Consulting, Solutions

CleverLevel® level switches

Truly clever point level detection.

The clever alternative to vibrating forks

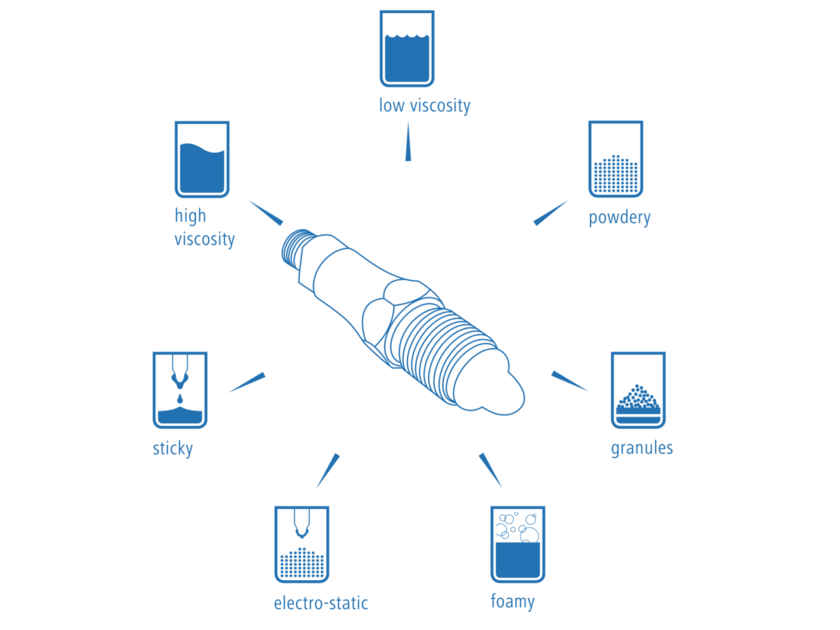

The level switch CleverLevel® is the solution for a variety of applications for which standard vibrating forks are used today. It offers a consider- able advantage, especially for applications with adherence, which it automatically masks. With the Adaptive-Trigger function, the Clever- Level® is now one more step ahead of vibrating forks – it automatically adjusts to all media even without parameterization. Thanks to its limited installation depth it also ensures low process interference.

Products Portfolio

Pre-parameterized point level sensor in field housing

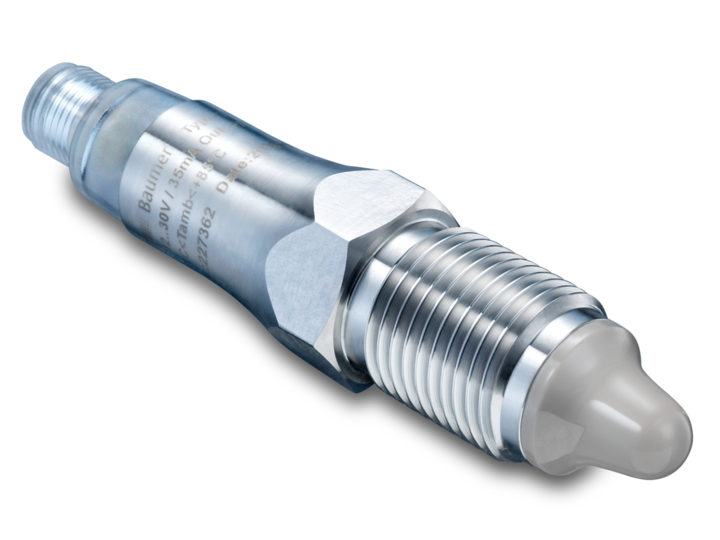

CleverLevel LFFS

Advantages due to the compact design

- Easy to clean

- No alignment of the sensor tip necessary

- Limited turbulences and low flow resistance

- Also suitable for small pipe diameters

Clever3 – your benefits

The original is one step ahead: The CleverLevel® series from Baumer now offers even more options – regardless of the medium or measurement task, when it comes to point level detection we always offer you the optimal solution.

Even media detection without parameterization is no problem with the innovative PL20. In addition, thanks to the optional analog output, media differentiation is also possible.

1. Quick and easy integration

Point level detection

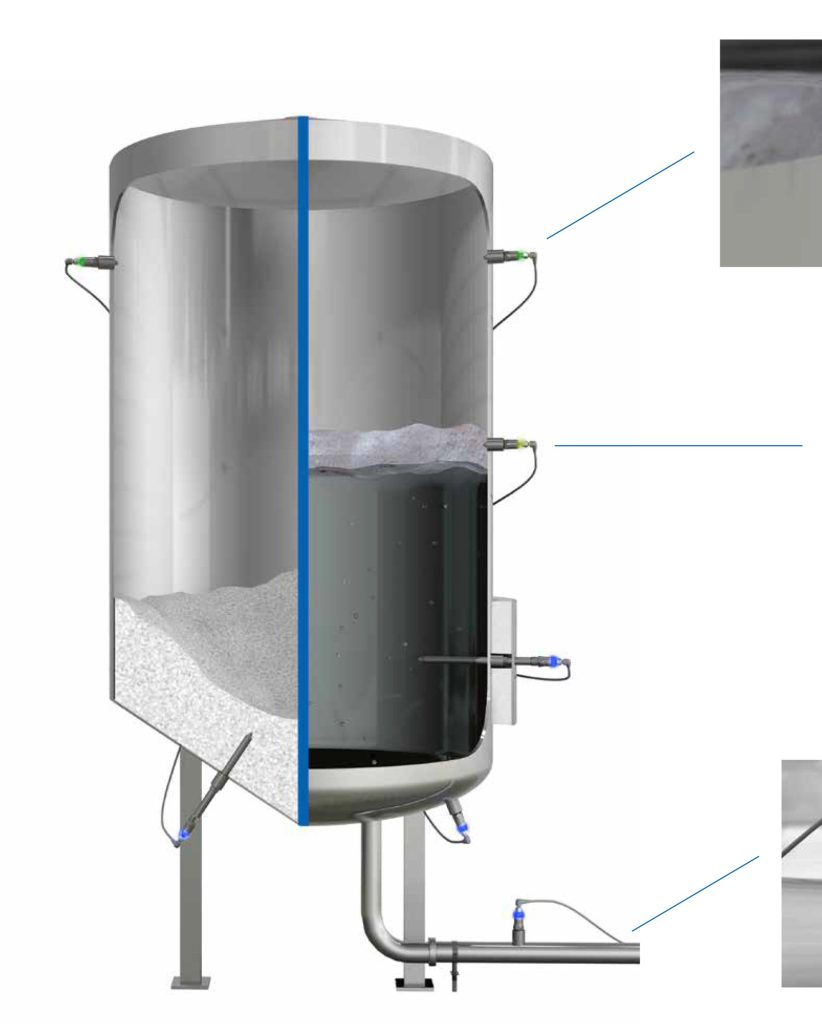

Regardless of the media, CleverLevel® level switches reliably and precisely detect the point level of tanks, containers, and pipes. This way, the possibility of running empty can be detected early on and overfilling is prevented.

Foam and separating layer detection

With the Window-Trigger, separating layers – for example, beer and foam or oil and water – can be detected. Thanks to the two switch- ing outputs, the CleverLevel® can be parameterized in such a way that the medium is reliably detected and the different liquids dif- ferentiated. The graphic evaluation allows the process to be tracked and optimized even more effectively.

Dry-run protection for pumps

Dry running of pumps is a critical process problem. It can result in dosage deviations or even damage. With its quick response time, the CleverLevel® easily masters this challenge. Faster switching off saves valuable resources.

Adaptive point level detection without parameterization.

The flexible adjustment of systems to short-term requirement changes is an increasingly common production challenge that affects system and machine constructors as well as the food processing industry. Ensuring this flexibility requires sensor technology that can meet these challenges. With our Adaptive-Trigger, we can now provide you with the solution:

Automatic media adjustment

For applications in the food production sector with changing recipes or batch production, the PL20 offers true added value with adap- tive setting of the switching point. Without the need for parameterization, the sensor adjusts the switching point to the medium and detects it reliably. This ensures maximum flexibility with minimum set-up times.

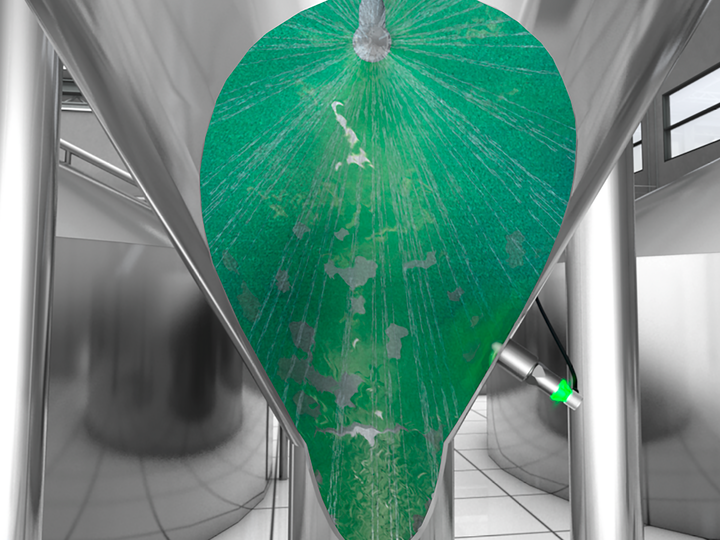

Unaffected by adherence

Optimized for cleaning processes

Added value with an additional analog output.

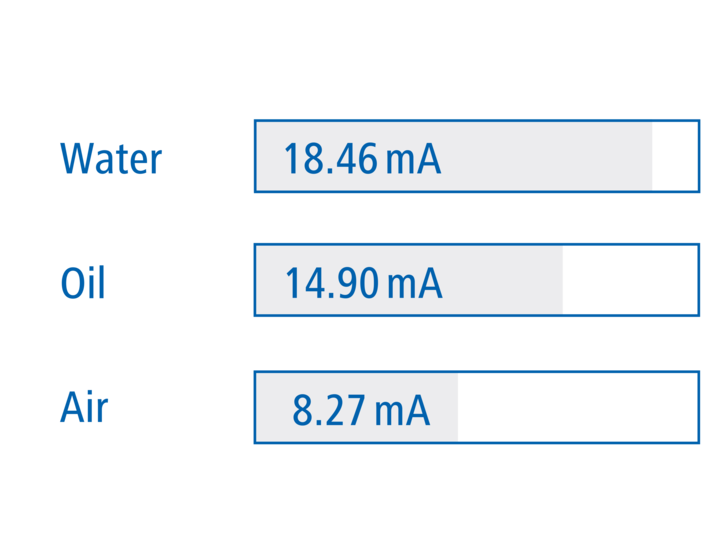

In addition to the switching signal, analog values ranging from 4 … 20 mA can be read out. This way, in addition to the point level, other measured values are also available that provide additional information about the process.

Media differentiation

With the 4 … 20 mA signal, media such as oil and water or different powders can be differentiated. With the help of the Baumer FlexPro- gramer, these can also be presented graphically when setting the system. It is also possible to invert the measured analog values.

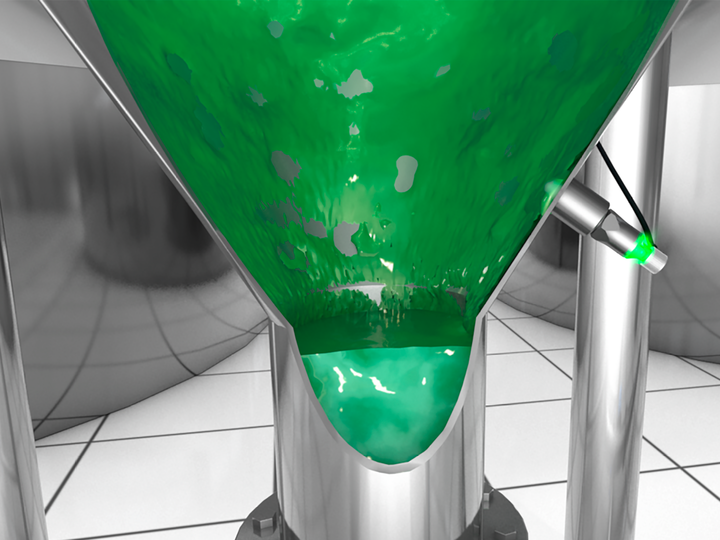

Cleaning process evaluation

The 4 … 20 mA analog signal can be used to evaluate whether the sensor tip has been cleaned or if remnants of the medium are adhered to it. In addition it is possible to detect whether the single cleaning steps have taken place.

Moisture determination

The analog signal can be used to determine the moisture content or degree of dryness of the medium, especially in the case of solids and granulates.

Baumer KingCrown – we make metal glow.

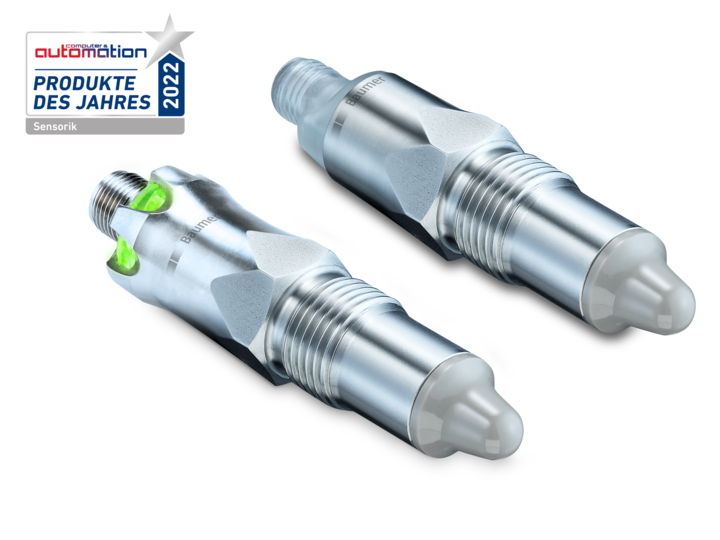

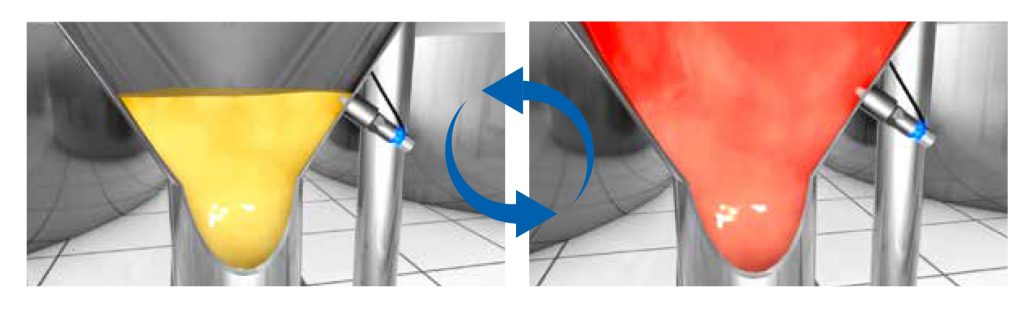

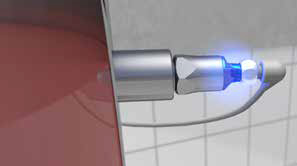

Robust 360° process indication

Process transparency – anytime, anywhere. The robust visual process indication provides real-time informa- tion about the status of the process. Five defined colors indicate whether the process is proceeding as intended, the sensor is switching, or if there is a malfunction.

Additionally, the color can be used to visualize the medium being measured. Thanks to the 360° LEDs, this information is visible from all locations, allowing reliable processes. With its electrical stainless steel connection in combination with the visual process indication, the Baumer KingCrown is a robust, reliable solution. The proTect+ impermeability concept ensures the long-term impermeability of the sensor technology.

360° process indication

The 360° LED crown with five defined colors provides im- mediate visual indication of the system’s operating status at all times. At the same time, potential sensor failures can be indicated and directly located.

- Five defined colors for real-time status display

- Visible from a distance from all directions – without a blind spot

- Clearly visible during daytime

WEBINAR: Smart Sensor Solutions for CIP Processes

Join us for an exclusive webinar hosted by Servo Dynamics in partnership with Baumer, designed to introduce advanced sensor solutions tailored for CIP (Clean-In-Place) processes in the Food & Beverage industry.

Tiếng Việt

Tiếng Việt