Hygienic and efficient processes at highest product quality – these are the requirements of the food and beverage industry. We support you in mastering these challenges with reliable sensor solutions.

- Accurate measuring value

- Fast response time

- High temperature stability

Faster response times as well as reliable and accurate measuring values help you optimize your processes and thus save energy, time and media.

- Robust and durable

- Certified for food safety

- Long-term industry know-how

Developed from food industry practice with highest requirements on robustness, hygiene, vibration, temperature and tightness, our sensors allow for 24/7 reliable operation. Safety that pays off.

- Smart sensor solutions

- Perfect-match portfolio

- Easy in engineering and application

Smart sensor solutions reduce complexity and make your plants faster and more flexible. Convincing technology that already today meets the requirements of the digital future.

At home in your industry

The demanding hygienic requirements of milk processing are the traditional basis of our product development.

Brewery

We support the entire production from silo, hot and cold block on to packaging department with our robust sensors.

Beverage production

Quickly changes to the next product when producing a variety of soft drinks and sodas require flexible sensor solutions.

Smart sensor solutions for your applications

CIP – Cleaning in place

Tailored sensor solutions help you solve your cleaning tasks. Perfectly automated to save time, energy, detergents, and water, without jeopardizing food and process safety.

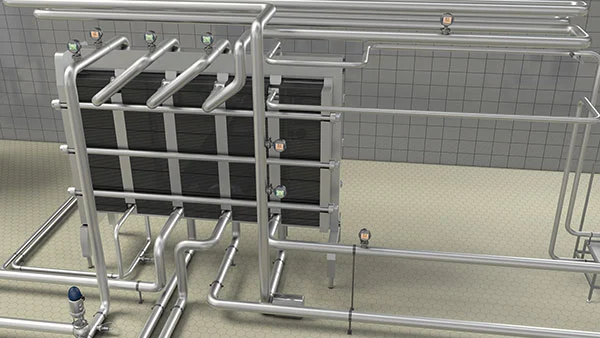

Heat Exchanger

Fast measuring technology, accurate and unaffected by process temperatures, help you optimize energy consumption and cleaning regime while ensuring safe production.

Inventory Management

Reliable sensors allow accurate production planning based on real time values and ensure complete material utilization emptying tanks and silos. Safe batch separation improves production quality.

Certificates and approvals

Certified to comply with the food industry requirements

- Baumer sensors are certified in compliance to all international industry-relevant standards in terms of design and material.

- Baumer processes are certified in line with DIN ISO 9000.

Hygienic design and protection classes

- Hygienic sensors compliant to the directives 3A and EHEDG in terms of design, development and assembly.

- The process from development to series production comes under continuous verification of the application at the customers.

- Sensor protection is center stage and goes beyond IP 69 requirements thanks to proTect+ feature tests.

Smart solutions for maximum process reliability

Ever-growing demands of customer requirements raise the complexity of food production. Smart sensor solutions help you master these challenges and make your processes ready for the future. Our sensors meet the high hygienic requirements of the food industry. To us, absolute process reliability and the premium quality of your products are first. Our cross-technology housing and operation concepts allow you for easy and convenient on-site process monitoring.

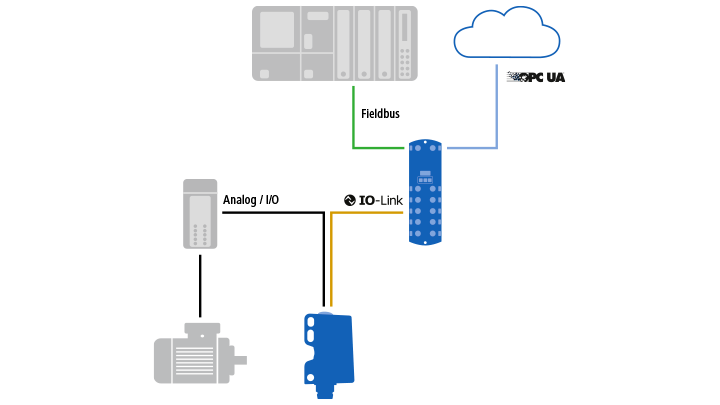

Bridge into a digital future – IO-Link Dual Channel

The term “IO-Link dual channel” was coined by Baumer and refers to sensors that have additional switching or analog outputs alongside the IO-Link communication.

Thanks to IO-Link dual channel, it is possible to operate very fast processes or existing analog interfaces and at the same time enjoy the benefits of IO-Link technology (e.g. parameterization, condition monitoring, etc.).

Baumer CombiSeries®

- Quick set up and easy process monitoring

- Simple touch screen operation

- Alarm warnings by changing color- and value indication on the display

- Flexible display configuration

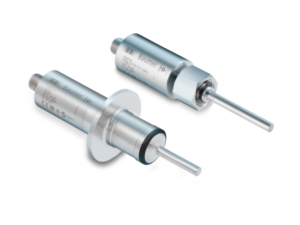

Baumer Hygienic Connection (BHC)

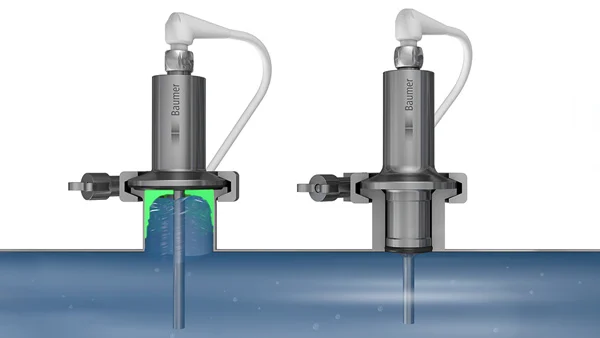

- Flush mounted installation of sensors avoids low velocity areas, supports quick phase shifts, small mixing phases and efficient cleaning

- Robust and simple to weld in system

- A single concept for pressure, temperature, point level detection and flow measurement

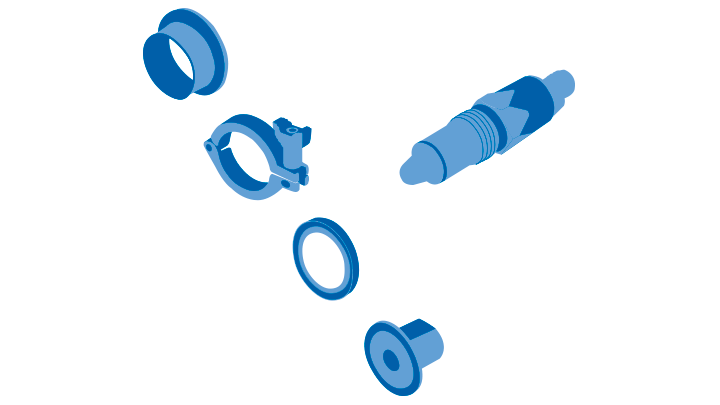

Baumer Connection Identifier (BCID)

The Baumer Connection Identifier helps find your way thru the large variety of process connections, identify the required parts and see how they fit together. The smart adapter concept allows for sensor exchange without changing the process itself. The Baumer Connection Identifier is a comfortable and safe tool to support you in finding the right components.

Portfolio

Tiếng Việt

Tiếng Việt