Consulting, Industrial Automation, News

Wireless Functional Safety Applying CIP Safety on Mobile and Remote Devices with Wireless Communication

In the past 15 years, industrial communications have seen continuous development due to increased system efficiency demands, supported by consumer communication technologies and IT, which help reduce costs. At home and in offices, there are high expectations for wireless network performance, making it a preferred connection method in these environments. Therefore, wireless solutions are becoming increasingly popular in industrial environments for logical reasons. Wireless industrial communications enable more efficient production in many areas such as manufacturing, logistics, and remote monitoring, among others.

- Flexible plant design and modularization

- Remote process control tools

- Data collection on legacy devices

- Automated guided vehicles (AGVs)

- Autonomous mobile robots (AMRs)

- Independent cart technology (ICT)

- Automated storage and retrieval systems (ASRS)

- Predictive analytics for mobile machinery

- Reduced wiring for clean design

With each technological advancement, wireless communication achieves better performance, leading to more potential applications. However, companies implementing wireless communication in operational environments need to address certain cultural and technical barriers, such as ensuring employee safety. Overcoming these challenges is crucial for successfully integrating wireless solutions in industrial environments.

What about safety? Safety is particularly critical for mobile devices, mobile machinery, reconfigurable factories, and anywhere humans interact with hazardous targets in industrial control systems. These applications pose specific challenges for industrial communication, such as how to wirelessly communicate industrial information and how to ensure employee safety when interacting with mobile machinery. Wireless communication has made significant improvements, and many applications can now be implemented with functional safety as part of the design.

How to ensure wireless safety? Firstly, consider functional safety requirements in a broad sense and how they operate through industrial communication. There are many standards related to functional safety in different contexts. Common themes for industrial control systems include:

- Minimizing the risk of component failure or system failure

- Quantifying the risk of failure after mitigating measures have been taken

- Detecting when failures occur

- Ensuring that failures always lead to a safe state

This is achieved using good design practices, applying redundant components, conducting statistical analysis of failure modes, and running regular diagnostics among other techniques. Modern standards for safe system design, such as IEC 61508 and IEC 62061, specify how to apply these techniques to electronics in systems, while IEC 13849 adds mechanical systems. How do these good principles apply to such a communication network, particularly wireless?

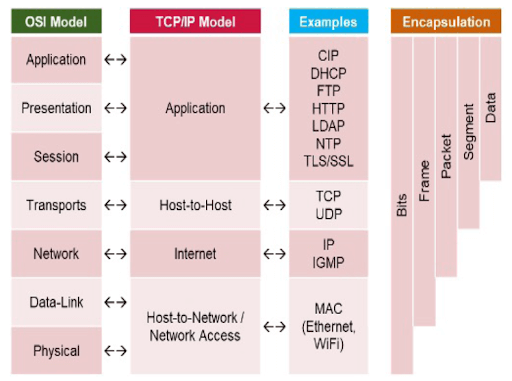

The foundation of EtherNet/IP We will begin by examining how standard industrial communications operate. Examining the OSI model and TCP/IP model for communication is useful to understand how different parts of the communication system work together for the EtherNet/IP™ industrial communication protocol.

- Data must be transmitted between two devices created at a higher application level, using the Common Industrial Protocol (CIP™). This is the same layer that familiar functions like HTTP and SMTP exist in.

- At the transport layer, CIP information is packaged, usually with a TCP or UDP header in the case of EtherNet/IP.

- At the network layer, the specific server IP address determines the routing of information packets through the industrial Internet.

- At the communication layer, CIP packets are transmitted via dedicated network or device connection solutions.

- Physical Layer: This is the lowest layer in the OSI model, defining the physical aspects of the connection, such as cables, frequency ranges, and connection standards.

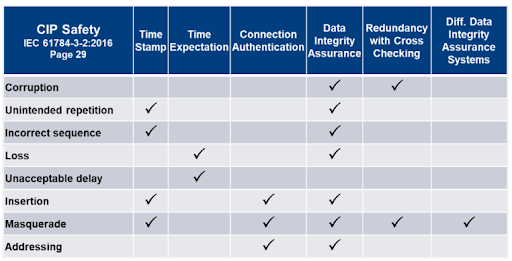

Applying CIP Safety on Mobile and Remote Devices with Wireless Communication In the context of applying functional safety in wireless communication networks, CIP Safety plays a crucial role. CIP Safety is a software and hardware safety feature applied to ensure that control signals and data are safely transmitted between devices in the control system.

Diagnostic capabilities: CIP Safety allows devices in the communication network to send and receive diagnostic data, which is essential for efficient system testing and maintenance. Integrating diagnostics into wireless systems helps minimize machine downtime and increase overall factory or plant productivity.

Deploying wireless networks: To successfully deploy a wireless network using CIP Safety, companies need to comply with international safety standards, such as IEC 61508 and IEC 62061, to ensure that every aspect of the system is securely protected.

Safety challenges in wireless networks: One of the biggest challenges in applying CIP Safety in wireless networks is ensuring the stability and reliability of connections. Wireless networks may encounter issues such as signal strength durability, interference, and connection failures. Network design must consider these factors to ensure continuous functional safety.

Applications in industries: CIP Safety in wireless networks can be applied in many industrial sectors such as automated manufacturing, logistics, autonomous guided vehicles (AGVs), autonomous mobile robots (AMRs), automated storage and retrieval systems (ASRS), and many other applications. These are industries where the use of mobile or automated devices interacts closely with humans and requires high safety assurance.

Conclusion Applying functional safety in wireless communication networks is not just a trend but a vital necessity in today’s industrial environments. CIP Safety plays a crucial role in ensuring that control systems and related devices operate safely and efficiently. Applying CIP Safety in wireless networks requires careful consideration of technical and safety factors to ensure that all operations proceed smoothly and effectively.

Contact us for quotation and support

[formidable id=”1″]Contact Information

Thanks for visiting our website. For more information, please contact:

Servo Dynamics Engineering Co., Ltd

Tel: +84 28 3740 2128

Email: sales@servodynamics.com.vn

Website: www.servodynamics.com.vn

Official Account Zalo: Servo Dynamics Engineering

Saigon

4/1B Luong Dinh Cua Str., An Khanh Ward, Thu Duc City, HCMC, Vietnam

Tel: (84-28) 3740 2128

Fax: (84-28) 3740 2129

Da Nang

120 Xo Viet Nghe Tinh, Hoa Cuong Nam Ward, Hai Chau District, Da Nang, Vietnam

Tel: (84-23) 6361 1128

Ha Noi

Unit 05, 15th Floor, Han Viet Tower, 203 Minh Khai Street, Hanoi, Vietnam

Tel: (84-24) 3632 1617

Fax: (84-24) 3632 1618

Tiếng Việt

Tiếng Việt