Industrial Automation

Sensors

Industrial Equipment

Motors & Motion Control

100% Genuine & Brand New Products

Official Manufacturer Warranty

Guaranteed Authenticity

After-Sales Service Support by Servo Dynamics

Fast Delivery Support on the Same Day*

*For all in-stock products

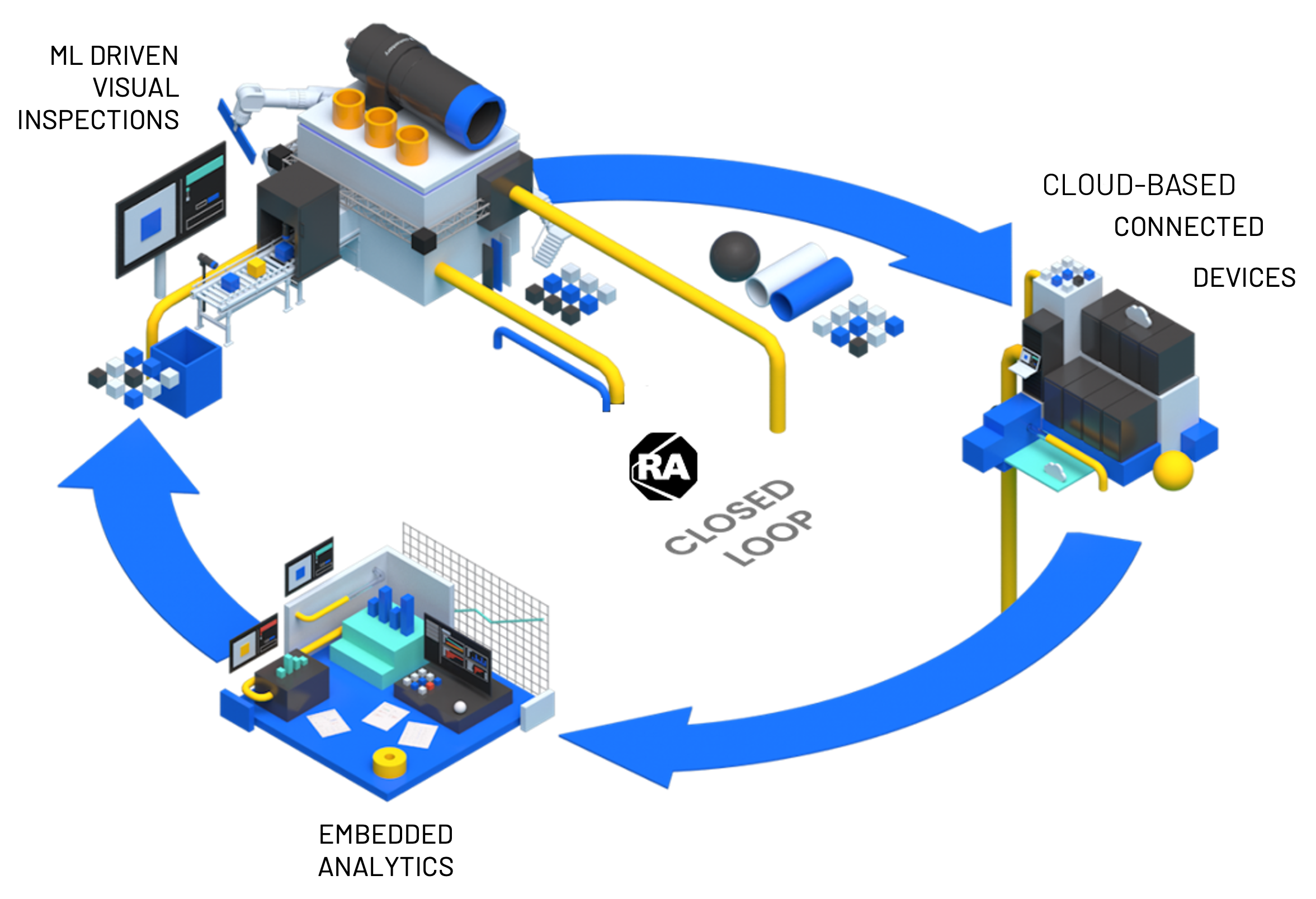

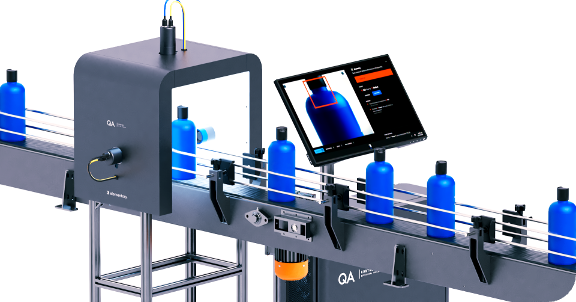

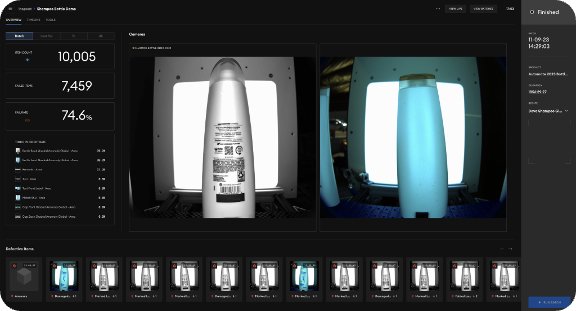

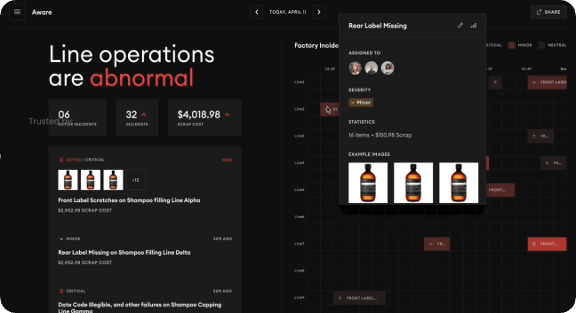

FactoryTalk® Analytics™ VisionAI™ takes a no-code approach to vision inspection to improve quality, maximize yield, and gain critical insight from real-time production data.

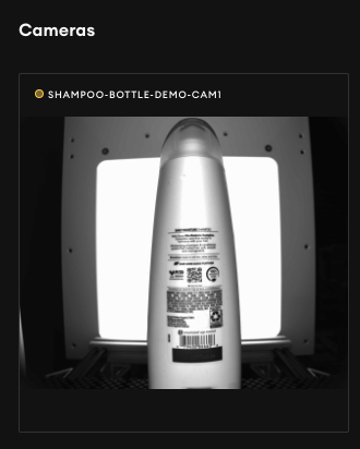

Throughout the entire user workflow (from camera configuration and capturing images to training and deploying models, and even for analyzing quality performance), our machine learning and vision inspection solution helps quality personnel and plant operators view the information they need to achieve their quality performance targets.

FactoryTalk Analytics VisionAI finds defects, previously impossible to detect, driving insights and actions.

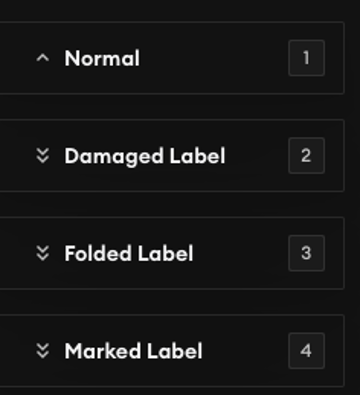

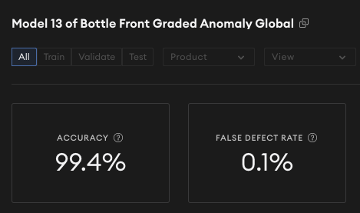

Train a specialized AI model for your product with FactoryTalk Analytics VisionAI, delivering a lightweight yet highly effective solution for detecting even the subtlest and rarest anomalies in production.

Go beyond simple pass/fail judgments with the Rockwell Automation cloud-based platform, offering detailed anomaly analysis and enabling corrective actions.

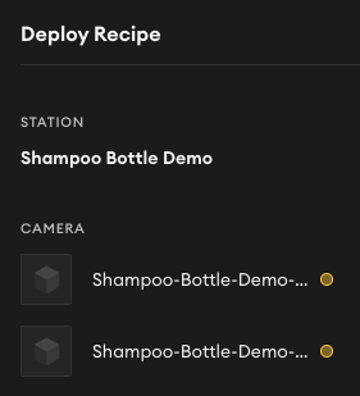

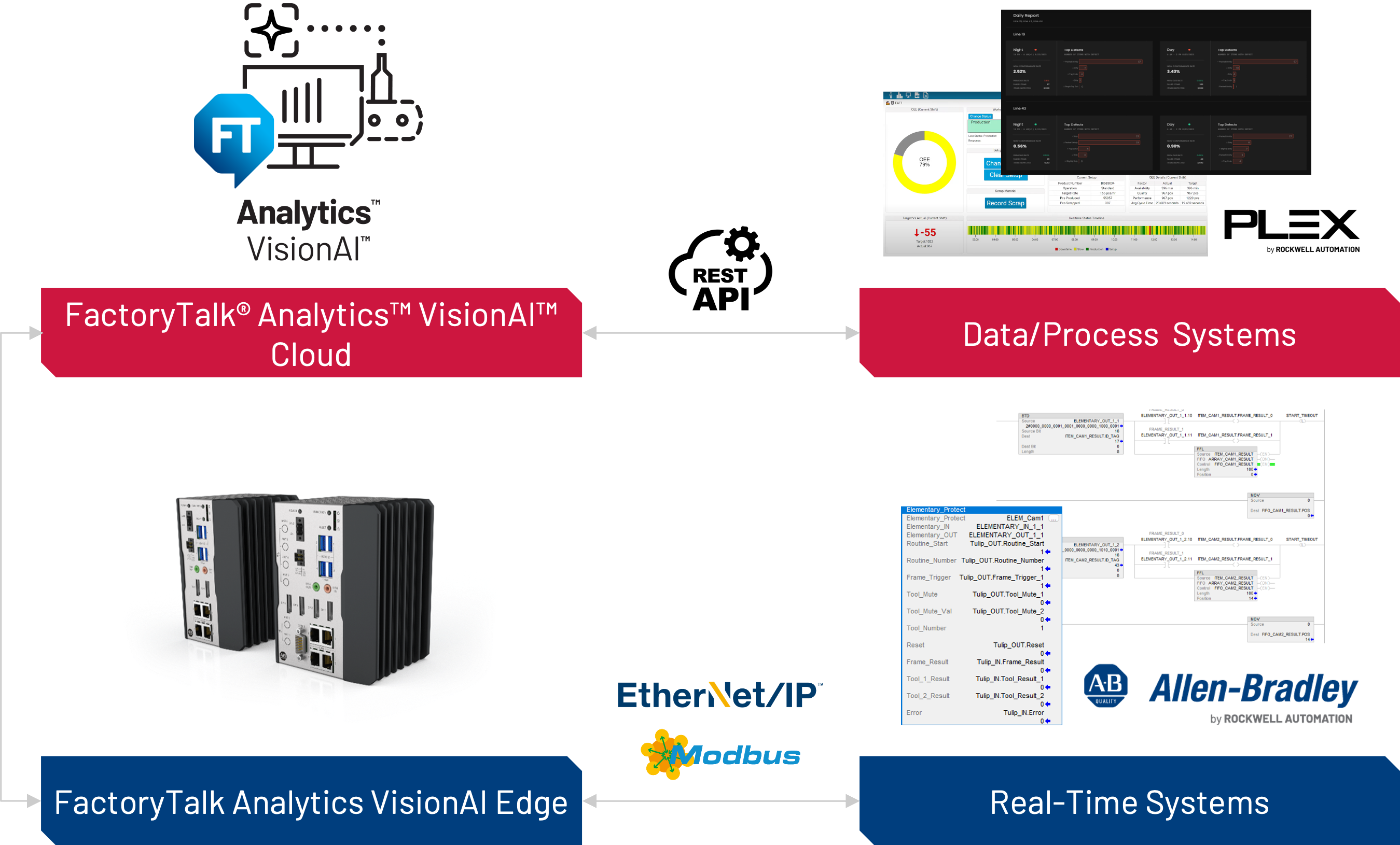

Once we’ve detected your defects, the results of your quality inspection can be shared at the edge with control systems and in the cloud via API to your MES/QMS.

Artificial intelligence (AI), machine learning, and model management in the cloud to deliver unparalleled, advanced quality inspection

Rockwell Automation combines hardware, software, and domain expertise to simplify quality inspection

Our end-to-end FactoryTalk Analytics VisionAl workflow enables manufacturers to easily deploy machine learning models across their facilities. Model development relies on production experience and a clear understanding of what good and bad quality products look like, reducing the need for machine vision expertise to create or update models. Once models are deployed, the AI in VisionAI brings a more intuitive analysis of images, allowing for a human-like interpretation of the product during the inspection process.

Rockwell Automation provides an integrated solution, simplifying installation and shortening the time value

Select at least 2 products

to compare