same diameter.

The cable itself isn’t the limitation—it’s the electronics connected to it. As technology advances, upgrading transceivers and other components allows you to maximize fiber’s potential without replacing the cable.

Additionally, fiber reduces latency, enabling faster downloads, quicker uploads, and smooth access to resources across both short and long distances.

2. Fiber is Inherently Secure

Fiber cables are highly secure because they don’t radiate signals that can be intercepted.

Tapping into a fiber cable requires physically accessing and cutting into it, which typically brings down the network and triggers immediate alerts—making unauthorized access extremely difficult.

3. Fiber is Intrinsically Safe

Since fiber transmits data via light rather than electricity, it is safe to handle, eliminating the risks associated with electrical cables like sparks, shocks, or fires.

4. Fiber Withstands Water and Temperature Fluctuations

Fiber optic cables are resistant to environmental challenges such as moisture, rain, and extreme temperatures.

Even in severe weather or when exposed to lightning, fiber performance remains unaffected because it contains no metallic elements to conduct electricity. This makes it ideal for outdoor, industrial, and long-distance applications.

5. Fiber is Immune to EMI

Unlike copper cables, fiber does not carry electric current and is completely immune to electromagnetic interference (EMI) and crosstalk.

This ensures stable, uninterrupted data transmission, even in environments with dense electronic equipment.

Developing optical fiber components for more than 50 years, Belden is a leading supplier of high-quality, cost-effective fiber cabling systems. Our FiberExpress Ultra High Density (FX UHD), FX ECX (FiberExpress Enterprise Closet X) and DCX Systems are the culmination of decades of experience and expertise across a variety of applications, including data centers, premise and campus network backbone infrastructures, fiber-to-the-desk (FTTD) and horizontal and centralized cabling systems.

Servo Dynamics – An authorized distributor of Belden in VietNam

Servo Dynamics is proud to be an authorized distributor of Belden in Vietnam, delivering world-class cabling and connectivity solutions to the local market. As a trusted partner, we offers Belden’s full range of high-performance products, including fiber optic cables, industrial Ethernet solutions, and network accessories. With a strong commitment to quality, innovation, and customer service, our team ensures that businesses in Vietnam have access to the reliable, cutting-edge technology they need to power their operations and stay connected in today’s fast-paced digital world.

Learn more

Tiếng Việt

Tiếng Việt