Consulting

What is a Harmonic Filter? Working Principles, Construction, and Industrial Applications

The use of power electronic devices such as variable frequency drives (VFDs), UPS systems, and computers is essential. However, a side effect of these devices is the generation of harmonics – a type of “power pollution” that silently damages electrical systems. So, what is a harmonic filter, and how does it solve this problem? This article provides a detailed analysis from theory to practical application.

What is a Harmonic Filter?

Definition of a Harmonic Filter

A harmonic filter is a specialized device installed in an electrical system to eliminate or minimize unwanted current and voltage components that are multiples of the fundamental frequency (50Hz or 60Hz).

The ultimate goal of the filter is to restore the current waveform to a standard sine wave, protecting equipment and improving energy efficiency.

Harmonic Filtering vs. Harmonic Filter

Many people confuse these two concepts:

- Harmonic Filtering: Refers to the solution or technical method (e.g., changing the system structure, using 12-pulse drives, or applying filters).

- Harmonic Filter: Refers to a physical entity, a combination of components (capacitors, reactors, control circuits) manufactured to perform the filtering task.

Why is Harmonic Mitigation Necessary in Industrial Electrical Systems?

Serious Consequences of Harmonics

Harmonics do not just waste energy; they cause direct economic damage:

- Equipment Overheating: Causes copper and iron losses in transformers and motors, leading to fires, explosions, or reduced lifespan.

- Capacitor Bank Failure: High-frequency harmonics reduce the impedance of capacitors, causing massive currents to flow through them, resulting in swelling or explosion.

- Control Interference: Distorts signals from sensors and PLCs, causing circuit breakers (CBs) to trip without an apparent cause.

- Voltage Drops and Distortion: Affects the power quality of neighboring consumers.

Causes of Harmonics (Non-linear Loads)

Energy conversion devices using semiconductor components (IGBTs, Thyristors) are the primary sources:

- Variable Frequency Drives (VFDs): The largest source of 5th and 7th order harmonics in factories.

- UPS Systems: Input rectifiers cause current waveform distortion.

- Office Equipment: Computers, LED lights, and printers (often causing 3rd order harmonics on the neutral wire).

- Arc Furnaces and Welding Machines: Generate large and unstable harmonic amplitudes.

Classification of Modern Harmonic Filters

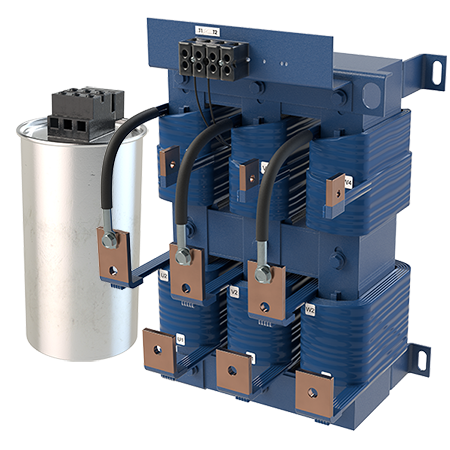

Passive Harmonic Filter (PHF)

This is a classic solution based on the principle of LC resonance.

- Construction: Consists of reactors and capacitors connected in series or parallel.

- Principle: The LC circuit is designed to have extremely low impedance at a specific frequency (e.g., 250Hz for the 5th order). The harmonic current of that order is “trapped” into the filter instead of flowing back to the grid.

- Advantages: Low investment cost, no complex power supply required, high mechanical durability.

- Disadvantages: Can only filter pre-set harmonic orders. Efficiency drops if the load changes. Risks resonance with the power grid, which can cause damage.

Active Harmonic Filter (AHF)

Considered the “pinnacle” of power quality processing technology.

- What is an Active Harmonic Filter? It is a smart power electronic device using IGBT converters and high-speed DSP (Digital Signal Processing) microprocessors.

- Compensation Mechanism: The AHF continuously samples the current, analyzes the distortion components, and immediately injects an opposing current (180° out of phase) to cancel out the harmonics.

- Advantages: Simultaneously filters orders from 2nd to 51st. Filtering efficiency reaches >95%. No resonance risks. Capable of power factor correction (Cosφ) and phase balancing.

Comparison Table: AHF vs. PHF

| Criteria | Passive Filter (PHF) | Active Filter (AHF) |

| Filtering Capability | Specific fixed orders only | All orders (up to 51st) |

| Accuracy | THDi after filtering ~10-15% | THDi after filtering < 5% |

| Load Dependency | Efficiency drops at low loads | High efficiency at all load levels |

| Size | Very large and heavy | Compact, modular design |

| Cost | Cost-effective (Cheap) | High initial investment |

Construction and Connection Diagrams

Components

- For PHF: The core components are the Filtering Reactor (measured in mH) and the Capacitor (measured in kVAR). These must withstand high peak harmonic currents.

- For AHF: Consists of Power Modules (IGBTs), a Central Controller, an HMI display, and high-precision Current Transformers (CTs) for measurement.

Connection Diagram

- Local Filtering: Installed directly at the input of large VFDs. PHF is often used here to save costs.

- Centralized Filtering: Installed at the main busbar of the distribution panel. AHF is typically used to handle the overall harmonics for the entire plant.

Working Principles of Harmonic Filters

Harmonic Cancellation Mechanism

Harmonics are essentially noise signals. The filter works to ensure that at the Point of Common Coupling (PCC), the current remains only at 50Hz.

- PHF: Creates an impedance “black hole” at 250Hz, 350Hz, etc., to trap harmonics.

- AHF: Uses Fast Fourier Transform (FFT) algorithms to separate harmonics in real-time (microseconds) and precisely compensate for the distortion.

Reducing Total Harmonic Distortion (THD)

The THD index represents the level of power pollution. According to the IEEE 519 standard, the Total Demand Distortion (THDi) should be maintained below 5%. A harmonic filter is the only tool that helps businesses meet this standard to avoid utility penalties or power disconnection.

Industrial Applications of Harmonic Filters

- Steel & Cement Industries: Used for smelting furnaces and large grinders to stabilize the internal grid.

- Buildings & Data Centers: AHFs are used to protect sensitive servers and reduce neutral current caused by 3rd order harmonics from office equipment.

- Water Treatment Systems: Protects pump-controlling VFDs, preventing interference with pressure/flow sensor signals.

- Elevators & HVAC Systems: Reduces motor vibration and electromagnetic noise.

Harmonic Filters by Phase Configuration

- 3-Phase 3-Wire Filter: Common in industry, focusing on 5th, 7th, 11th order harmonics…

- 3-Phase 4-Wire Filter: Designed for systems with many 1-phase loads (offices, lighting), helping to eliminate harmonic currents on the neutral wire.

- Selection: If the neutral wire is abnormally hot, you definitely need a 3-phase 4-wire solution.

Popular Harmonic Filter Brands

MTE Harmonic Filters (USA) – Global Quality Standard

MTE Corporation is a world leader in power quality solutions, particularly in high-performance passive filtering technology.

- Matrix® AP (Adaptive Passive) Series: A breakthrough product featuring Adaptive Passive Technology. Unlike standard passive filters that only perform well at 100% load, Matrix AP maintains excellent harmonic filtering efficiency even when the load drops to low levels.

- Key Highlights:

- Guarantees THID (Total Harmonic Induction Distortion) under 5% at rated load.

- Significantly reduces the operating temperature of drives and motors.

- Durable design, easy to install, and virtually maintenance-free.

- Other Products: MTE is also famous for RL/RLW line reactors and dV/dt filters (SineWave Guardian) that protect motor insulation for long cable runs.

Schneider Electric Harmonic Filters

Schneider offers a comprehensive power management ecosystem with high-end active filters.

- AccuSine PCS+/PFV Series: A leading AHF solution capable of handling harmonics, reactive power compensation, and phase balancing simultaneously.

- Advantages: Deep integration into EcoStruxure power management software, enabling remote power quality monitoring and optimization for smart buildings and factories.

Elecnova Harmonic Filters

Elecnova provides flexible and economical active filtering solutions for modern industrial applications.

- Modular Solution: Elecnova AHF filters are often designed in rack-mounted modules, allowing investors to easily expand capacity by adding modules as the load increases.

- Features: Intuitive touchscreen, advanced digital signal processing algorithms for lightning-fast response to non-linear load variations.

Selection and Maintenance of Harmonic Filters

Selection Criteria

- Parameter Measurement: Collect data on THDi, THDv, and Peak Power (Ppeak).

- Filtering Goals: Do you need to reach THDi < 5% or just protect equipment?

- Environment: Temperature and humidity at the installation site.

Installation & Maintenance Notes

- Ventilation: Filters (especially PHFs) generate significant heat; high-capacity ventilation fans are required.

- Periodic Checks: Tighten terminals and measure capacitor capacity every 12 months, as capacitors age over time.

- Compatibility: Do not install an Active Harmonic Filter too close to a capacitor bank without detuned reactors to avoid control loop interference.

Servo Dynamics Engineering: Authorized Distributor of MTE in Vietnam

In Vietnam, Servo Dynamics Engineering is proud to be the authorized distributor and service center for MTE (USA). We don’t just sell equipment; we provide end-to-end solutions:

- Survey & Measurement: Using modern power quality analyzers.

- Simulation: Predicting efficiency after filter installation.

- Technical Support: Experienced engineers consulting on installation and operation.

Contact us today for detailed technical documentation and optimized quotes!

Tiếng Việt

Tiếng Việt