Consulting, News, Solutions

What is a Brushless DC Motor (BLDC)? Difference Between Brushed And Brushless Motors

Brushless DC motors (BLDC) are becoming increasingly popular due to their high efficiency, long lifespan, and stable operation. But how are BLDC motors structured, and how do they work? How do they compare to traditional brushed motors? This article will help you better understand the differences between these two motor types, their advantages and disadvantages, and their practical applications.

What is a Brushless DC Motor (BLDC)?

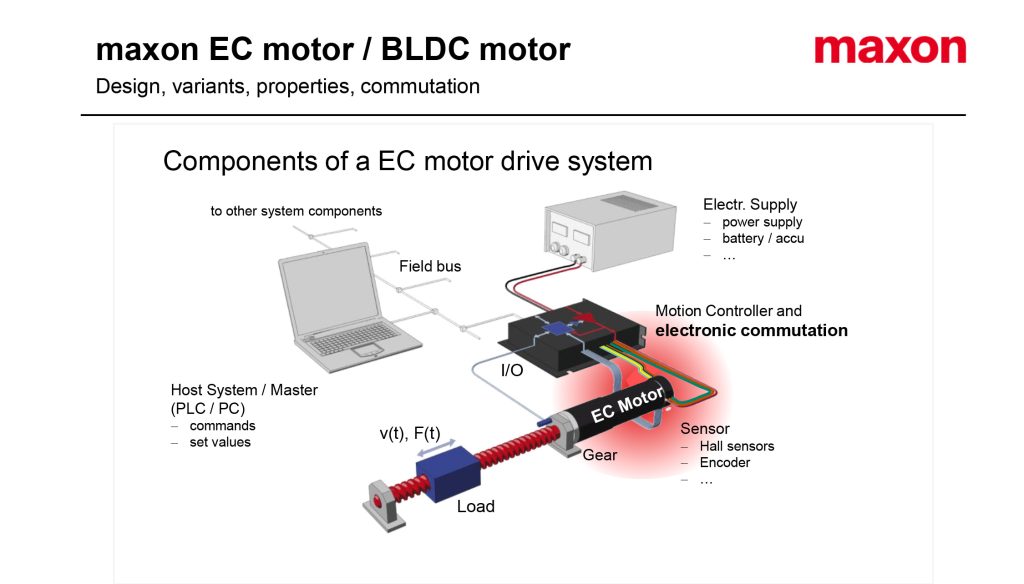

A Brushless DC Motor (BLDC), also known as an EC motor, is an electric motor that uses permanent magnets and an electronic control circuit to generate rotational motion. Unlike traditional DC motors, BLDC motors eliminate brushes and commutators, instead relying on an electronic controller to manage switching. This enhances efficiency, reduces wear and tear, and extends the motor’s lifespan.

Structure of a BLDC Motor

Brushless DC motors (BLDC) are designed with key components that work together to deliver smooth motion and high efficiency. Below are the essential parts:

Stator (Stationary Part):

- Consists of electromagnetic coils wound around a steel core.

- When current flows through these coils, they generate a magnetic field.

Rotor (Rotating Part):

- Contains permanent magnets mounted on the rotating shaft.

- The number and arrangement of these magnets influence the motor’s efficiency and torque.

Electronic Controller:

- Regulates the current flowing into the stator coils, generating a rotating magnetic field.

- Ensures synchronization between the stator’s magnetic field and the rotor, enabling efficient motor operation.

Hall Sensors (Position Sensors):

- Detect the rotor’s position and provide feedback to the electronic controller.

- Help the controller determine the precise timing for switching current through the coils.

Working Principle of BLDC Motor

Brushless DC motors (BLDC) operate based on the interaction between the magnetic fields of the stator and rotor. The electronic controller supplies current to the stator coils in a specific sequence, generating a rotating magnetic field.

This magnetic field acts on the permanent magnets in the rotor, causing it to rotate in a defined direction. The process is continuously maintained through precise control by the electronic controller.

Position sensors play a crucial role in detecting the rotor’s current position and providing feedback to the controller. This allows the controller to adjust the timing of current switching, ensuring stable and efficient motor operation.

Types of BLDC Motors

Brushless DC motors (BLDC) can be classified in various ways depending on the criteria used. Below are some common classification methods:

Classification by Rotor Structure:

- Outrunner BLDC Motor: Permanent magnets are positioned outside, while the stator windings are inside. These motors are typically used in high-torque, low-speed applications such as drones and electric vehicles.

- Inrunner BLDC Motor: Permanent magnets are inside, with stator windings surrounding them. These motors are ideal for high-speed applications like CNC machines and industrial robots.

Classification by Current Waveform:

- Square Wave BLDC Motor: Uses square wave current supply for the windings. It has a simple design and lower cost but may cause vibration and noise.

- Sine Wave BLDC Motor: Uses a sine wave for current control, resulting in smoother operation, lower vibration, and higher efficiency.

Classification by Sensor Type:

- Sensored BLDC Motor: Utilizes Hall sensors or encoders to detect the rotor position, providing precise control, especially at low speeds.

- Sensorless BLDC Motor: Determines rotor position through back electromotive force (back EMF). It has a simpler design but is harder to control at low speeds.

Classification by Number of Phases:

- Single-phase BLDC Motor: Less common and used in specific applications.

- Three-phase BLDC Motor: The most widely used type, offering stable performance and flexible operation.

Advantages and Disadvantages of BLDC Motors

Advantages:

- High Efficiency: Eliminating brush friction reduces energy loss and improves power savings. Efficiency can reach 85-90%, significantly higher than traditional brushed motors (75-80%).

- Long Lifespan: Absence of brushes prevents wear, extending motor lifespan to tens of thousands of hours.

- High Reliability: Fewer mechanical components result in stable operation, even in harsh environments.

- High Rotational Speed: BLDC motors can achieve speeds up to 100,000 RPM, making them suitable for high-speed applications.

- Smooth Operation: The absence of mechanical friction reduces noise and vibration.

- Compact Size: Optimized design makes BLDC motors suitable for space-constrained applications.

Disadvantages:

- High Cost: The complexity of the controller and the use of permanent magnets increase production costs. BLDC motors are more expensive than brushed DC motors.

- Complex Controller Requirement: An electronic control system is necessary for motor operation.

- Technical Knowledge Required: Users need expertise in electronics for proper usage and maintenance.

Applications of BLDC Motors

- Home Appliances: BLDC motors enable smooth, energy-efficient, and durable operation in washing machines, vacuum cleaners, electric fans, and kitchen appliances.

- Electric Vehicles: BLDC motors are used in powertrains, cooling systems, and power steering to enhance efficiency and driving experience.

- Unmanned Aerial Vehicles (Drones): BLDC motors provide powerful thrust, lightweight design, and precise control capabilities.

- Industrial Equipment: BLDC motors are employed in CNC machines, industrial robots, and automated production lines to ensure precise and stable motion.

- Medical Devices: BLDC motors support surgical equipment, electric wheelchairs, and prosthetics with high reliability and flexible control.

- Electronic Devices: BLDC motors are applied in hard drives, printers, and air conditioners to improve durability, reduce noise, and save energy.

Top BLDC Motor Manufacturers

The brushless DC motor (BLDC) market is growing rapidly, with many reputable manufacturers worldwide. Leading brands not only provide high-quality products but also continuously innovate technology to meet the diverse demands of industries such as medical, industrial, electric vehicles, aerospace, and robotics. Below are some notable names along with their countries of origin:

1. Maxon Motor

Maxon is a top-tier Swiss brand known for its high-precision and highly durable BLDC motors. These motors are widely used in industries requiring extreme accuracy, such as medical devices, robotics, and aerospace. Maxon’s BLDC products boast longer lifespans, higher speeds than brushed DC motors, and maintenance-free operation, making them ideal for “install-and-forget” applications.

2. Faulhaber

Faulhaber is one of Germany’s leading BLDC motor manufacturers, specializing in ultra-compact motors suitable for medical devices, precision technology, and applications demanding high performance in limited spaces. Faulhaber’s brushless motor technology ensures smooth operation, energy efficiency, and long lifespan.

3. Nidec Corporation

Nidec is a global leader from Japan in electric motor production, particularly BLDC motors. The company supplies brushless motors for various fields, from home appliances and industrial applications to electric vehicles. With large-scale production capabilities and cutting-edge technology, Nidec leads in developing high-efficiency, energy-saving motor solutions.

4. Johnson Electric

Johnson Electric, a Hong Kong-based brand, specializes in brushless motor solutions for industrial and consumer applications. Its motors are found in electronic devices, HVAC systems (heating, ventilation, air conditioning), and industrial automation solutions, optimizing efficiency and extending equipment lifespan.

5. T-Motor

T-Motor, a renowned Chinese brand, specializes in brushless motors for drones and aerospace applications. Their motors are designed for high performance, lightweight construction, and stable operation under harsh conditions, enhancing flight efficiency and extending drone operation time.

Difference Between Brushed And Brushless Motors

When selecting an electric motor for a specific application, you need to consider Brushed DC Motors and Brushless DC Motors. Each type has its own advantages and disadvantages, affecting performance, lifespan, operating conditions, and costs. Below is a detailed analysis to help you choose the most suitable solution:

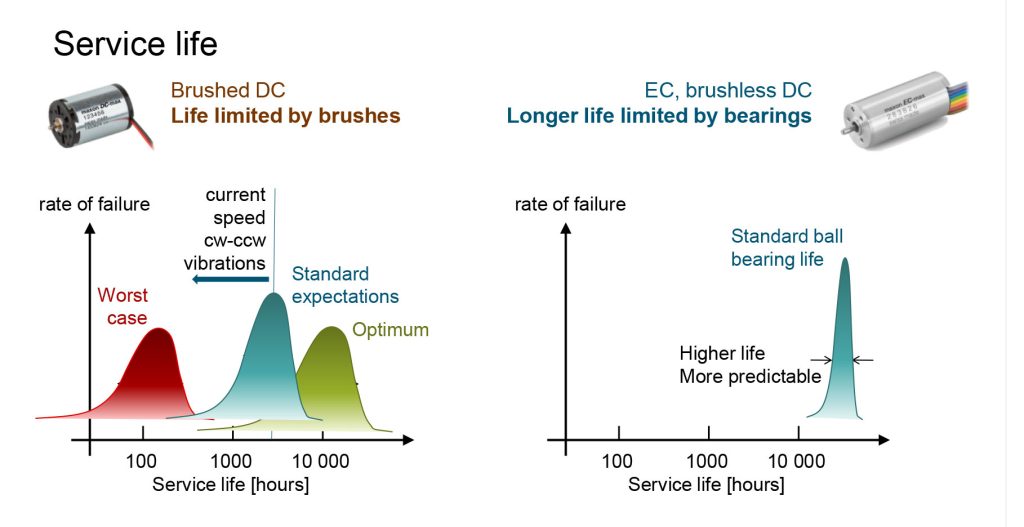

1. Lifespan

- Brushed Motor: Lifespan is limited by brush wear, typically lasting a few thousand hours (up to about 10,000 hours under ideal conditions, but as low as 100 hours in harsh environments).

- Brushless Motor: Significantly longer lifespan as there are no brushes to wear out. The main limiting factor is the bearings, which can last tens of thousands of hours.

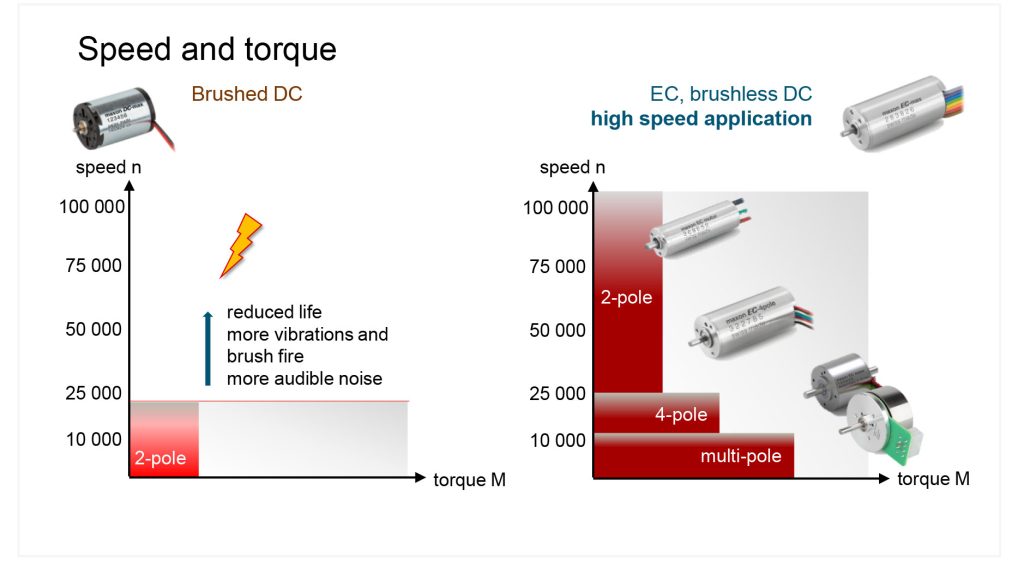

2. Speed and Torque

- Brushed Motor: Usually limited to under 10,000 rpm since high speeds cause brushes to wear out quickly and result in instability.

- Brushless Motor: Can reach very high speeds (up to 100,000 rpm). These motors can also be designed with multiple poles to increase torque, making them suitable for high-torque applications.

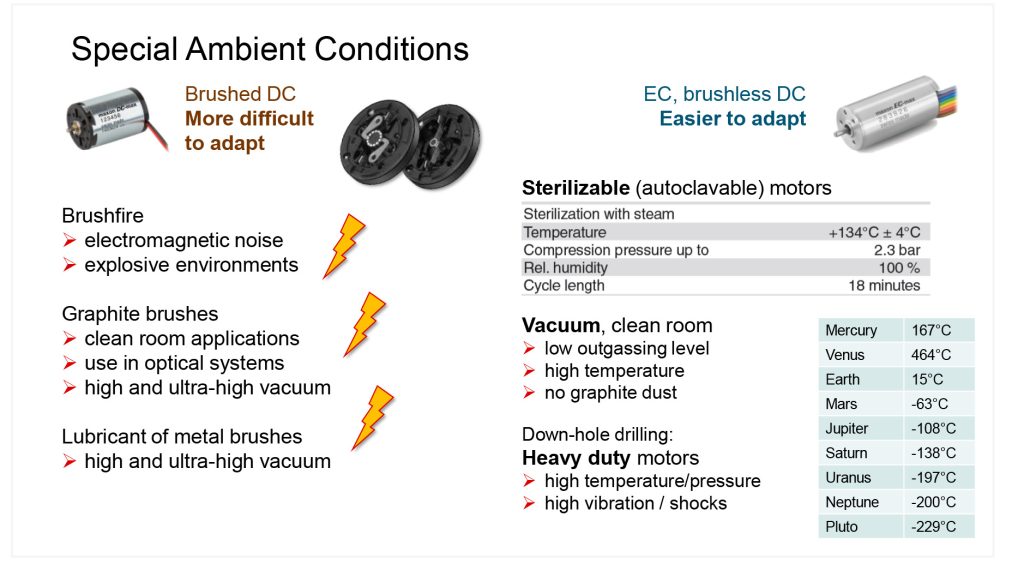

3. Environmental Conditions

Brushed Motor:

- Generates sparks when brushes contact the commutator → Causes electromagnetic interference (EMI).

- Not suitable for environments with flammable gases.

- Graphite brushes can create dust, contaminating clean rooms or optical systems.

- Precious metal brushes require suitable humidity levels and do not perform well in vacuum environments.

Brushless Motor:

- No sparks → More suitable for explosive environments.

- No dust generation → Ideal for clean room, vacuum, or medical applications.

- Easily manufactured in sterilizable, high-temperature, or high-vibration-resistant versions.

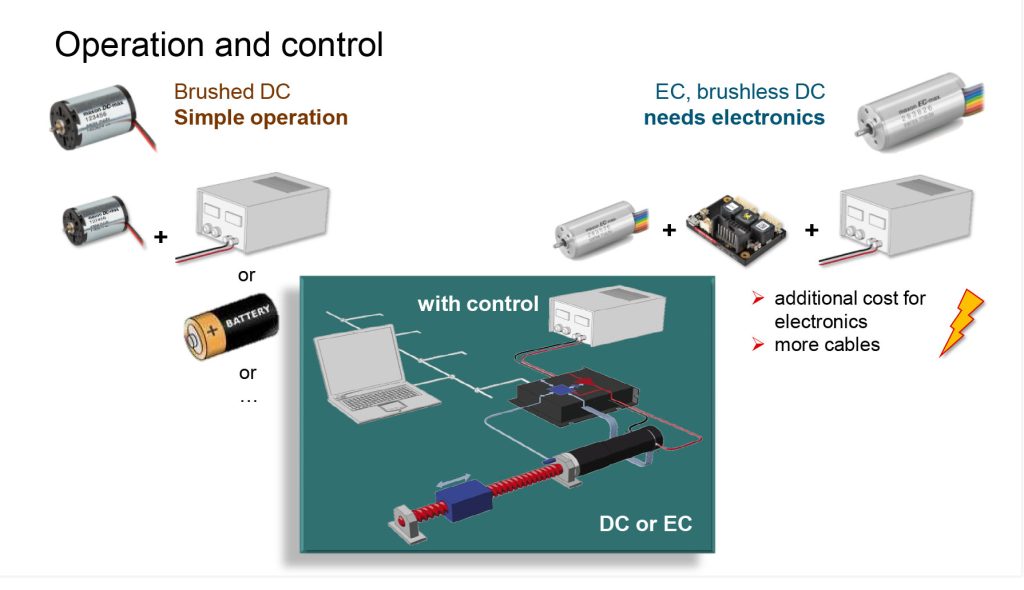

4. Control and Operation

- Brushed Motor: Easy to use, simply apply power to operate.

- Brushless Motor: Requires an electronic controller to switch current through the coils. Wiring and control are more complex (may require up to 8 wires instead of just 2 like brushed motors).

5. Cost and Applications

Brushed Motor:

- Lower cost.

- Suitable for simple applications that do not require long-term maintenance.

- Examples: Toys, fans, small water pumps.

Brushless Motor:

- Higher cost but better efficiency and lifespan.

- Suitable for applications requiring durability and precise control.

- Examples: Robots, electric vehicles, medical equipment, turbines.

Tiếng Việt

Tiếng Việt