Consulting, Industrial Automation

What is a Force Sensor? Definition, Working Principles, and Applications

What is a Force Sensor?

A force sensor is an instrument that transforms various mechanical forces—such as weight, tension, compression, torque, strain, stress, or pressure—into electrical signals. These signals quantify the force’s magnitude and can inform operators or serve as inputs for machinery and process controls. They often transmit data to indicators, controllers, or computer systems.

While technically different from force transducers, the terms are often used interchangeably. Force measurement devices are increasingly critical in power equipment, engineering machinery, various operating machines, and industrial automation. These instruments vary in size, capable of measuring forces from mere grams to several tons.

Applications for these devices cover a diverse range, from bathroom scales and musical instruments to medical devices, automotive seat occupancy detection, and industry-specific process controls. We’ll discuss different types and their working principles.

How Do Force Sensors Work?

Just as a load cell operates on the principle of deformation due to an applied weight, a force probe (or force transducer) follows the same concept but primarily measures force in terms of tension, compression, and shear. The science behind the technology is similar to that of force transducers in that they use sensing techniques such as the piezoelectric effect, strain gauge, capacitive sensing, optical force sensing, and magnetic force measurement.

A force sensor operates on the basic principle of converting mechanical force into an electrical signal. This conversion happens in various ways (such as using strain gauges, piezoresistivity, or capacitance), but the underlying concept remains the same. The instrument’s operation proceeds through three sequential steps:

- Force Application: When a sensor is pressed, pulled, or squeezed, a mechanical force is applied to it.

- Internal Change: This force induces a physical change within the device, which may entail bending, stretching, or compressing its internal components.

- Electrical Signal Generation: As a result of this physical alteration, the internal properties of the instrument, such as resistance or capacitance, undergo modification. This change is then converted into an electrical signal that is proportional to the magnitude of the applied force.

Types of Force Sensors

When you start learning about force measurement tools, force transducers, or force probes, you’ll discover a variety of devices. Each type is uniquely designed to perform optimally under specific conditions and requirements. Let’s look at the main categories to better understand how they work.

- Strain Gauge Force Sensor: Measures force by transforming the deformation of the structure, caused by the applied force, into an electrical signal. This type of sensor is popular due to its accuracy, reliability, and versatility.

- Piezoelectric Force Sensor: Generates an electrical charge when a force is applied. They are best suited for dynamic force measurements because they can accurately measure rapid changes in force levels.

- Capacitive Force Sensor: Works on the principle of a change in capacitance due to deformation under applied force. Flexible units in this category are particularly suited for applications where low force measurement is needed.

- Optical Force Sensor: Measures the change in light intensity, frequency, or phase characteristics due to the applied force, making them ideal for applications requiring a high degree of precision and accuracy.

- Magnetic Force Sensor: Measures the change in a magnetic field due to an applied force. These sensors are often used in environments with high electromagnetic interference as they are immune to such disturbances.

Applications of Force Sensors

Force sensors find applications in a broad range of industries. In robotics, they are used to give robots a sense of touch or grip. In healthcare, these instruments are applied in devices like blood pressure monitors. The automotive industry uses them for quality control in touch-sensitive applications, while the electronics industry uses them to test the quality of switches, buttons, and touchscreens.

These devices also play a vital role in safety devices such as airbags in vehicles, where an immediate response is required. In the manufacturing industry, they ensure the precision of machinery operation by monitoring force variation during the production process. In addition to these, force probes are also used in aerospace, defense, consumer electronics, and more.

Advantages and Disadvantages of Force Sensors

This section outlines the pros and cons of the various sensor types discussed. Understanding these can assist in selecting the most suitable force measurement device for specific applications by providing a comparative overview.

Strain Gauge-Based Sensor

- Advantages:

- Relatively low cost.

- Excellent linear and hysteresis behavior, leading to high accuracy.

- Good temperature compensation when integrated with a Wheatstone bridge circuit.

- Capable of measuring both static and dynamic loads.

- High vibration resistance and fatigue strength.

- Outstanding long-term stability.

- Disadvantages:

- Non-linear model.

- Sensitive to temperature.

- Requires frequent calibration.

- Requires manual labor to apply strain gauges, which can be time-consuming and costly.

Piezoelectric Sensor

- Advantages:

- Favorable frequency response.

- Compact and easy to handle.

- Robust construction.

- Very little phase change.

- High natural frequency due to high stiffness.

- High load capacity and resilience under heavy cyclic loading.

- Wide measurement window.

- Exceptionally small design.

- Disadvantages:

- Sensitive to high temperatures.

- Some crystals are water-soluble and disintegrate in highly humid environments.

- Only suitable for dynamic measurement; not appropriate for static conditions.

- The electrical interface requires high-quality cables.

- Low output requires an external electronic circuit.

Capacitive Sensor

- Advantages:

- Can detect non-metallic targets.

- Simple construction.

- It can be adjusted to work with various materials.

- Can identify both solid and liquid targets.

- Lower cost.

- Highly sensitive and requires minimal energy to operate.

- High resolution and frequency response.

- It can be used to measure force, humidity, and pressure.

- Disadvantages:

- Performance is impacted by changes in external factors like humidity and temperature.

- Capacitance measurement is more difficult than resistance measurement.

- Less precise compared to inductive sensors.

Choose the Right Force Sensor

Choosing the right force sensor depends on multiple factors such as the type of force to be measured (tension, compression, shear), the range of force, accuracy requirements, environmental conditions, and the space available for installation.

Picking the right force sensor is like finding the perfect tool for the job. Here are some key things to consider when making your choice:

- How Much Force Can It Handle? The force sensor needs to be strong enough to handle the forces you expect it to measure. If you’re measuring a delicate butterfly landing, you don’t need a sensor built for a car crash.

- How Sensitive Is It? Some force sensors have a feather-light touch, able to detect the slightest pressure. Others are more like sturdy gloves, good for feeling strong pushes and pulls. Choose a sensor with the right sensitivity for your needs.

- What Environment Will It Be In? Consider the environment where the sensor will be used. Is it hot, cold, wet, or dusty? Choose a force sensor that can handle those conditions without getting damaged or giving inaccurate readings.

- Does It Fit the Space? Not all force sensors are created equal in size. Some are tiny enough to fit on your fingertip, while others are as big as a car engine. Make sure the sensor you choose is the right size for the space you have available.

- How Much Can You Afford? Just like any other tool, force sensors come in different price ranges. Consider your budget and choose a sensor that offers the features you need at a price you can afford.

Remember, a force sensor is more than a device—it’s a critical part of your system that ensures accuracy, efficiency, and safety.

Baumer Force Sensor: The Complete Measurement Chain

Baumer offers a comprehensive portfolio of force sensors designed for a wide range of forces and installation options. To ensure a simple and fast connection to your processes, Baumer also provides corresponding measuring amplifiers and connection cables. These measuring amplifiers convert the electrical signal from the sensor into analog values, which can then be transmitted to the control system. Depending on the input card, the measuring amplifier is available with either current or voltage output.

Your Benefits with Baumer

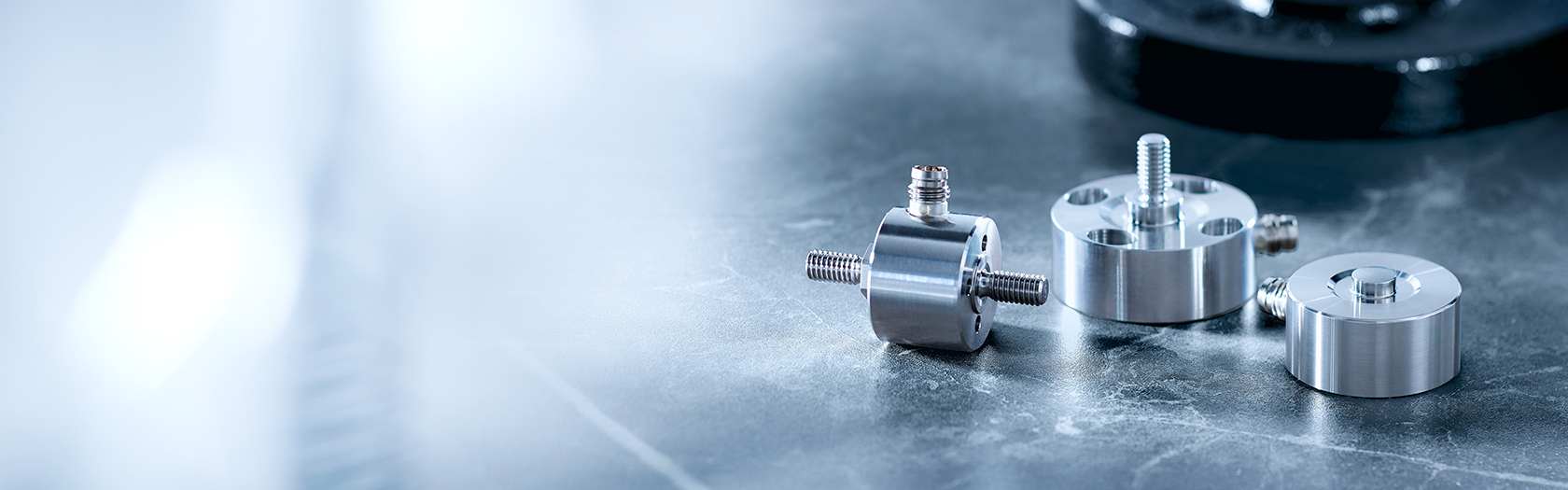

- Quick and Easy Selection: Find the right force sensor for your application quickly and easily with our intelligently designed portfolio. Our selection is clearly structured by different connection options, and the uniform thread size within a series, regardless of the force range, limits design risks.

- Reliable Force Measurement: Our force sensors are designed for low fatigue with 100% oscillatory width for dynamic applications across the entire measurement range, backed by decades of experience in manufacturing.

- Small and Flexible: With various sizes and shapes, our small-diameter sensors are perfect for limited spaces and can be quickly integrated into machine and equipment designs.

- Robustness for Harsh Environments: Baumer’s sensors feature stainless steel housings for reliable use in demanding industrial sectors. They are hermetically sealed for advanced impermeability and have exceptional shock and vibration resistance due to their fully welded design.

- Short Delivery Times & Easy Commissioning: Benefit from fast delivery from our warehouse. Our plug & play sensors allow for easy replacement without complex adjustments on the machine.

Key Applications

DMS-based force sensors, also known as force transducers or load cells, are ideal for force measurement in most applications, especially when measuring small forces. With an optimally coordinated product portfolio for 0–20,000 N, Baumer covers a multitude of applications. Thanks to their robust sensor bodies, they can also be used in areas with high demands. In addition to force sensors, Baumer also produces strain sensors for measuring higher forces, which are simple to install directly into the structure.

- Component Stress Monitoring for Ball Bearings: Force sensors reliably monitor the stresses on ball bearings to detect overloads, preventing failures and machine downtime.

- Monitoring Mounting Force: Force measurement simplifies the monitoring of mounting processes, helping to avoid expensive recalls and reworking.

- Monitoring Fusion Forces: Force sensors ensure continuous force monitoring in fusion processes like ultrasonic welding, clinching, or riveting, guaranteeing compliance with quality requirements.

- Overload Protection: On driverless transport vehicles, force sensors on booms can detect overloads, preventing robots from tipping over.

- Determining Filling Quantity: By measuring the weight of tanks, force sensors allow for the determination of fill levels or loads, enabling early detection of low stock levels.

- Monitoring Retention Forces: In processing centers, force sensors on clamping devices measure retention forces to improve quality and safeguard processing procedures.

- Force Measurement for Testing Machines: Force sensors in tension testing machines help determine material-specific properties, providing crucial information about the elasticity and load-bearing qualities of a material.

Servo Dynamics Engineering: Authorized Distributor of Baumer in Vietnam

Through this article, we hope you have gained a comprehensive understanding of what a force sensor is, how it works, and how to choose the right one for your application. If you are looking for a high-quality, reliable, and precise force measurement solution, look no further than Baumer.

As the official authorized distributor of Baumer in Vietnam, Servo Dynamics Engineering is committed to providing genuine products and comprehensive support. We not only supply Baumer’s complete product portfolio, from sensors to measuring amplifiers and connection cables, but also offer dedicated technical consulting, installation support, and after-sales service. With Servo Dynamics, you can be confident that you are getting the best products and expert assistance for all your force measurement needs.

Tiếng Việt

Tiếng Việt