Patient well-being mandates the highest standards of quality and safety within the pharmaceutical sector. To ensure superior product integrity and provide defense against counterfeiting, Baumer delivers robust industrial cameras and intuitive sensor solutions. These tools are designed for meticulous quality and process control across the entire lifecycle of pharmaceutical goods, from initial manufacturing through packaging and logistics. To suit various needs and environments, available components and accessories offer maximum versatility, including hygienic stainless steel designs with IP 65, IP 67, and IP 69K protection ratings, allowing for the creation of tailored application solutions.

Application

Quality control of blister packs

Keep an eye on your quality

|

With Baumer high-performance industrial cameras and intuitive vision sensors, you can keep an eye on the quality of your blister-packed products at all times.

Applications

Quality control of blister packs

VeriSens vision sensors / Smart Vision solutions

With VeriSens vision sensors, you can check the position and completeness of blistered products and their color simultaneously and with just one image acquisition. Thanks to resolutions of up to 2 megapixels, interchangeable lenses, and an integrated illumination controller, you have full control and can adapt the installation flexibly and cost-effectively to the existing environment. The patented FEX image processor ensures stable and precise inspection even in fast processes for maximum product quality.

Blister pack completeness check

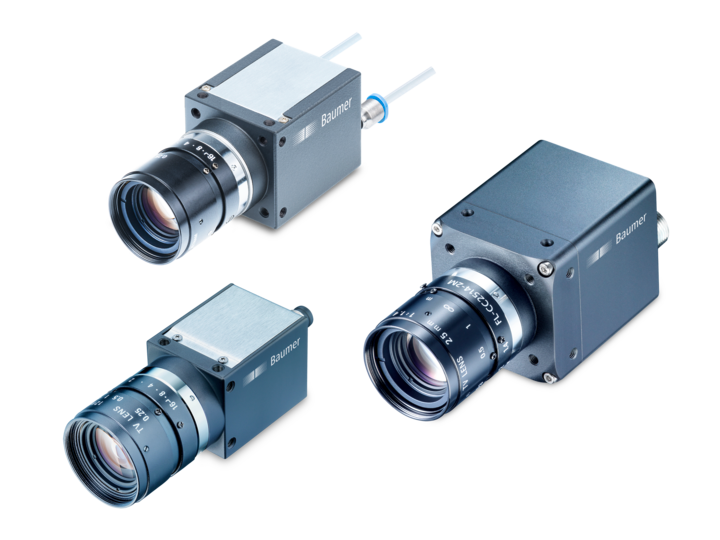

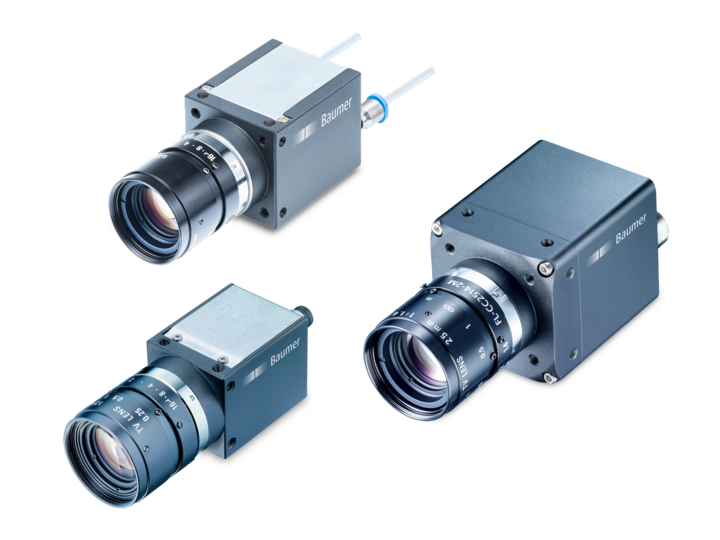

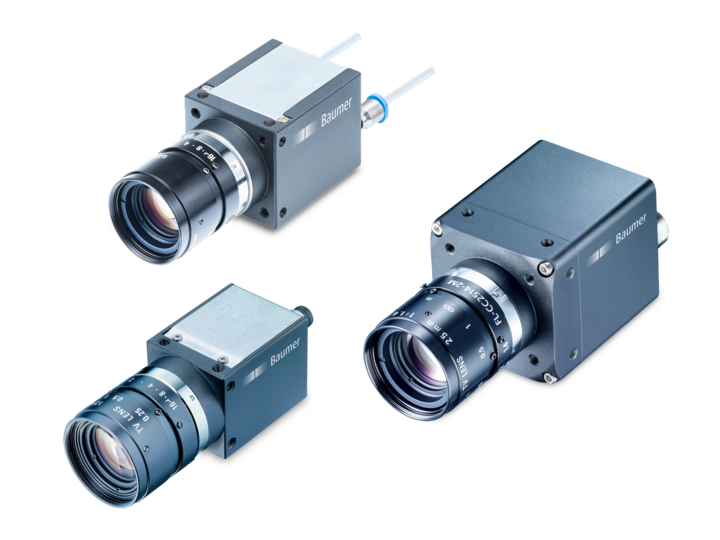

CX cameras

For a reliable completeness check of blister packs, the CX series offers a broad portfolio of monochrome, color, or polarization cameras – so you can always find the right camera for your inspection task. Global shutter cameras with resolutions of up to 12 megapixels and high transfer rates allow precise and fast control even of large areas. The compact 29 × 29 mm CX cameras can be easily and quickly integrated thanks to standard-compliant interfaces, such as GigE Vision, with a cable length of up to 100 m, or USB3 Vision.

Products:

VeriSens vision sensors

Smart Vision Sensors

- Image-based quality control with a single sensor incl. text and code reading

- Automatic object alignment

- 23 powerful feature checks for various inspection tasks

- Configured within a few minutes thanks to VeriSens Application Suite

- Digital inputs and outputs as well as Industrial Ethernet

Inspection of vials, injection, and infusion bottles

Keep an eye on your quality

|

Vials, injection or infusion bottles must meet the requirements of the producers 100%. Baumer will support you in this area with powerful industrial cameras for your various quality controls.

Applications

Seal inspection of stoppers, caps and crimps

CX cameras

With the fast CMOS cameras of the CX series, you can reliably check seals for deformations, defects, correct seating and product mixes, such as incorrect shapes and colors, even at high speeds. Flexible machine integration is a reality with the all-round M3 mounting and the compact housing of only 29 × 29 mm. The CX.I cameras also offer four power outputs of up to 120 W (max. 48 V / 2.5 A) for direct lighting control without an external controller. This further simplifies integration and reduces system costs.

Quality inspection of containers

CX cameras, LX cameras

The reliable inspection of containers to find particles, dirt accumulation, cracks, deformations or defects on the bottle body requires high image quality and resolution at simultaneously high production speeds. The cameras of the CX series, with the latest CMOS Global Shutter image sensors with up to 12 megapixel resolution, functions such as Burst Mode for fast continuous shooting and short exposure times from 1 µs, are particularly suitable for this. Thanks to the integrated sequencer, image acquisition parameters such as exposure time, region of interest (ROI), or outputs for illumination control can be switched quickly, even at very high speeds.

To detect even very fine details such as suspended particles, the LX series of cameras offers resolutions of up to 65 megapixels.

Filling level monitoring

CX cameras

Depending on the product format, filling level monitoring for underfill and overfill detection can be combined with other inspections, such as seal inspection or quality control. The CX series cameras offer different sensor formats and resolutions of up to 20 megapixels to perform the inspections with just one camera, creating system cost savings.

Products:

High-resolution, fast, and robust CMOS cameras

Industrial cameras

- Up to 65 MP and 1622 fps

- Sony Pregius, Sony Pregius S, Gpixel GMAX, onsemi PYTHON, ams CMV

- Global shutter sensors

- GigE Vision, 10 GigE Vision, Camera Link

- 60 × 60 mm

Product tracking with Track & Trace

Keep an eye on your quality

|

Complete traceability along the entire production and supply chain increases the safety of pharmaceutical products. Baumer can support you here with powerful industrial cameras and versatile vision sensors.

Applications

Reading and verifying product labels

CX cameras, VeriSens vision sensors

In order to reliably check the label content and print quality of 1D and 2D codes as well as text, even at high cycle rates of up to 40,000 pieces per hour, Baumer offers a wide range of fast CMOS cameras with resolutions of up to 20 megapixels and VeriSens vision sensors for different product sizes. Models with a dynamic range of more than 70 dB or polarization cameras are available for tests on reflective surfaces. Together with the Baumer GAPI SDK (Software Development Kit), reliable image transmission with an exact time assignment to the recorded product (trigger ID) is ensured.

Reading bulk codes (multi-code reading)

CX cameras, LX cameras

During serialization and aggregation in the packaging process, several product labels must be verified simultaneously. High-resolution rolling shutter CX cameras with up to 20 megapixels allow cost-effective implementation.

If verification is consistently in motion, or if higher resolutions are required, the LX series global shutter cameras with resolutions of 20, 25, 48, or 65 megapixels are ideal. All Baumer GigE Vision-compliant cameras feature Power over Ethernet (PoE) for easy integration with a single cable solution.

Products:

High-resolution, fast and robust CMOS cameras

Industrial cameras

- Up to 65 MP and 1622 fps

- Sony Pregius, Sony Pregius S, Gpixel GMAX, onsemi PYTHON, ams CMV

- Global shutter sensors

- GigE Vision, 10 GigE Vision, Camera Link

- 60 × 60 mm

VeriSens vision sensors

Smart Vision Sensors

- Image-based quality control with a single sensor incl. text and code reading

- Automatic object alignment

- 23 powerful feature checks for various inspection tasks

- Configured within a few minutes thanks to VeriSens Application Suite

- Digital inputs and outputs as well as Industrial Ethernet

Explore Baumer Products

Learn more

About Baumer An international family-owned business with a passion for sensor technology, encoders, measuring instruments [...]

Everything is packaged, from consumer goods to food and pharmaceutical products. The Baumer Group has [...]

Together, we can guarantee food safety, availability and production planning capability for your business. Enhancing [...]

Tiếng Việt

Tiếng Việt