Consulting, News, Solutions

What is an Industrial Communication Network? Types and Applications

In modern manufacturing environments, the ability to quickly connect and transfer data between devices is crucial for improving efficiency and minimizing disruptions. However, not all businesses fully understand the role of industrial communication networks and how to choose the right system. This article will provide a detailed explanation of industrial communication networks, common types, and practical applications to help businesses optimize their production processes.

What is an Industrial Communication Network?

An Industrial Communication Network is a specialized network designed to connect devices and systems within an industrial environment. Unlike conventional computer networks, industrial communication networks must meet stringent requirements for reliability, real-time performance, and operation in harsh environments.

Industrial Communication Network Architecture

An industrial communication network comprises various components, each playing a crucial role in ensuring efficient and reliable operations in the production process:

Field Devices: These are devices that directly interact with the production process, collecting data and executing actions. Examples: Sensors (temperature, pressure, flow), actuators (controlling valves, motors), switches, valves, etc.

Controllers: Controllers act as the “brain” of the industrial communication network, processing data from field devices and making control decisions. Examples: PLC (Programmable Logic Controller), DCS (Distributed Control System).

Network Devices: Network devices ensure connectivity and data transmission among various components in the network. Examples: Switches, routers, gateways.

Software: Software provides user interfaces and tools for monitoring, controlling, and managing the industrial communication network. Examples: SCADA (Supervisory Control and Data Acquisition), HMI (Human-Machine Interface).

Communication Protocols: Communication protocols define how devices in the network exchange data with each other. Examples: Modbus, Profibus, Ethernet/IP.

Industrial communication networks play a crucial role in connecting and transmitting data between devices and systems in manufacturing and automation environments. Below are the key roles:

- Enhancing production efficiency: Industrial communication networks enable seamless connectivity between devices and systems within factories, optimizing production processes, reducing downtime, and increasing productivity.

- Improving product quality: Real-time data from sensors and devices allow precise and efficient quality control. Additionally, early detection of errors and failures in the production process helps prevent defective products.

- Reducing operational costs: Automating processes helps cut labor costs, electricity expenses, and other resources, optimizing energy usage.

- Enhancing workplace safety: Industrial communication networks enable remote monitoring and control of production processes, minimizing workplace hazards. Connected sensors help detect toxic gases and other dangers, providing timely warnings to workers.

- Supporting decision-making: Real-time data from industrial communication networks provide critical information for business decision-making.

Types of Industrial Networks

There are various types of industrial communication networks, each with its own advantages and disadvantages. Below are some of the most common types:

-

Industrial Ethernet Communication Network

Industrial Ethernet communication networks use standard Ethernet protocols, allowing high-speed data transmission and excellent compatibility with conventional network devices. This is a popular choice for applications requiring high bandwidth and flexible connectivity. Some notable industrial Ethernet variants include Ethernet/IP, Profinet, and EtherCAT, which optimize performance in manufacturing and automation environments.

-

Modbus Industrial Communication Protocol

The Modbus industrial communication protocol is a simple and widely used serial communication protocol in the industry due to its ease of implementation, maintenance, and low cost. However, Modbus has limitations in data transmission speed and scalability, making it more suitable for systems that do not require high-speed data transfer.

Serial Communication Network

The serial communication network uses protocols such as RS-232 and RS-485, suitable for long-distance data transmission at low speeds. This is a simple, cost-effective solution that is easy to integrate into industrial systems. However, due to its speed and connectivity limitations, serial communication is mainly used in applications that do not require high bandwidth.

-

DeviceNet Industrial Communication System

The DeviceNet industrial communication system is built on the CAN (Controller Area Network) protocol and plays an important role in factory automation applications. DeviceNet is suitable for connecting field devices such as sensors and actuators, offering strong noise resistance and high reliability in harsh industrial environments.

-

Profibus Communication Network

The Profibus communication network is a widely used protocol in process automation and factory automation. With the ability to support various devices and applications, Profibus allows flexible connections, easy system expansion, and ensures high operational reliability in industrial environments.

-

HART Communication Protocol

The HART (Highway Addressable Remote Transducer) communication protocol is widely used in industrial process automation applications. This protocol enables two-way communication between smart field devices and control systems, supporting remote configuration, calibration, and device monitoring. By combining both analog and digital signals, HART provides flexibility in managing and operating modern industrial systems.

Hierarchy Levels in Industrial Communication Networks

Industrial communication networks are typically divided into three levels:

Information Level:

- Involves collecting, processing, and analyzing data from production systems.

- Uses protocols such as Ethernet/IP, OPC UA, etc.

- Applications: SCADA, MES (Manufacturing Execution System), ERP (Enterprise Resource Planning).

Control and Supervision Level:

- Involves controlling and monitoring production processes.

- Uses protocols such as Profibus, Modbus TCP, etc.

- Applications: PLC, DCS, HMI.

Device and Field Level:

- Involves connecting field devices such as sensors, actuators, etc.

- Uses protocols such as DeviceNet, Modbus RTU, etc.

Industrial Communication Networks with Other Network Types

Industrial Communication Networks vs. Computer Networks:

Real-time Processing:

- Industrial Networks: Require real-time data processing and transmission to ensure synchronization and accuracy in manufacturing processes.

- Computer Networks: Prioritize bandwidth and data transfer speed, without strict real-time processing requirements.

Reliability and Durability:

- Industrial Networks: Designed to operate in harsh environments (high temperatures, dust, vibrations), ensuring high reliability.

- Computer Networks: Typically operate in office environments with lower durability requirements.

Protocols:

- Industrial Networks: Use specialized protocols (Modbus, Profibus, EtherNet/IP) to ensure stability and compatibility with industrial equipment.

- Computer Networks: Use standard protocols (TCP/IP).

Industrial Communication Networks vs. Telecommunication Networks:

Bandwidth and Transmission Speed:

- Industrial Networks: Bandwidth requirements vary by application, but low latency is essential.

- Telecommunication Networks: Focus on high bandwidth to support multimedia data transmission.

Security and Latency:

- Industrial Networks: Require high security to protect critical production data and low latency to ensure stable operations.

- Telecommunication Networks: Focus on user data security, with acceptable latency in some cases.

Environmental Tolerance:

- Industrial Networks: Designed to withstand harsh environmental conditions.

- Telecommunication Networks: Typically housed within specialized telecom infrastructure.

Applications of Industrial Communication Networks

Industrial communication networks are widely applied across various industries, enhancing efficiency and productivity. Below are some key applications:

Manufacturing Automation:

- In production plants, industrial communication networks connect devices such as PLCs, robots, and sensors to form a complete automation system.

- This optimizes production processes, reduces errors, and increases productivity.

Energy Industry:

- In power plants, industrial networks are used for monitoring and controlling equipment to ensure safe and efficient operations.

- In the oil and gas sector, these networks monitor and control offshore rigs, pipelines, and other critical infrastructure.

Transportation Industry:

- In intelligent transportation systems, industrial networks connect traffic lights, surveillance cameras, and other devices to improve traffic coordination.

- In rail transport, these networks monitor and control signaling systems to ensure passenger safety.

Food and Beverage Industry:

- In food processing plants, industrial networks monitor and control temperature, humidity, and other factors to ensure product quality.

- In bottling plants, they automate packaging processes, increasing production efficiency.

Chemical Industry:

- Industrial networks are used to monitor chemical processes, control reactions, and ensure safety.

Rockwell Automation Networking Solutions: Smart Connectivity for Automated Factories

Rockwell Automation offers a wide range of devices, communication interfaces, physical media, and connectivity products to help you maximize your control system. Rockwell’s solutions include:

EtherNet/IP Network

Rockwell’s EtherNet/IP™ network provides plant-wide networking systems using industry-standard, open technologies. It enables real-time control and information exchange across discrete, continuous process, batch, safety, drive, motion, and high-availability applications.

EtherNet/IP connects devices such as motor starters and sensors to controllers and HMIs while integrating seamlessly with enterprise networks. It supports both industrial and non-industrial communications on a common network infrastructure.

ControlNet Network

Rockwell’s ControlNet™ network is an open industrial network designed for high-speed, real-time control applications. It supports controller-to-controller communication and real-time control of I/O, drives, and valves. ControlNet is ideal for discrete and process applications, including those requiring high availability.

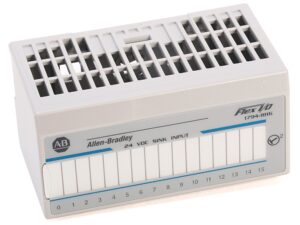

DeviceNet Network

Rockwell’s DeviceNet™ network offers an open, device-level information and control network for simple industrial devices. It facilitates communication between sensors and actuators with higher-level controllers and computers. With power and data transmitted over a single cable, DeviceNet provides simplified wiring and cost-effective installation.

Gateway & Linking Devices

Rockwell provides a variety of Gateway and Linking Devices to seamlessly connect information-level or control-level networks with device-level networks. This reduces control equipment costs by leveraging existing network infrastructures to access data across different networks.

Other Industrial Networks

Rockwell supports various other industrial automation networks, providing flexibility to integrate new applications with existing systems. These networks include Data Highway Plus, DH-485, Universal Remote I/O, and SERCOS II.

Process Instrumentation Networks

Rockwell offers integrated support for PlantPAx™ Distributed Control Systems using HART and FOUNDATION™ fieldbus devices. Our Encompass™ Partners extend support for Profibus PA, Modbus, and other networks. Endress+Hauser and other partners now provide process measurement devices that connect with EtherNet/IP™ to support this growing trend.

Servo Dynamics – Official Distributor of Rockwell Automation in Vietnam

Servo Dynamics is proud to be the official distributor of Rockwell Automation in Vietnam. With an experienced team of experts deeply knowledgeable in industrial networking solutions, Servo Dynamics is committed to providing high-quality products and services to meet the diverse needs and challenges of digital transformation and industrial automation.

Tiếng Việt

Tiếng Việt