Solutions, Consulting, Events, News

Filling and dosing systems / Bottling plants

Sensor solutions for the entire production and packaging process

The Baumer Group meets the specific requirements in the production and packaging process with a positive impact on food safety. The packaging process also needs to satisfy the demands for increased machine flexibility and performance. Machine manufacturers preferably implement our solutions with the aim of reducing complexity. In terms of industrial and customer requirements, the configuration of individual machine modules ensures that the part systems link up to create an optimum overall system.

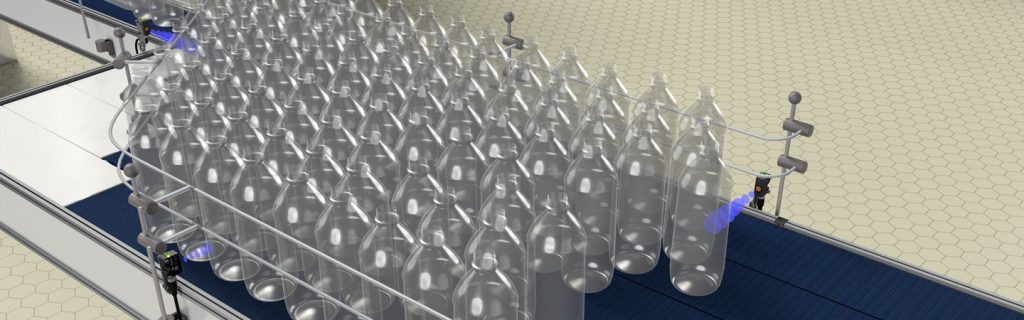

Buffer tables are monitored by sensors in order for modern filling and packaging machines to achieve the greatest possible efficiency. Irrespective of the buffer capacity and container variance, Baumer sensors monitor the no-pressure backup of large quantities over the smallest possible area. This ensures system downtimes are reduced to a minimum.

Benefits of Ultrasonic Proximity Switches

- Reliable Detection and High Variance: Ensures ease of selection and planning, reducing costs.

- Reduced Setup Time: Fast adaptation to different applications by setting the sound beam width (e.g., narrow for individual objects, broad for groups).

- Flexible Parameterization: Adjustable filter functions for an optimum between response time and repeatability.

- Easy Adjustment: Flexible adjustment of switching point with qTeach® or IO-Link.

| Application | Function/Indication |

|---|---|

| Buffer Table Full | Filling is no longer possible |

| Buffer Table Ready | Ready for filling |

| Buffer Table Emptying | Monitoring container flow |

Product Spotlight:

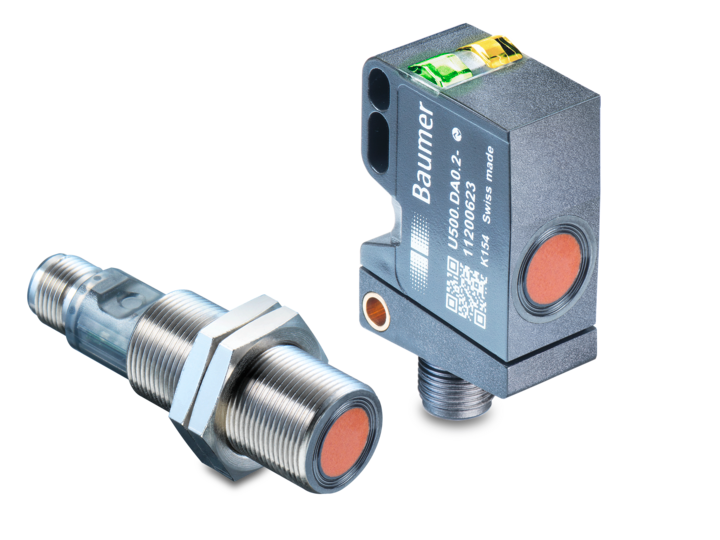

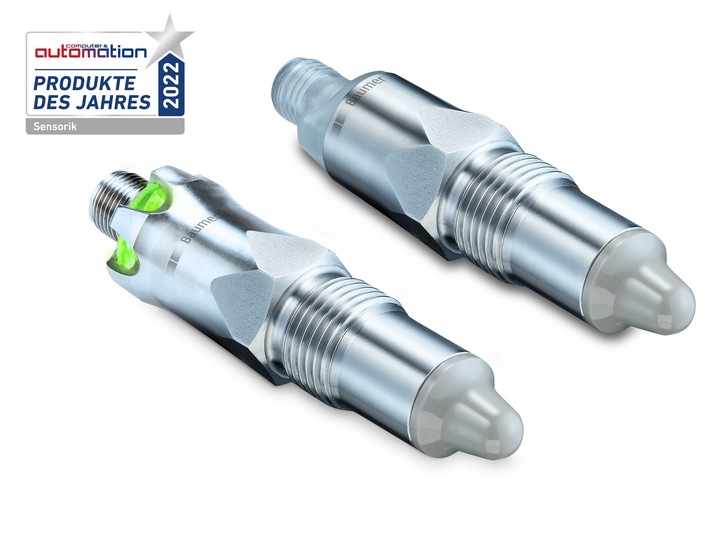

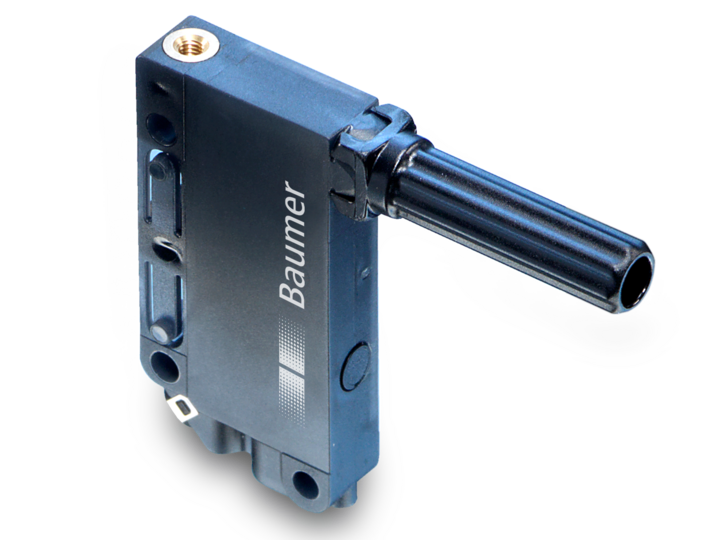

Robust Ultrasonic Sensors

- Sensing Distances: Up to 2000 mm

-

Design: The sensor body is cast in a single solid piece for durability, allowing it to operate in harsh environments. It uses a magnetic-based adjustment principle, providing excellent resistance to water and dust.

-

Connectivity: Built-in IO-Link protocol enables flexible and easy parameterization through software, along with multiple output options: PNP / NPN / Push-Pull.

- Variants: Also available with 2 output switches, as a retro-reflective or through-beam sensor.

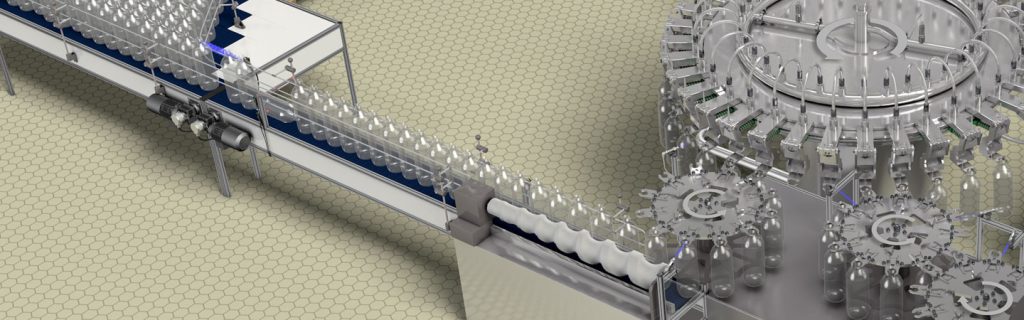

As containers transition from the buffer table to form an orderly line, the sensors monitor their position. A production output rate of more than 110,000 bottles or cans per hour is possible.

1. Container Position Monitoring Solutions

1. SmartReflect Light Barrier (for Transparent Containers):

- Advantages: Reduced production time and costs, as no reflector is necessary.

- Reliability: High operational reliability and imperviousness to soiling due to the barrier principle.

- Versatility: Suitable for objects of different colors, surface finishes, or transparency.

- Range: Extended detection range from 30 mm to 1000 mm.

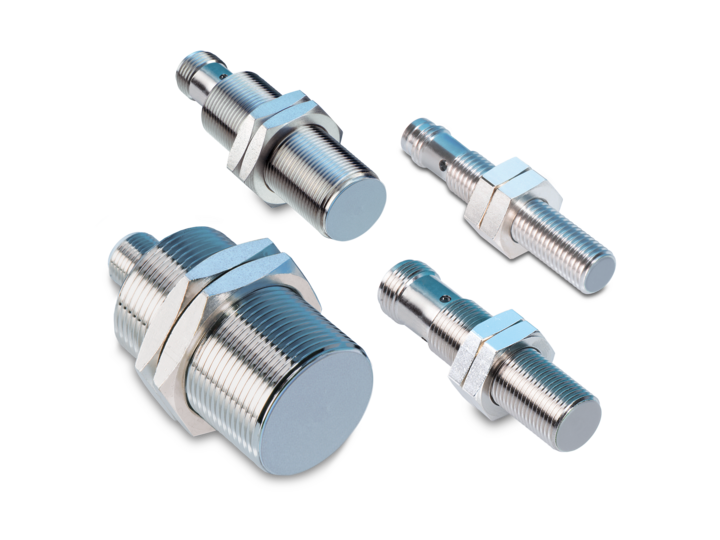

2. Inductive Proximity Switch (for Metal Containers):

- Reliability: High operational reliability, unaffected by background reflections.

- Accuracy: High positioning accuracy with a repeat accuracy of approximately. 10 µm.

- Versatility: Factor 1—one sensor variant for different metal containers.

- Rate: High machine output rates of up to 50 metal containers per second.

3. Diffuse Sensors with Background Suppression:

- Stability: Stable detection process due to immunity to background reflections.

- Performance: High output rate thanks to fast response times and very small light spot.

Product Spotlight:

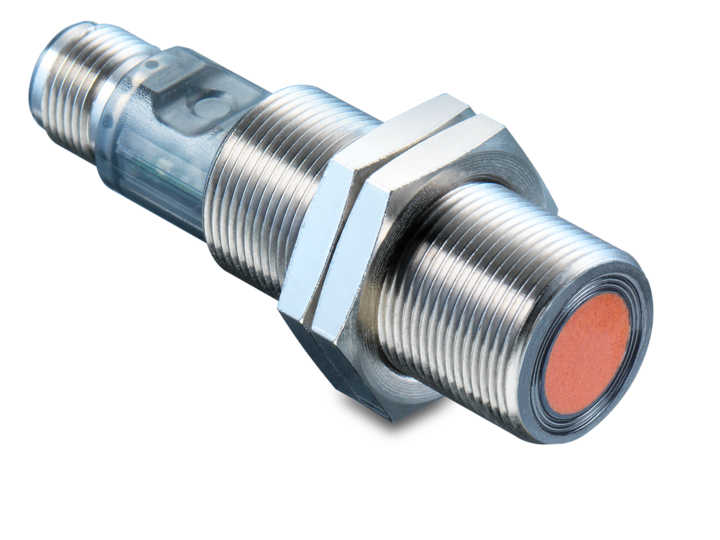

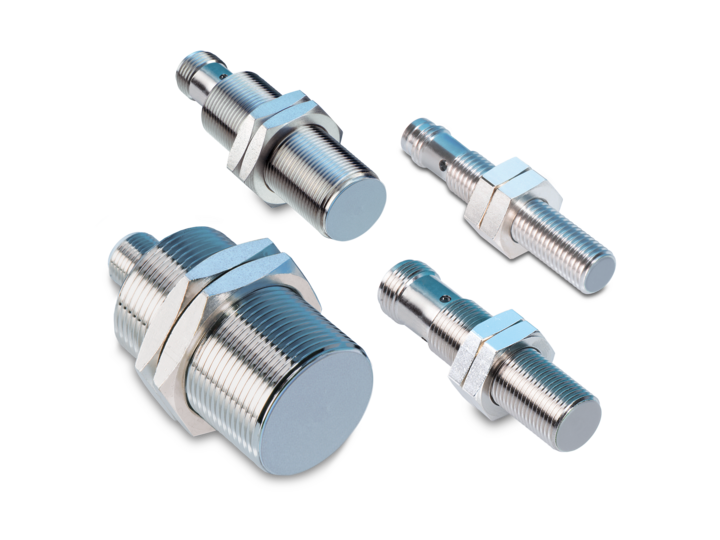

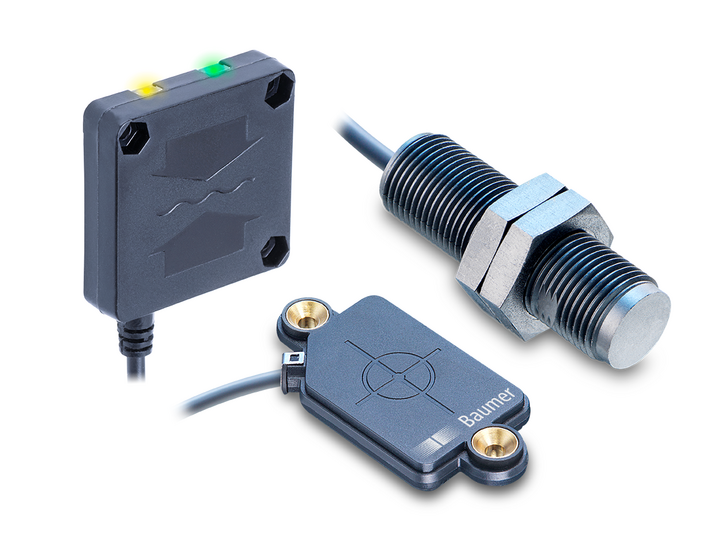

Standard cylindrical sensors

Inductive proximity switches

Miniature sensors

Photoelectric sensors

2. Container Transfer to Capper Monitoring

This phase covers the critical transition of containers through the infeed system and into the high-speed filling and capping areas.

1. Monitoring Container Transfer to Screw Conveyor

The SmartReflect technology is ideal here, especially for detecting transparent containers, as it eliminates the need for a separate reflector.

| Feature | Benefit/Advantage |

| Shorter Start-up Times | Visible light spot ensures fast sensor alignment. No readjustment required thanks to the optically aligned axis (qTarget). |

| Operational Reliability | Uses a reliable barrier principle between sensor and machine part. No reflector necessary (reducing maintenance/cost). |

| High Productivity | Small light spot is suitable for narrow packaging gaps. Impervious to soiling (plastic, stainless steel, or hygiene design). |

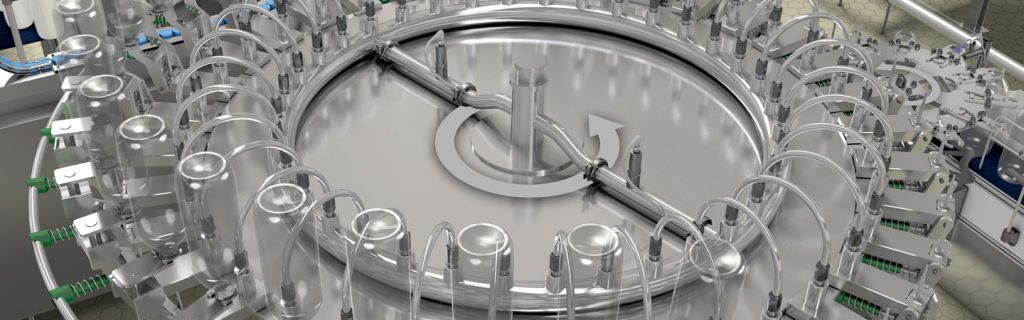

2. Monitoring Container Transfer from Screw Conveyor to Capper

This high-speed transition demands highly reliable sensors, often utilizing ultrasonic technology for maximum variance and speed.

Ultrasonic Retroreflective Barrier (High-Speed Transfer)

| Key Metric | Performance/Advantage |

| Reliability & Variance | Extremely high packaging variance due to ultrasonic principle. High machine availability with function reserves. |

| Performance | High machine productivity with proven output rates up to 110,000 bottles/hour. |

| Speed & Accuracy | High positioning accuracy with a fast 6 ms response time. |

| Maintenance & Costs | No additional reflector necessary; low decision-making costs due to minimum gap between objects. Impervious to aggressive liquids. |

IP 69K Hygienic Sensors (Cleaning/Rinsing Area)

| Key Metric | Performance/Advantage |

| Operational Reliability | Hygiene design for reliable detection in the hygiene zone; aligns rotation-asymmetric containers. |

| Performance/Speed | High machine productivity with a response time of less than 3 ms. |

| Maintenance/Durability | Low maintenance cost and high machine availability. Resistant to cleaning agents (Ecolab tested). |

| Intelligent Functions | Supports localization of measuring range, averaging, maintenance status message, and switching window adjustment. |

Product Spotlight:

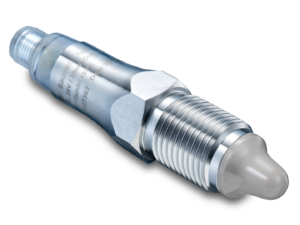

Miniature M12 sensors – chemically robust

Ultrasonic sensors

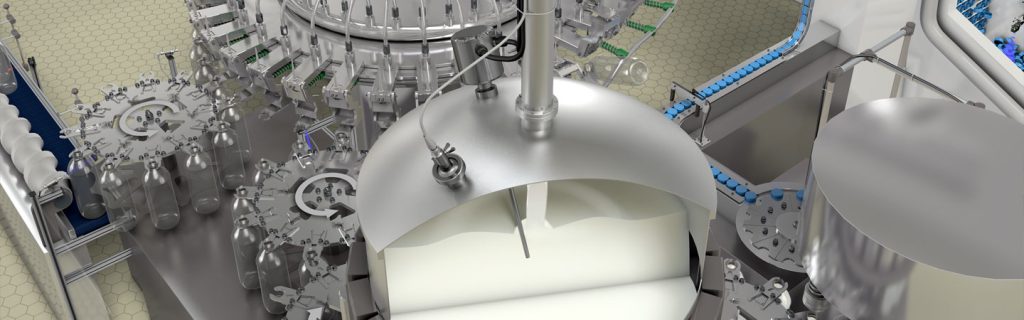

In terms of reusable packaging such as bottles, ensuring high cleaning quality is a first step towards food safety. Measuring the flow rate and temperature in the rinsing process ensures reliable cleaning performance.

A calorimetric measuring principle is used to monitor flow rate and temperature

High process reliability

- Maintaining the defined flow rate and temperature for sterilization

- SIP-capable up to 150 °C, no time limit

- Flow measurement at media temperatures of up to 125 °C

Reduced complexity and installation time

- Parallel measurement of flow rate and temperature

- BHC process connection for all process variables

- Linearized and calibrated output signals

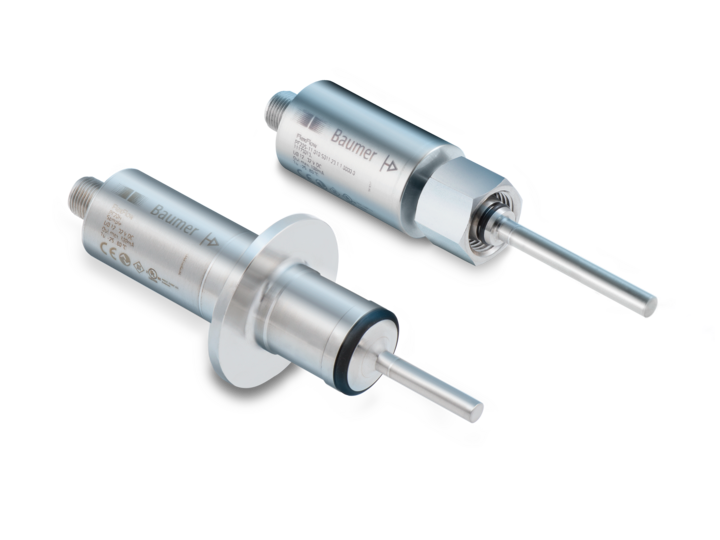

Product Spotlight:

Flow sensors for measuring the flow rate

Flow measurement

Food safety has top priority also when it comes to process monitoring in the machine tank. With hygienic flush process connections, we guarantee outstanding cleanability while at the same time reducing the cleaning time.

1. Monitoring pressure in the machine tank

Piezoresistive pressure measurement for absolute pressure, relative pressure, and vacuum

Reliable design

- Precision and long-term stability for efficient process

- Suitable for demanding processes with frequent temperature fluctuations

- Sturdy sensor element secures machine availability even at peak pressures

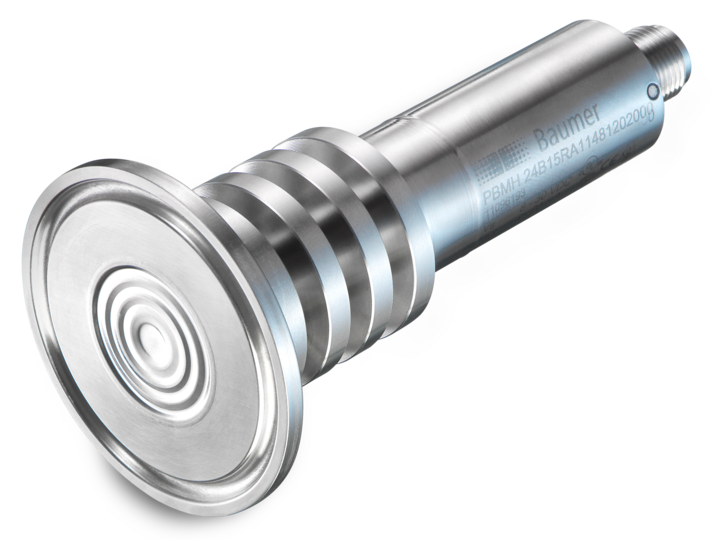

Product Spotlight:

High-precision pressure sensor with flush clamp connection

Pressure measurement

2. Soiling monitoring

Inductive conductivity measurement for monitoring purity

High food safety

- Detection of minimal quantities of residual chemicals for high product quality

- Rapid temperature compensation

- EHEDG and 3-A certified hygiene design

Product Spotlight:

3. Level monitoring

Potentiometric level sensors

Level sensors

Point level sensors CleverLevel®

Point level sensors

Capacitive level sensors

Point level sensors

The demands placed on capping machines in terms of performance and flexibility are ever increasing. We support all types of closures for the most diverse requirements in the pharmaceuticals and cosmetics as well as the food and drink industries. This ensures hygienic standards are achieved, thus allowing these machines to also be used as aseptic cappers.

1. Cap level monitoring in the bin

Level detection over medium distances up to 2 m

Ultrasonic level measurement

2. Trigger sensor in wet and cleaning zone for smart camera

SmartReflect – light barrier with no reflector for detecting caps

Reduced production costs and times

- Visible light spot for easy sensor alignment

- No reflector necessary

High operational reliability

- High machine flexibility as different colors and shapes are reliably detected

- Immunity to background reflections ensures a stable detection process

Low service costs

- Enclosure protection class IP 68/IP 69K and proTect+

- Ecolab certified

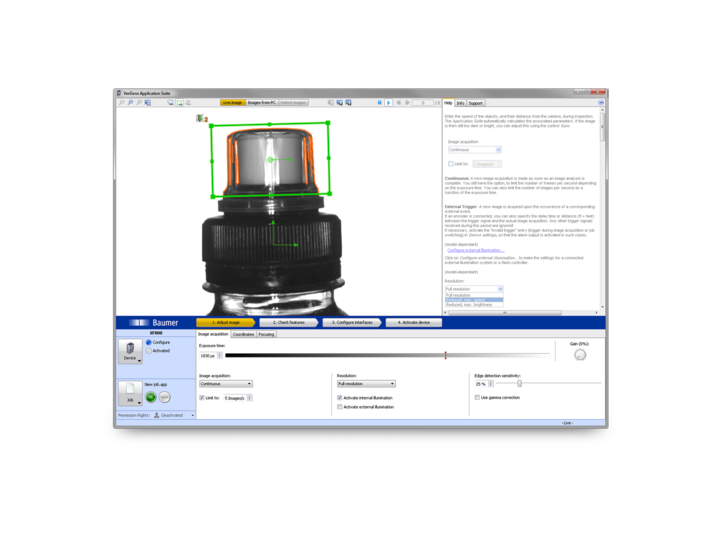

3. Checking screw caps with freshness seal for deformation

Image-based quality control with vision sensors

High production security

- Reliable monitoring of caps with freshness seal with patented FEX® contour detection down to 1/4 pixel accuracy

- Up to 6000 checks/minute

Reduced servicing and startup costs

- Stainless steel enclosure of washdown design and protection class IP 69K (tested at 80 °C and 100 bar pressure)

- User-friendly sensor configuration in four simple steps

Product Spotlight:

Industrial cameras

Industrial cameras / image processing

4. Cap infeed buffer full

Diffuse sensors with background suppression

Reduced production times and costs

- Visible light spot for easy sensor alignment

- No reflector necessary

High machine availability

- Reliable detection of different colors and shapes

- Unaffected by background reflections and extraneous light

Product Spotlight:

Miniature sensors

Photoelectric sensors

Subminiature sensors series 04 / 07 / 08

Photoelectric sensors

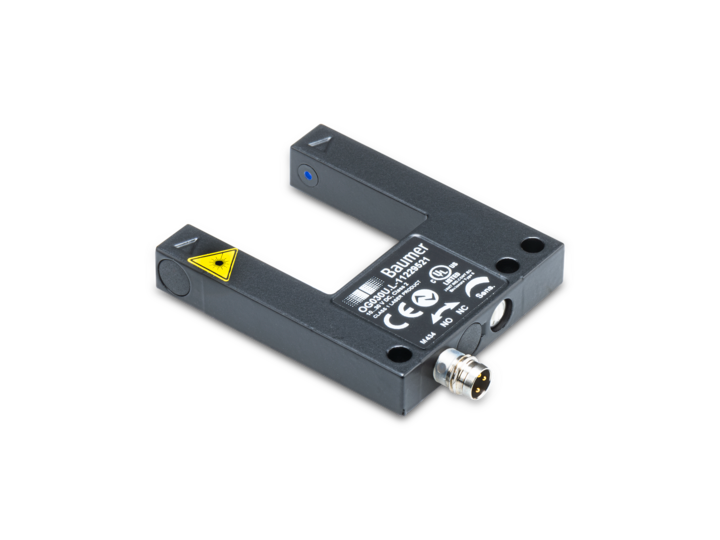

5. Preparing caps for takeup

Laser fork light barrier

Reduced installation and decision-making costs

- No alignment of transceiver necessary

- Fork width from 20 mm to 120 mm

High machine availability

- Through beam principle for secure detection process

- Unaffected by extraneous light < 100 kLux

Product Spotlight:

Subminiature sensors series 04 / 07 / 08

Photoelectric sensors

Fork sensors

Laser photoelectric sensors

With Baumer sensors in the outfeed station you have a wide range of options for checking production quality and display the results online during operation. A large number of features are checked simultaneously. Various customized recipes can of course be stored and called up as required.

Container exiting filling machine

Miniature sensors

Photoelectric sensors

Standard cylindrical sensors

Inductive proximity switches

High quality products also with maximum food safety in different packaging – these consumer requirements greatly influence the production processes and quality control. These factors in turn are used as the requirement profiles for our sensors. With our corresponding technologies we support the required flexibility in the most diverse machine applications.

1. Level monitoring in packaging

Ultrasonic distance sensor with extremely narrow sound beam

High quality assurance

- Linearized measuring range with 0.5 mm repeat accuracy

- Reliable ultrasonic retroreflective barrier principle

Reduced decision-making costs

- Up to 150 mm detection range for a diverse range of media

- Response times of less than 7 ms (measuring)

- Response times of 1.3 ms (switching)

Product Spotlight:

Level measurement into very small containers

Ultrasonic level measurement

2. Trigger sensor for smart camera

Diffuse sensors with background suppression

Reduced production costs and times

- Visible light spot for easy sensor alignment

- No reflector necessary

High operational reliability

- High machine flexibility, as different colors and shapes are reliably detected

- Immunity to background reflections and extraneous light ensures a stable detection process

Product Spotlight:

Miniature sensors

Photoelectric sensors

Subminiature sensors series 04 / 07 / 08

Photoelectric sensors

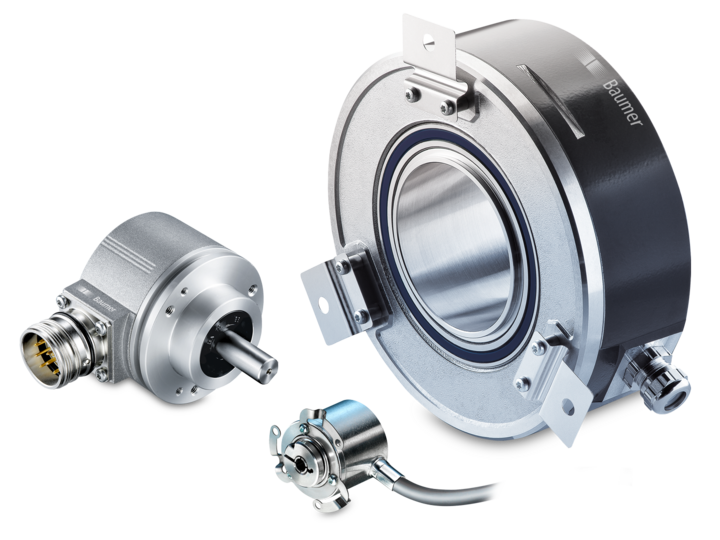

3. Speed-independent triggering

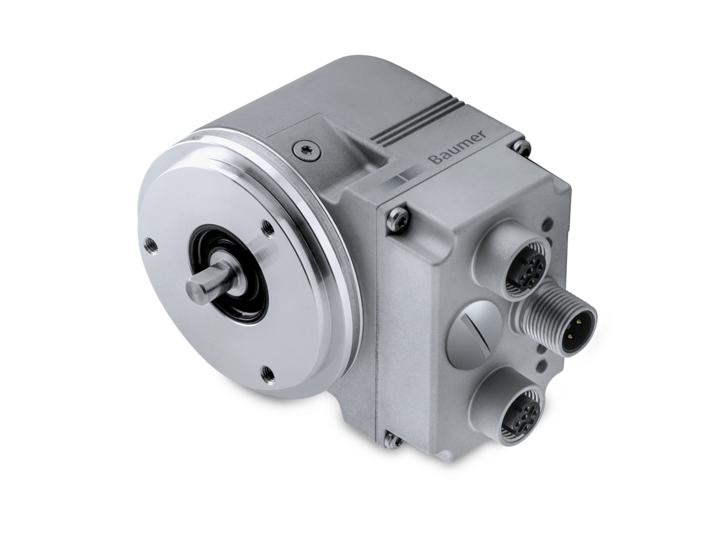

Direct connection of incremental rotary encoder to the smart camera for speed-independent quality control

High quality control reliability

- Virtually jitter-free rotary encoder signals allow precision camera triggering over the entire speed range

- Monolithic opto-ASIC with high integration density facilitates stable signals even under shock and vibration conditions in continuous operation

- Robust sealing concept for guaranteed high protection class IP 67

High degree of flexibility

- Flexible parameterization from 1 … 65536 pluses/ revolution

- Selectable TTL or HTL output signal level

Product Spotlight:

Industrial encoders incremental

Rotary encoders / angle sensors

4. Quality control of filled containers

Image processing and identification with vision sensor

High operational reliability

- Contour-based evaluation by FEX® image processor for stable quality control also with fluctuating surface properties

- Easy and reliable setup of color checks with ColorFEX® 3D color assistant

- Robust thanks to industrial design in rugged metal enclosure of protection class IP 67

High degree of flexibility

- No mechanical object alignment necessary thanks to automatic FEXLoc® 360 ° position tracking

- 22 different check tools are able to check up to 32 features per job

- Up to 255 jobs can be stored in the sensor with backup option via FTP server

- High-speed mode with up to 100 checks/minute

- XC series with interchangeable lenses, including patented modular IP 67 lens protection

Product Spotlight:

VeriSens vision sensors

Smart Vision Sensors

5. Live image quality assurance

Web interface with MultiViewer to display up to 16 VeriSens® on one screen

Reduced implementation time and costs

- Configurable web interface for application-specific operation and monitoring in only a few minutes

- No additional software costs

- Integrated VeriFlash flash controller for reduced programming and integration expenditure

- Error image memory in sensor

- Integrated FTP client allows error images to be stored on a FTP server

Product Spotlight:

VeriSens Application Suite

Software

The drive technology uses stable signals from rotary encoders to ensure the containers run at a low noise level through the machine. This not only has a positive effect on machine performance but also reduces conveyor belt wear.

1. Buffer table and infeed conveyor synchronization

Incremental industrial rotary encoders with precise optical scanning

Reduced storage and startup costs

- Differing requirements parameterizable with only one rotary encoder variant from 1 … 65536 pulses/revolution

- Shorter startup times by simple reparameterization of the encoders on site with handheld programming tool

- All commonly used mechanical interfaces available

High operational reliability

- Immune to shock and vibration thanks to high integration density

- New optical sensor technology offers high signal and control performance

Product Spotlight:

Industrial encoders incremental

Rotary encoders / angle sensors

2. Master rotary filler axis

High control performance provided by absolute industrial rotary encoders

High system performance

- Synchronization of various machine modules with only rotary encoder and up to 5 precision incremental outputs of varying resolution

- High precision position and trigger signals with integrated error compensation and filtering of machine vibration

- Adjustable signal resolution for flexible adaptation to machine configuration

- Functionally reliable incremental signal for efficient setup

- Synchronous position output with ultra-low jitter in ± 0.6 μs range with Powerlink

- Freely selectable position resolution without conversion in the PLC and Powerlink cross-traffic for ultra-precise synchronization of various axes

High operational reliability

- Safety first – safe incremental rotary encoders with SIL2

- Reliable speed with standard square-wave signals simply integrated in existing architectures

- Simpler verification of safety functions thanks to certified conformity (IEC 61508)

- Long service life of rotary encoders ensured by statistical process checks and automated final inspections

- Absolute rotary encoder with 18-bit resolution and a repeat accuracy of ± 0.1 °

Product Spotlight:

58 mm – compact precise optical

Absolute industrial encoders

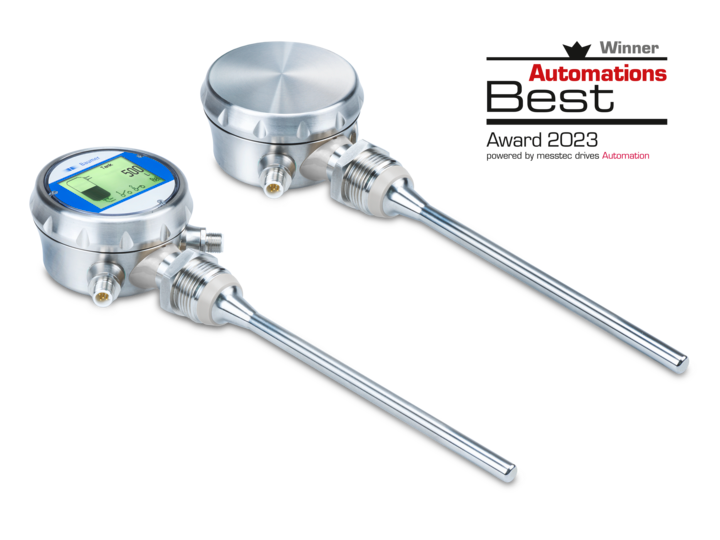

Packaging sizes vary according to customer orders. For this reason, machine shafts often require mechanical alignments.

The Baumer spindle position displays are a convenient solution to reduce time for machinery adaptation and ensure process reliability during format alignments.

Efficient spindle positioning on packaging machines…

…becomes necessary as soon as the products to be packaged also change in their dimensions. Packaging machines must be fast and flexible to efficiently package the high product variety and small batch sizes on the same machine. At the same time, process reliability is required in all industries, which is also supported by the spindle position display.

Baumer offers spindle position displays for packaging and labeling machinery in:

- Primary packaging

- Secondary packaging

- End of Line Packing

Using a built-in high-resolution optical multiturn absolute encoder, the spindle position indicator achieves the required accuracies of spindle positioning in packaging machines. Even in the absence of power, the spindle position indicator detects an adjustment. This prevents unplanned stops of the machine after restarting.

Packaging machines

Filling and dosing systems

Format adjustment

Efficient spindle positioning of machine axes

Benefits

The benefits of electronic position displays in multiple manual format adjustment operations per day:

Tiếng Việt

Tiếng Việt