Completed Project, Industrial Automation

What are Ethernet/IP Signal Tower Lights? Features & Functions

What are Ethernet/IP Signal Tower Lights?

In the context of Industry 4.0, signaling devices are no longer mere indicator lights; they have become “smart links” in the automated network. The emergence of Ethernet/IP Signal Tower Lights clearly demonstrates this shift, moving the role of status indicators from passive components to active communicators within the industrial automation network.

The Concept of Ethernet/IP

Definition: Ethernet/IP (short for Ethernet Industrial Protocol) is a leading industrial network protocol, developed by Rockwell Automation and managed by the ODVA (Open DeviceNet Vendor Association). This protocol allows automation devices to communicate over standard Ethernet networks.

Features: The core strength of Ethernet/IP is its ability to leverage universal standard Ethernet technologies (TCP/IP, UDP/IP) and operate at the Application Layer through CIP (Common Industrial Protocol). CIP provides a unified communication framework allowing devices from different networks (such as Ethernet/IP, DeviceNet, ControlNet) to communicate consistently. By utilizing readily available Ethernet technology, the protocol has become popular, easy to integrate, and achieves fast, reliable data transmission speeds.

Definition of Ethernet/IP Signal Tower Lights

An Ethernet/IP Signal Tower Light is a signaling stack light device designed with the capability to integrate an Ethernet/IP communication module internally. Instead of merely receiving voltage on/off signals, the EIP tower light is an intelligent device that receives and responds with data packets via a single Ethernet cable.

Distinguishing from Traditional I/O Signal Tower Lights:

- I/O Light: Operates based on physical signals (24VDC/220VAC). Requires N wires (N is the number of light tiers + buzzer) and N terminal I/O ports. Functionality is limited to display.

- EIP Light: Operates based on data packets. Requires only one network cable (RJ45), eliminating the need for physical I/O wiring for each tier. The device has two-way communication capability, sending diagnostic data back to the controller.

Structure and Specific Operating Principles of Ethernet/IP Signal Tower Lights

General Structure and Types of Light Tiers

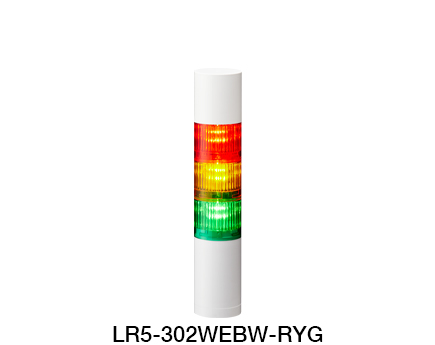

The EIP Signal Tower Light maintains the standard modular structure, allowing users to flexibly customize the number and color of the light tiers:

- Standard Colors:

- Red: Critical Error (Alarm/Stop).

- Amber/Yellow: Warning/Standby.

- Green: Normal Operation (Run/OK).

- Blue/White: Quality, Custom status, or Maintenance Call.

- Common Number of Tiers: The 3-tier signal tower light (Green-Amber-Red) is standard, but extended configurations like 2-tier signal tower light, 4-tier signal tower light, and 5-tier signal tower light are used for more complex display requirements.

- Voltage Classification: The most common supply voltage in industrial environments is 24VDC. Therefore, 24V 2-tier signal tower lights or 3-tier 24V configurations are the norm.

Ethernet/IP Network Connection Principle

Integrating the EIP signal tower light into the industrial network relies on the Master-Adapter communication model and utilizes two main types of messaging:

- Role of the Ethernet/IP Master (PLC or Controller): The Master device, typically a high-performance PLC (e.g., Allen-Bradley ControLogix/CompactLogix), sends control commands and manages all signal tower lights on the network.

- Role of the Ethernet/IP Adapter (The Light as an Adapter): The signal tower light acts as the intelligent end device (Adapter). It uses Implicit Messaging (I/O Data) to receive real-time control commands (on/off/flash light, activate buzzer) and sends back status I/O data.

- Connection Method (Ethernet/IP connection): The signal tower light is plugged directly into the industrial Ethernet network (often via a Switch, or in a daisy-chain topology for models with 2 ports), establishing a high-speed Ethernet/IP connection and completely eliminating traditional I/O signal wiring.

Outstanding Features and Functions of Ethernet/IP Signal Tower Lights

The Ethernet/IP Signal Tower Light is an essential component for building an effective IIoT (Industrial Internet of Things) system.

Two-Way Data Communication and In-Depth Diagnostics

- Functionality: The biggest difference is the two-way communication capability via CIP, which allows the tower light not only to display status but also to send a range of critical diagnostic data (Diagnostic Data):

- Fault reports for broken LEDs.

- Operating life information (hours of operation).

- Internal temperature reports.

- Vendor Specific Error Codes.

- Flexible Changeability: Engineers can precisely control light intensity, flashing frequency, rotation style, and buzzer sound remotely via data registers in the PLC, enhancing fault reaction and identification capabilities.

Cost Reduction and Simplification of Wiring Systems

- Benefit: A traditional 5-tier I/O light would require at least 6-7 signal wires back to the control cabinet. With the Ethernet/IP Signal Tower Light, all control and diagnostics require only one Ethernet cable. This minimizes the total number of I/O wires, saves space in the control cabinet (by reducing I/O modules), and significantly shortens installation time.

- Integration: They are highly compatible with large control systems using EIP (Rockwell Automation, Omron, Schneider Electric, etc.), ensuring Plug-and-Play capability.

Easy Installation and Configuration (Ethernet Configuration)

The installation and Ethernet configuration process for EIP tower lights is standardized, helping engineers quickly put the device into operation:

- IP Address Assignment: The device supports automatic IP assignment methods (DHCP/BOOTP) or manual configuration (Static IP).

- Using EDS File: To integrate the device into the PLC programming software (e.g., Studio 5000), the engineer simply needs to import the EDS (Electronic Data Sheet) file of the signal tower light. This file contains all configuration information for I/O and data registers, simplifying the Ethernet configuration work and data mapping.

Practical Applications in Manufacturing Environments

Machine Monitoring and Error Alerting

EIP signal tower lights are indispensable signaling tools in:

- High-speed packaging/assembly lines: Signaling status stops due to lack of material, product jamming errors, or the need for maintenance.

- CNC Machines and processing equipment: Clearly displaying spindle operation status, overheating, or the need for a tool change.

- Automated Storage and Retrieval Systems (ASRS): Signaling the operational status of Automated Guided Vehicles (AGV/AMR) and main conveyors.

Optimizing Overall Equipment Effectiveness (OEE) and Predictive Maintenance

Data from the EIP signal tower light is a valuable source of information for performance analysis:

- OEE Measurement: The SCADA system can automatically retrieve data from the tower light regarding the precise time the red/amber light is active. This allows for far more accurate calculation of OEE (Overall Equipment Effectiveness) than manual data entry.

- Predictive Maintenance: Analyzing data on LED lifespan or overheating reports from the tower light allows the maintenance team to plan replacements or inspections before unexpected downtime occurs.

Flexible Network Expansion

Modern Ethernet/IP Signal Tower Light models often come equipped with two network ports (Dual-Port), allowing for a Daisy-Chain configuration. This helps minimize the number of switches required, simplifies wiring, and facilitates network expansion. Furthermore, using an Ethernet gateway allows for flexible integration of older I/O devices or other protocols into the EIP network.

Guide to Choosing the Right Ethernet/IP Signal Tower Light

Selection Criteria: Number of Tiers and Voltage

- Number of Tiers: The choice must match the complexity of the information. The 3-tier signal tower light (standard) is sufficient for 3 basic statuses. Ensure the ability to control each light tier and the buzzer independently over the network.

- Voltage: Always prioritize 24V 2-tier signal tower lights (or 3, 4, 5 tier 24VDC) to ensure electrical safety and maximum compatibility with the standard power supply of PLCs and automation devices.

Considering Protection Standards and Environment

The IP (Ingress Protection) standard is critically important:

- IP65: Fully dust-tight and protected against low-pressure water jets (suitable for general manufacturing environments).

- IP66/IP67 Lights: Mandatory for high-pressure washdown environments or areas with high humidity and significant dust. Choosing an IP66 light ensures durability and longevity in food processing or pharmaceutical areas.

Brand and Compatibility

To ensure stable network communication performance, prioritize brands with certified and ODVA-validated products:

- Patlite: A leader in LED quality, durability, and diagnostic features.

- Qlight: Offers a wide variety of models and reasonable costs.

- IDEC: Known for reliable control and signaling solutions.

- Hanyoung NUX: A Korean brand famous for its high-value, durable automation products. It offers various signal tower light series with diverse network communication options.

- Menics: Specializes in providing quality industrial signaling device solutions, favored in the Asian market for its diversity and excellent integration capabilities.

Patlite Ethernet/IP Signal Tower Lights: The Leading Solution

Overview of Patlite and the Ethernet/IP Product Line

Patlite, a Japanese brand, is synonymous with LED quality and physical durability in the signaling industry. Their Ethernet/IP product lines, such as the LR-EIP and NH-EIP series, are strictly designed to comply with ODVA standards, allowing for easy integration into Rockwell Automation systems. Patlite’s modular design allows for easy replacement of light tiers without rewiring, optimizing maintenance.

Superior Technical Specifications and Reliability

Patlite EIP signal tower light series offers absolute reliability:

- High Durability: Heat-resistant, impact-resistant polycarbonate housing, with high IP Ratings (typically IP66/IP67).

- LED Lifespan: Utilizes high-efficiency LED technology, achieving an operating life of up to 50,000 hours or more.

- Smart Features: Capability for brightness control (Dimming) and detailed fault diagnostics over the network, ensuring the system remains stable and transparent.

Servo Dynamics Engineering: Authorized Distributor of Patlite in Vietnam

If you are looking for a high-quality, durable, and easily integrated Ethernet/IP Signal Tower Light solution, Servo Dynamics Engineering is the official and reputable distributor of Patlite signal tower lights in Vietnam. We are committed to providing genuine products, in-depth technical support for industrial networks, and optimal EIP network integration solutions for your factory.

Tiếng Việt

Tiếng Việt