Consulting, Industrial Automation

What are IO-Link Signal Tower Lights? Structure, Features, Applications, and How to Choose

Industrial signal tower lights are a familiar sight in every factory. However, with the evolution of industrial automation, an upgraded version has emerged: the IO-Link Signal Tower Light. This device is no longer just an ordinary alert component; it is a critical link in the Industry 4.0 revolution.

This article will delve into the definition, structure, and outstanding benefits of this technology, as well as guide you on how to choose the right IO-Link Signal Tower Lights for your needs.

What are IO-Link Signal Tower Lights? Basic Concepts and Technology

Concept of Industrial Signal Tower Lights (Stack Lights)

- Definition: Signal Tower Lights (or industrial signal tower lights) are visual devices used to display the operational status of machinery and production processes. They provide quick, clear information to operators, maintenance staff, and management about the machine status (running, stopped, awaiting material, or error).

- Structure: They usually consist of multiple tiers (from 1-tier to 5-tier signal tower lights), with each tier having a standardized color (Green: Stable operation, Yellow: Warning/Hold, Red: Stop/Error, Blue, White: Customizable).

What is IO-Link? (IO-Link)

- Definition: IO-Link (IO-Link) is a globally standardized and widespread point-to-point communication protocol in industrial automation. It is considered the standard interface for connecting sensors and actuators at the field level.

- Principle: The key feature of IO-Link is its bidirectional communication. It doesn’t just transmit simple ON/OFF signals; it also allows configuration parameters to be sent down to the device and diagnostic data to be received from the device by the central controller (PLC).

Definition of IO-Link Signal Tower Lights

An IO-Link Signal Tower Light is a modern stack light capable of transmitting digital data completely via the IO-Link standard. The biggest difference is that instead of merely receiving traditional ON/OFF electrical signals, it receives data commands to control color, flashing patterns, brightness, and simultaneously transmits diagnostic data back to the system.

Characteristic Structure and Operating Principle

General Structure and Light Source Type

- Structure: IO-Link Signal Tower Lights have a similar physical structure to standard stack lights, including the pole, colored tier modules, and optionally an audible alarm (buzzer).

- Light Source: Most modern manufacturers use LED signal tower lights to ensure long life, low energy consumption, and excellent brightness.

The Difference in Connection Principles (IO-Link master)

The connection principle of the IO-Link Signal Tower Lights is what makes them innovative:

- Role of the IO-Link master: This is the central device, typically a specialized I/O module, responsible for coordinating and digitally communicating with the signal tower light. The Master supplies power and acts as the data gateway between the light and the PLC/control system.

- The Light as a Device (IO-Link sensor): In an IO-Link network, the signal tower light acts as a smart device (similar to an IO-Link sensor). It not only receives commands but can also send diagnostic data back to the Master.

- Standard Cable and Simplified Wiring: The use of standard, unshielded 3 or 4-wire cables significantly simplifies the wiring process compared to the complex wiring of traditional signal tower lights (e.g., a 3-tier signal tower light).

Outstanding Features and Benefits (IO-Link Signal Tower Lights Advantages)

Bi-directional Data Communication and Error Diagnostics

This is the greatest advantage:

- Diagnostic Capability: The signal tower light can automatically send critical information back to the system, including bulb failure status (LED failure), internal module temperature, or connection errors. This helps the maintenance team perform predictive maintenance instead of reactive repairs.

Flexible and Rapid Configuration

- Remote Control: Color changes, flashing mode, or buzzer sound (signal tower light with buzzer) can be made instantly and directly from the PLC or HMI, without requiring physical intervention on the light.

- Reduced Downtime: When replacing a device, the configuration parameters are stored in the IO-Link master and automatically downloaded to the new device, greatly reducing replacement and setup time (Plug & Play).

Integration with Monitoring Systems (Industrial IoT Lights)

IO-Link Signal Tower Lights are a crucial element, enabling easy data collection and integration into Industrial IoT (Industrial Internet of Things) and MES (Manufacturing Execution System) within smart factories.

Practical Industrial Applications

Precise Machine Status Monitoring

IO-Link Signal Tower Lights are used to display more diverse and precise statuses:

- Operational Status: Running, planned stop.

- Warning: Low material supply, near-term maintenance required (Predictive Maintenance).

- Critical Fault: Emergency machine stop, immediate intervention needed.

Applications in Diverse Fields

This technology is widely applied in:

- Automotive manufacturing and electronics component production.

- Machine tool building and precision machining.

- High-speed packaging systems.

- Automated warehouses and logistics systems (AGVs, conveyors).

Compatibility with Major Systems

IO-Link is an open standard supported by most leading industrial automation solution providers, ensuring high compatibility and interoperability. You can easily find integrated solutions from IO-Link Siemens, IO-Link Beckhoff, or IO-Link ifm.

Guide on How to Choose the Right IO-Link Signal Tower Lights

Selection Criteria by Number of Tiers and Features

- Number of Tiers: Choose the number of tiers (up to 5 tiers) based on the amount of information required for display.

- Features: If a strong alarm is needed, select a signal tower light with buzzer (e.g., a 3-tier signal tower light with buzzer) to provide both audible and visual alerts.

Selection Criteria by Voltage and Environment

- Voltage: IO-Link Signal Tower Lights typically use low voltage (24VDC). However, check the required operating voltage carefully (2-tier signal tower light 12v or 3-tier signal tower light 220v for standard versions) to avoid confusion.

- Environment: Always check the IP Rating (Ingress Protection). For humid or dusty environments, IP65 or higher is required for durability.

Choosing Reputable Brands

Select products from reputable industry brands to ensure quality, durability, and system compatibility:

- Qlight signal tower light

- Patlite signal tower light

- IDEC signal tower light

- Tend signal tower light

Patlite IO-Link Signal Tower Lights: A Leading Solution

Overview of Patlite and its IO-Link Product Line

Patlite is a world-leading Japanese brand, renowned for its high-quality warning and status display devices. Patlite signal tower lights are always at the forefront of adopting new technologies, especially IO-Link.

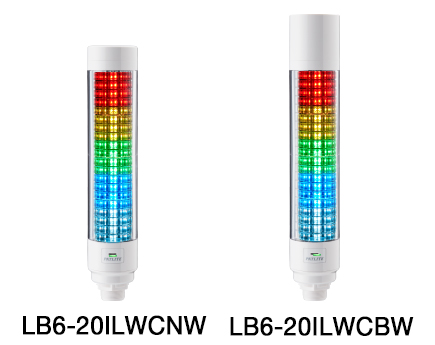

Patlite’s prominent IO-Link models such as the NE-IL and LR-IL series are specifically designed for smart industrial applications.

Superior Features of Patlite IO-Link Signal Tower Lights

- Durability and Standards: Patlite products are known for their high durability and superior resistance to water and dust (IP65 or higher).

- Diverse Features: Wide color range, flexible color customization, and integrated buzzer (signal tower light with buzzer keyword) with various alarm tones.

- High Compatibility: Patlite IO-Link Signal Tower Lights are proven to be highly compatible with most major automation systems and PLCs on the market.

Servo Dynamics Engineering: Authorized Distributor of Patlite in Vietnam

Servo Dynamics Engineering is the official partner and distributor of Patlite IO-Link Signal Tower Lights products in the Vietnamese market. We are committed to providing genuine products with full CO/CQ documentation, along with specialized technical consulting services to help customers select and integrate the most optimal IO-Link solutions for their smart factories.

Tiếng Việt

Tiếng Việt