Consulting, Industrial Automation, News, Solutions

What is a Servo Motor? Types, Components, and How it works

Nowadays, servo motors have become one of the indispensable solutions, especially in industries that require high precision such as robotics, CNC machines, and automated manufacturing. With flexible motion control capabilities, fast response, and superior efficiency, servo motors offer many advantages that far surpass traditional motors.

This in-depth article will provide a comprehensive overview of servo motors, from definitions, structure, and operating principles to detailed control techniques and practical experience in selecting the right product. Let’s dive in!

What is a Servo Motor?

Definition of a servo motor

Servo Motor is a special type of electric motor designed to precisely control motion parameters such as position, velocity, and torque.

Unlike conventional motors that only operate with simple on/off commands, a servo motor is a core component in a closed-loop control system. This system includes the motor, encoder, and driver circuit working in synchronization to continuously monitor and correct errors, ensuring the motor always reaches the desired state as commanded.

What is a servo motor used for?

Servo motors are used to perform repetitive, precise, and programmable motions. Their main functions are:

- Position control: Move the motor shaft to a specific rotation angle or linear position with very high accuracy (often within ±0.01 degrees).

- Speed control: Maintain a stable rotational speed or change speed according to a predefined profile (e.g., smooth acceleration).

- Torque control: Provide a specific torque independent of speed.

Differences between a Servo Motor and a conventional motor

| Characteristics | Servo Motor (Closed-Loop) | Conventional Motor (Open-Loop) |

|---|---|---|

| System | Closed-loop (with feedback) | Open-loop (no feedback) |

| Accuracy | Very high, can continuously compensate for errors. | Lower, prone to step loss/error under overload. |

| Control | Position, speed, torque. | Speed only (based on frequency/voltage). |

| Speed/Torque | High torque at low speed/start-up. | Torque drops quickly as speed increases. |

| Applications | CNC machines, robots, medical equipment, printing. | Pumps, fans, simple conveyors. |

Common applications in industry & automation

Servo motors are widely used in industries that require high precision and flexibility:

- Robots and robotic arms: Controlling joints.

- CNC machines (Computer Numerical Control): Controlling X, Y, Z axes.

- Packaging and printing equipment: Require synchronized motion and high speed.

- Medical equipment: X-ray machines, ultrasound machines, surgical robots.

Servo Motor Structure

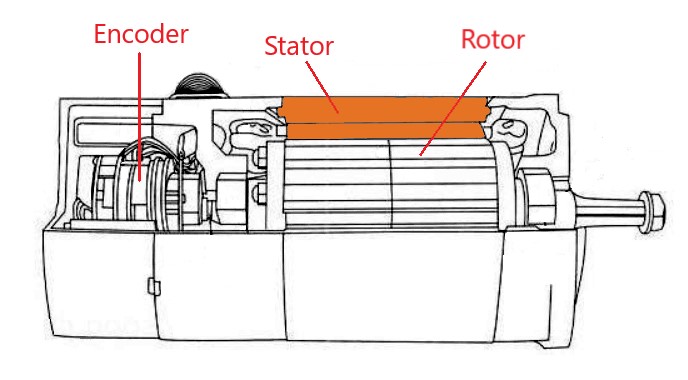

A servo motor is an integrated system that includes multiple components working together to create highly accurate motion.

DC servo structure

DC servos typically use brushed or brushless DC motors (BLDC). They are common in small and medium power applications that require fast response and often come with an integrated gearbox.

AC servo structure

AC servos use asynchronous AC motors or permanent magnet synchronous motors. They dominate in heavy-duty industrial applications with high power, high torque, and outstanding durability.

SG90 servo structure (mini servo commonly used with Arduino)

SG90 is a popular micro servo:

- Small DC motor (Brushed DC motor): Provides rotational force.

- Plastic gearbox: Reduces speed and increases torque.

- Potentiometer: Acts as a simple mechanical position sensor instead of an encoder, used to feed back shaft position.

- Control circuit: Receives PWM signals from Arduino/microcontroller and adjusts the motor.

Key components:

| Component | Main function | Role in closed-loop |

|---|---|---|

| Motor (AC/DC/BLDC) | Converts electrical energy into mechanical energy. | Generates the required motion according to commands. |

| Encoder | Measures the actual rotation angle, speed, and position of the shaft. | Provides feedback signals about the current position. |

| Gearbox | Reduces speed, increases torque, improves resolution. | Helps the motor achieve higher torque required to move the load. |

| Control board (Driver/Amplifier) | Receives commands, compares, calculates error, adjusts current. | The “brain” of the system, performs closed-loop control. |

| Brake (servo with brake) | Holds the motor shaft stationary when power is lost or at rest. | Ensures safety and maintains vertical load position. |

| Power/signal/cables | Transmit power and data between motor and driver. | Ensure integrity of feedback signals from the encoder. |

Operating Principle of a Servo Motor

The core operating principle of a servo motor is the closed-loop control system, as opposed to the open-loop system of conventional motors.

How a servo controls position

- Receiving the command (Input): The controller (PLC, microcontroller, etc.) sends a command signal (Set Point) for the desired position (e.g., 90 degrees or 1000 pulses).

- Measurement (Feedback): The encoder mounted on the motor shaft measures the actual position (P_actual) and sends the feedback signal to the driver.

- Comparison (Error Calculation): The driver calculates the error (E) using the formula: Error (E) = Desired position (P_set) – Actual position (P_actual).Formula: E = P_set – P_actual

- Correction: If E is not zero, the driver adjusts the current supplied to the motor.

- If E > 0 (position not yet reached), the motor continues to rotate.

- If E < 0 (overshoot), the motor reverses or decelerates.

- Repeat: This process occurs continuously, ensuring E always approaches 0, helping the motor reach the desired position with maximum accuracy.

Speed & torque control

Besides position control, a servo driver can also control speed and torque:

- Speed control: The driver uses speed feedback from the encoder (derived from position) and adjusts voltage/frequency to maintain the commanded speed.

- Torque control: The driver controls the current through the motor windings. The higher the current, the higher the torque. This is useful in applications that require force limiting (e.g., screw tightening, sensitive packaging).

Encoder feedback & control loop

The encoder is the key factor determining servo accuracy. Depending on the encoder type (Incremental or Absolute) and resolution (e.g., 20 bits/rev), the driver can calculate position and speed with millisecond-level precision.

Operating principle of an AC Servo

Servo motors operate based on the principle of a closed-loop system. This means the motor not only executes a command but also continuously compares the actual result with the original command to make suitable adjustments.

The specific operation process is as follows:

- Command input: The servo motor receives a control signal from a controller (PLC, computer, etc.). This signal specifies the desired position, speed, or torque that the motor must achieve.

- Comparison: The internal controller of the servo motor compares this signal with the actual position of the motor shaft. The actual position is measured by an encoder mounted on the motor shaft.

- Adjustment: If there is a deviation between the desired position and the actual position, the controller calculates and sends a new control signal to the motor to minimize this error.

- Execution: The motor adjusts its speed and direction of rotation to reach the desired position.

- Repetition: The process of comparison and adjustment is repeated continuously to ensure the motor is always at the correct position and speed.

A servo motor operates on the principle of continuously comparing the desired position with the actual position, then adjusting to minimize the error. Thanks to this, the servo motor achieves high accuracy and fast response to control requirements.

Servo Motor Types

Servo motors are classified based on various criteria, helping users easily choose the type that best suits their application.

AC Servo

- What is an AC servo: A motor that uses AC power, typically brushless (Brushless AC Motor) or PMSM.

- Characteristics – advantages:

- High torque, suitable for heavy loads.

- High durability, low maintenance (no brushes).

- High speed and outstanding load capacity.

- Used in most modern machine tools and industrial robots.

DC Servo

- What is a DC servo: A motor that uses DC power, which can be brushed DC or brushless DC (BLDC).

- Characteristics: Usually compact, fast response, easy to control, low cost, suitable for low- and medium-power applications (mini robots, handheld devices).

BLDC Servo

- BLDC Servo (Brushless DC): A segment of DC servo that uses a brushless drive mechanism (similar to AC servos), eliminating wear issues and increasing service life.

Servo by rotation angle:

- 90-degree, 180-degree, 360-degree (Continuous Rotation Servo): This classification mainly applies to mini servos (such as SG90) used in DIY projects.

- 90° / 180°: Can only rotate within a fixed angle range.

- 360° (continuous rotation): Operates like a normal DC motor, but speed is controlled by a position signal (PWM).

Servo by power rating:

- Servo 200W, 400W, 750W, high power: Power is the most important factor. The higher the power, the higher the torque and load capacity.

Geared vs non-geared servos

- Geared: Improves output torque and fine angular resolution, but may reduce maximum speed.

- Gearless (Direct Drive): High speed, no gearbox backlash, extremely high accuracy, but lower torque.

Comparison between stepper motor and servo motor

These are two common position control solutions:

| Characteristics | Servo Motor | Stepper Motor |

|---|---|---|

| System | Closed-loop (feedback is mandatory) | Open-loop (common) or closed-loop (hybrid) |

| Accuracy | Maintained under all load conditions. | Prone to step loss (slip) under overload/fast acceleration. |

| Speed | Very high (up to 6000 rpm). | Low (performance drops after about 1000 rpm). |

| Cost | Higher (both motor and driver). | Lower. |

Applications of Servo Motors

Servo motors are the “heart” of automation systems that require absolute precision.

In industrial machinery

- CNC machines/machine tools: Control the speed and position of spindles and motion axes (X, Y, Z) to machine parts with extremely tight tolerances.

- High-precision conveyor systems: Synchronously control conveyors to position products or change speed as needed.

- Printers and laser/Plasma cutters: Control the movement speed of the print/cutting head to ensure quality.

In electrical control panels

Servo drivers are an essential part of automation panels, connected to PLCs (Programmable Logic Controllers) via industrial communication protocols (EtherCAT, Profinet, Modbus, etc.) to receive and execute commands.

In robots – robotic arms

This is the most important application. Each joint of a robotic arm, from welding robots and painting robots to pick-and-place robots, uses servo motors to achieve high repeatability and precision.

In Arduino – DIY projects

Mini servos (SG90, MG996R) are the top choice for simple robot projects, model aircraft, or mechanisms requiring open/close angle control using Arduino or other microcontrollers.

Servo Motor Control (Technical Guide)

Controlling a servo requires precise interaction between the central controller and the servo driver.

Controlling a servo using PWM

PWM (Pulse Width Modulation) control is the most common method for mini servos (such as SG90).

- Principle: The servo angle is determined by the width of the square pulse (typical period is 20 ms).

- 1.5 ms pulse: Center position (90°).

- 1.0 ms pulse: 0° position.

- 2.0 ms pulse: 180° position.

Controlling AC servos

Industrial AC servos are usually controlled through more advanced methods:

- Pulse & Direction: The controller (PLC/CNC) generates a pulse train to define the number of revolutions and a direction signal to define rotation direction.

- Industrial communication (Fieldbus): Uses protocols such as EtherCAT, Profinet, CANopen. This method allows fast, versatile data transfer (position, speed, torque) and synchronization of multiple axes at once.

Controlling servos using PLCs

PLCs use high-speed pulse output modules or axis control modules to send Pulse/Direction commands or Fieldbus commands to the servo driver.

Controlling servos using Arduino

Arduino controlling SG90 servo

Use Arduino PWM pins (pins 3, 5, 6, 9, 10, 11) to generate control signals.

Programming with the Servo library

The Servo.h library in Arduino is the most basic tool:

- Declare and attach the pin:

Servo myServo; myServo.attach(9); - Control the angle:

myServo.write(angle);(whereangleis between 0 and 180 degrees).

Servo motor wiring

How to wire

A standard servo system includes:

- Driver: Receives main power (AC/DC) and control commands from the controller.

- Power cable: Connects main power from the driver to the motor stator.

- Signal/encoder cable: Connects the motor encoder to the feedback port on the driver.

Power cable – signal cable – encoder cable

- Power cable: Load-carrying cable that transmits high power (often 3-phase for AC servos).

- Encoder cable: Shielded cable that transmits high-speed digital or analog pulses for position feedback. This is the most important cable to ensure closed-loop accuracy.

Direction reversal, speed settings, position settings

All these parameters are configured in the servo driver through the manufacturer’s dedicated software or via PLC/controller registers. This includes setting gear ratios, torque limits, speed limits, and PID control loops.

Servo Drivers & Accessories

What is a servo driver?

Servo Driver (Servo Drive / Servo Amplifier) is a power electronic device that acts as the bridge between the central controller and the servo motor.

Main functions:

- Power supply: Provides regulated current to the motor.

- Controller: Receives desired position/speed signals, compares them with encoder feedback, and calculates the error.

- Amplifier: Converts control signals into high-power current supplied to the motor.

How to choose a servo driver

You must always select a driver compatible with the motor. Key criteria:

- Rated power: Must match or be greater than the motor power.

- Voltage: Must match both the power supply and the motor.

- Communication: Must support the communication protocol used by your controller (PLC/CNC) (Pulse, EtherCAT, Profinet, etc.).

- Encoder compatibility: Must support the motor’s encoder type (Incremental, Absolute, Resolver, etc.).

Drivers from major brands (Delta, Mitsubishi, Panasonic…)

Leading brands such as Delta, Mitsubishi, Panasonic, Yaskawa, Rockwell Automation, and Siemens all have their own servo driver product lines that are optimized for their motors.

Gearboxes – couplings – cables – encoders

These are essential mechanical and electrical accessories:

- Gearbox: Used to increase torque for heavy loads.

- Coupling: Connects the motor shaft to the load, compensating for small misalignments.

- Cables: Use high-quality, shielded cables, especially for encoder connections.

Using VFDs to drive servos – should you?

You should not replace a servo driver with a VFD (Variable Frequency Drive), except in very specific cases (Vector Control VFD for open-loop servo motors, which still cannot achieve closed-loop servo accuracy). VFDs are designed to control the speed of standard AC motors and do not have built-in encoder feedback ports for closed-loop position control.

Three-phase transformers for servos

In large systems, three-phase transformers are used to convert grid voltage to the levels required by drivers and motors.

Common Servo Motor Faults & Troubleshooting

Understanding and troubleshooting faults helps keep the system running reliably.

Servo overheating

- Causes: Continuous overload, excessively high duty cycle, non-optimized PID parameters, or driver supplying too much current.

- Solutions: Reduce load, check cooling fans, optimize PID parameters, ensure proper heat dissipation for the driver.

Servo vibration

- Causes: Unbalanced installation, loose couplings, encoder faults, or excessively high PID control loop gain (P-gain).

- Solutions: Tighten couplings, realign mechanics, reduce P-gain, run the driver’s Auto-Tuning function.

Servo jerking/oscillation

- Causes: Incorrect control loop parameters, especially integral (I) and derivative (D) values too high or too low.

- Solutions: Retune PID parameters, check mechanical rigidity.

Servo noise

- Causes: Bearing damage, mechanical friction, or electromagnetic noise from the driver (often high-frequency noise).

- Solutions: Replace bearings, check lubrication, adjust driver carrier frequency (if available).

Pre-start servo checks

- Mechanical check: Ensure the motor is firmly mounted, balanced, and couplings are aligned.

- Electrical check: Verify supply voltage to the driver and ensure encoder/power cable connections are secure.

- Software check: Run the JOG function at low speed to confirm rotation direction and stability.

How to Select the Right Servo Motor

Servo selection must be based on a thorough analysis of load requirements.

Based on load

- Inertia analysis: Calculate load inertia. The ratio of load inertia to motor rotor inertia should typically be within 1:1 to 10:1 (depending on application).

- Required torque: Determine the torque needed to hold the load, accelerate, and run continuously.

Based on speed – torque

Choose a motor with a speed–torque curve that can provide sufficient peak torque during acceleration and continuous torque during operation.

Based on power (200W – 400W – 750W – >1kW)

Select a power rating 10–20% higher than the estimated load to ensure performance and service life. Higher power should be prioritized for applications with high acceleration and heavy loads.

Based on brand (Delta, ABB, Panasonic A5…)

- Premium brands: Rockwell, Siemens, Mitsubishi, Yaskawa, Panasonic (high durability, high accuracy, strong technical support).

- Mid-range brands: Delta, Schneider, etc. (reasonable price, stable performance).

Based on the driver in use

If you are building or expanding a system, choose motors from the same brand as your driver/PLC to optimize compatibility and communication (e.g., Siemens PLC should use Siemens servos).

Based on required accuracy

Encoder resolution determines accuracy. Medical equipment and CNC machines require encoders with 18-bit resolution or higher. Standard applications may use 17-bit encoders.

HS Codes for Servo Motors & Controllers

HS code for servo motors

The HS (Harmonized System) code usually falls under Chapter 85 (Electrical machinery and equipment) – heading 8501 (Electric motors).

- Refer to codes such as 8501.52 (AC motors, multi-phase, power > 750W), 8501.32 (DC motors, power > 750W), etc.

HS code for servo drivers

Servo drivers are control devices, usually under heading 8504 (Electrical transformers, static converters) or 8537 (Boards, panels, consoles for control).

- Refer to codes 8504.40 (Static converters), 8537.10 (Boards, panels, consoles, cabinets for electric control and distribution: for voltage not exceeding 1,000 V).

Note: HS codes must be confirmed with customs authorities based on the actual product description.

Top Leading Servo Motor Brands

The current servo motor market is very diverse with many well-known brands, each with its own strengths. Below are some of the world’s leading servo motor brands, along with their key advantages:

- Rockwell Automation (Allen-Bradley): Rockwell Automation is one of the major names in the automation industry. Their servo motors are known for high reliability, stable performance, and easy integration into control systems.

- maxon: maxon specializes in compact servo motors with high precision and large torque. Their products are widely used in applications requiring high accuracy such as robotics, medical devices, and aerospace.

- Mitsubishi: Mitsubishi is a Japanese brand with a long history in automation. Their servo motors are highly durable, user-friendly, and come with many intelligent features.

- Panasonic: Panasonic offers a wide range of servo motor solutions, from standard to high-end product lines. Their products stand out for high performance, stability, and energy efficiency.

- ABB: ABB is a leading global industrial group providing comprehensive automation solutions. ABB servo motors are known for high performance, durability, and adaptability to various working environments.

- Siemens: Siemens is one of the largest automation solution providers in the world. Siemens servo motors are known for high accuracy, stable performance, and easy integration into control systems.

- Schneider Electric: A company specializing in energy management and automation. Schneider Electric servo motors are designed to meet high performance and energy-saving requirements.

Servo Dynamics specializes in supplying servo motors from leading brands such as Rockwell Automation and maxon. We are committed to providing customers with high-quality products, professional services, and optimal solutions for your automation systems.

FAQ – Frequently Asked Questions

What voltage do servo motors use?

- AC servos: Commonly 220V (single-phase or three-phase) and 380V (three-phase).

- DC servos/mini servos: Commonly 5V, 12V, 24V, 48V.

Are servos durable?

Yes, they are very durable. Especially AC servos and BLDC servos, since they do not use brushes; their lifetime mainly depends on bearings and the quality of the driver electronics. With proper maintenance, service life can reach several decades.

Can a servo run continuously?

Yes. Servo motors are designed to operate continuously (24/7) in industrial environments, as long as the required torque does not exceed the motor’s continuous rated torque.

Can a VFD be used to control a servo?

Technically, a standard VFD cannot replace a servo driver. A VFD cannot read encoder feedback for closed-loop position control and therefore cannot achieve the accuracy required of a servo system.

Servo Dynamics Engineering: Authorized Distributor of Rockwell Automation and maxon in Vietnam

Servo Dynamics is the official distributor of leading servo motor brands such as Rockwell Automation and maxon in Vietnam. With more than 17 years of experience, we are committed to delivering:

- Genuine products with high performance and reliability.

- Comprehensive solutions from consulting, design, and installation to system maintenance.

- In-depth technical support from an experienced team of engineers.

If you are looking for an optimal servo solution for your industrial machinery, robots, or medical equipment, do not hesitate to contact us for the best technical advice and support!

Tiếng Việt

Tiếng Việt