Consulting

What is Armoured Cable? Structure, Classification & Detailed Applications 2025

Have you ever wondered what type of cable is durable enough to withstand all harsh conditions, from direct burial underground to heavy industrial environments? The answer is the Armoured Cable.

An Armoured Cable is not just an electrical cable; it is a mechanical and telecommunications solution designed with a solid protective sheath, ensuring safety and stability for the system.

So, what exactly is armoured cable, what is its structure, and why is it so vital and widely used? Let’s take a detailed look at this “silent hero” in modern engineering.

What is Armoured Cable?

Concept of Armoured Cable

An Armoured Cable is a type of cable (which can be an electrical cable, fiber optic cable, or mechanical steel cable) equipped with one or more layers of protective metallic armour on the outside. This metal layer is the core distinguishing feature compared to conventional cables.

The main purposes of the armouring layer are:

- Enhancing mechanical strength: Resisting stresses like tension, compression, impact, and damage from rodents.

- Protecting the cable core: Providing corrosion resistance, UV protection, and extending the cable’s lifespan.

- Electromagnetic Interference (EMI) Shielding (for electrical/telecom cables): Acting as an effective shielding layer.

Why is Armoured Cable Widely Used?

Armoured cable is the optimal solution for applications requiring high durability and absolute safety, especially in harsh environments. Armoured cables offer resistance to corrosion from acid rain and damage from rodents, providing high safety, stability, and reliable performance.

A significant advantage is the ability to Direct Bury the armoured cable without the need for protective pipes (conduits) or trunking, resulting in substantial savings on material costs and installation labor.

Armoured Cable vs. Ordinary Steel Cable

The difference lies in the Purpose and Structure:

Armoured Cable

- Purpose: Protection and Transmission (Power, signal, or tensile force)

- Structure: Multiple layers (Conductor core, insulation, metallic armour, outer sheath)

- Main Application: Electrical systems, Telecommunications, ACSR Steel-reinforced Aluminium cables

Ordinary Steel Wire Rope

- Purpose: Force Transmission (Lifting, bracing, pulling, anchoring)

- Structure: Strands of steel wires twisted into ropes, no outer sheath

- Main Application: Cranes, Winches, Guy wires, Dock/Port anchoring

Note: “Armoured Steel Cable” (used mechanically) is a classification of armoured cable, where the core is a steel cable and is covered with an outer layer of plastic/PVC to resist corrosion.

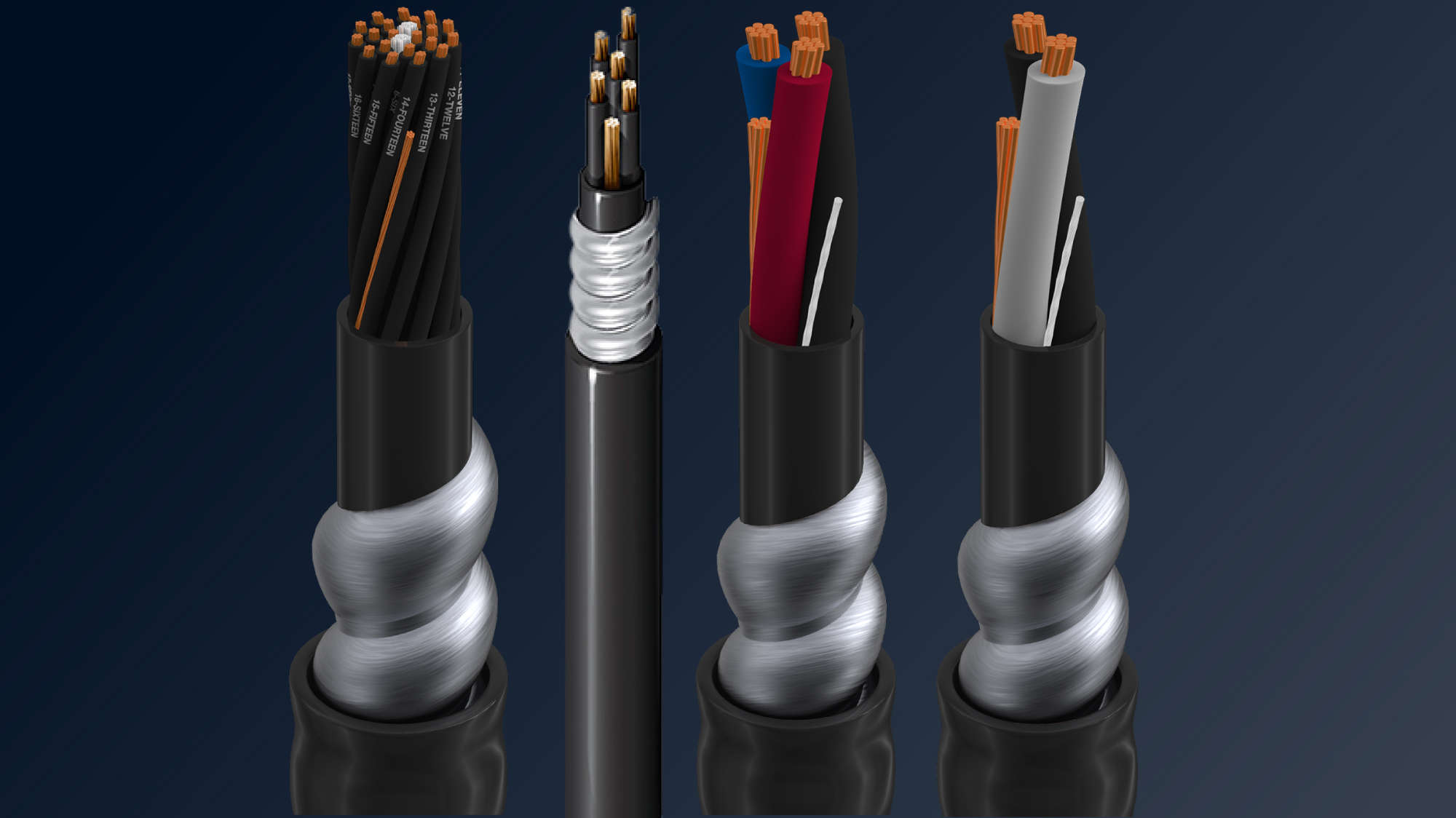

Structure of Armoured Cable

The structure of armoured cable can vary depending on its type (mechanical, electrical, optical), but fundamentally, it includes the following components:

1. Metallic Core Layer

This is the central part, playing the primary role:

- Conductive/Signal Core (For electrical/optical cables): Usually copper or aluminum conductors (electrical cables) or optical fibers (fiber optic cables). Modern cables, such as XLPE (Cross-Linked Polyethylene insulated) cables, can also be combined with an armour layer to enhance durability.

- Load-Bearing Core (For mechanical cables): Typically stranded Steel Wire Rope.

2. Protective Armour Layer

This is the most critical component, creating the “armoured” characteristic of the cable. Common armouring materials and techniques include:

- Steel Wire Armoured (SWA): Uses spirally wound steel wires to form the highest mechanical protection layer. Commonly used in underground systems, power networks, and outdoor lighting systems.

- Steel Tape Armoured (STA): Uses overlapping steel tape strips. The protection is thinner, suitable for indoor installation or underground in restricted spaces where protection is still needed.

- Aluminum Wire Armoured (AWA): Uses aluminum wires instead of steel wires, resulting in a lighter cable. Often preferred in applications requiring weight reduction, such as long-distance power transmission or distribution in industrial environments.

Related Technical Standards

In Vietnam, the installation and manufacturing of armoured electrical cables must comply with important standards such as:

- TCVN 5935 (equivalent to IEC 60502): For PVC-insulated power cables.

- TCVN 6610 (equivalent to IEC 60227): For XLPE-insulated power cables.

- TCVN 9208:2012: Regulations on the installation of electrical cables and conductors in construction works.

- QCVN 12:2014/BXD: National Technical Regulation on electrical systems in buildings and public works.

Popular Armoured Cable Classifications

Armoured cables are broadly classified based on the purpose of the inner core:

Armoured Cable for Mechanical – Lifting Industry

This is a type of Steel Wire Rope covered with an outer layer of PVC or PE plastic to protect the steel core from environmental impact, resist corrosion, and improve aesthetics. Scope: Used for anchoring, bracing, bundling, and suspension in construction and civil works. Common Specifications: Plastic-coated steel cable 3/8, 4mm, 5/8, 6mm, 8mm, 10mm, etc.

Armoured Power Cable

Electrical cable with conductors (copper/aluminum) protected by an armour layer (SWA, STA, AWA) for energy transmission. Scope: Low and medium voltage electrical systems, underground installation, main feeder lines. Types: Armoured electrical cable, steel mesh armoured cable. Typical Sizes: 1.5 mm2 (lighting), 4 mm2 to 6 mm2 (household sockets), 25 mm2 and above (heavy industrial load).

Armoured Fiber Optic Cable

Telecommunication cable with an Optical Fiber core protected by an armour layer (usually corrugated steel tape) to resist crushing and rodent damage. Scope: High-speed data transmission, installation of information transmission networks underground or in industrial environments. Types: Armoured fiber optic cable (data cable, TV cable, electronic cable).

Insulated Steel-Reinforced Aluminium Cable (ACSR/ACXH)

Cable used for overhead power transmission lines. The steel core provides strength and is clad with conductive aluminum on the outside, then covered with an insulation layer (ACXH) or left bare (ACSR). Scope: Overhead high/medium voltage power transmission and distribution lines. Common Specifications: 24 kV, 35 kV, 50 mm2, 240 mm2…

Medium Voltage Covered Conductor (MV Covered Conductor)

Cable used for medium voltage applications covered with a thick insulation layer to prevent short circuits upon contact with tree branches or other objects. Scope: Urban and rural medium voltage grids, where higher safety than bare wires is required. Common Specifications: 35 kV covered cable, 35 kV medium voltage covered cable.

Accompanying Accessories

To ensure effective installation of armoured cables, accompanying accessories are indispensable:

- Steel Cable Clamps (for mechanical cables, guy wires)

- Cable Terminations, Cable Joints, Glands (for electrical cables)

- Specialized Cable Cutters (for working on the armour layer).

Outstanding Advantages of Armoured Cable

Armoured cable provides the necessary protection and durability without the need for electrical conduits, couplings, or other complex accessories.

Excellent Mechanical Load Resistance

The solid steel armour protects the inner conductors from severe mechanical impacts. Armoured cables offer superior resistance to crushing, impact, and rodents, ensuring the safety of the cable core when direct buried or installed in industrial environments.

Corrosion and UV Resistance

The metal armour and high-quality outer sheath help the cable resist moisture and chemical ingress. This makes armoured cables ideally suited for use in wet, coastal, or outdoor environments where strong UV radiation is present.

Safety for Outdoor Installation

Armoured cable is designed to be more flexible than rigid electrical conduits, making installation easier in areas with many sharp, complex turns. The sturdy armour ensures the internal conductors remain unaffected in case of impact. Furthermore, this armour layer can be grounded to enhance safety, protecting users from electrical leakage.

High Durability and Long Lifespan

Thanks to comprehensive protection, armoured cables have a lifespan many times longer than ordinary cables, ensuring stable and long-term performance even in the harshest environments, thereby reducing maintenance and replacement costs.

Applications of Armoured Cable

Armoured cables are widely applied in many important areas of life:

In Mechanical – Construction – Engineering

Using plastic-coated steel cable for:

- Load-bearing cables for cranes and winches: Pulling wires for small industrial machinery.

- Fixed Bracing: Used as guy wires for telecommunication poles, electric poles, factories, bridges, and ferries.

In Electrical – Medium Voltage – Telecommunication Systems

Armoured cable is an essential component in:

- Power Systems: Power cables, branch cables, motor wires, electrical equipment wires, and overhead bare conductors (ACSR/ACXH).

- Information Transmission: Telephone cables, fiber optic cables, data cables.

- Mechanical and Measurement Devices: Most products in this field use armoured cables to ensure stable signal integrity.

In Lighting Infrastructure, Pole Hanging, and Bracing

- Outdoor Lighting Systems: Conducting electricity for streetlights and park lights.

- Suspension Systems: Used to suspend electrical cables and telecommunication cables on utility poles.

In Marine or High-Corrosion Environments

Armoured cable with specialized anti-corrosion protection is a mandatory choice for:

- Marine Structures: Submarine cables, power supply cables for offshore equipment.

- Chemical, Wet Areas: Ensuring the cable does not sustain rapid damage.

How to Choose the Right Armoured Cable for Each Need

Selecting the appropriate size and type of armoured cable is crucial to ensure safety, efficiency, and reliability for the system.

Selection Based on Load and Tensile Strength

- For Mechanical Cables: Choose a cable with a diameter and lay structure (e.g., 6×7, 6×19) suitable for the tensile force and maximum lifting load required by the project.

- For Electrical Cables: Select the conductor cross-section (mm2) suitable for the maximum current (Amperes) and voltage (kV) of the system. Larger sizes are suited for high-load applications.

Selection Based on Working Environment

- Direct Burial: Prioritize SWA (Steel Wire Armoured) cables or cables with special waterproof sheaths.

- Marine/Chemical Environments: Choose cables with an outer sheath made of chemical-resistant PVC/PE and galvanized steel or AWA (Aluminum Wire Armoured).

- Overhead Installation: Use ACSR/ACXH for power transmission or cables with UV resistance.

Checking Standards and Technical Certifications

- Ensure the cable meets Vietnamese technical standards (TCVN) and international standards (IEC).

- Request the supplier to provide full Quality Certificates (CQ) and Certificates of Origin (CO) to verify source and quality.

- Check characteristics: Mechanical durability, dielectric properties, and flame resistance.

Selection Based on Function: Pulling – Bracing – Suspending – Conduction

- Pulling/Bracing/Suspending (Mechanical Force): Choose plastic-coated steel cable or SWA cable.

- Power Conduction (Electrical Systems): Choose armoured electrical cable (SWA/STA/AWA) with the appropriate conductor cross-section.

Belden Armored Cables: Built to Last in Any Environment

Belden’s armored cables are designed to be tough and flexible. They offer excellent protection against crushing, impact, chemicals, and water. Plus, they’re very easy to install—saving you both time and effort.

Key Features and Benefits:

- Long-lasting durability: These cables deliver reliable performance even in the harshest environments.

- Lower indoor project costs: You can install the cables without using conduits, helping you reduce material and labor expenses.

- Cost savings for outdoor projects: No need for extra protective tubing when burying the cables directly underground—ideal for outdoor use.

With Belden armored cables, you can trust that your system will run safely and efficiently.

Frequently Asked Questions About Armored Cable

-

What’s the difference between SWA and AWA cables?

The primary difference between SWA (Steel Wire Armoured) and AWA (Aluminum Wire Armoured) cables lies in their armoring material.

- SWA cables use steel wire armor, making them better suited for applications requiring high mechanical protection.

- AWA cables use aluminum wire armor, which makes them lighter and a preferred choice for projects where weight is a factor, such as power distribution in industrial settings.

Both types offer protection against mechanical damage, but the choice depends on the specific requirements of the installation.

-

Is an Armored cable necessary for all outdoor electrical installations?

No, Armored cable isn’t strictly necessary for all outdoor electrical installations, but it’s highly recommended for most. This is due to its durability and protection against environmental hazards. It’s ideal for areas exposed to potential mechanical damage or where extra protection is needed.

-

Can Armored cable be used underground?

Yes, Armored cable is specifically designed for underground installations. Its robust construction protects against moisture, soil corrosion, and physical damage, making it a safe choice for direct burial.

-

What are the legal requirements for installing Armored cable in Vietnam?

In Vietnam, electrical cable installation must comply with several important technical standards:

- TCVN 9208:2012: This standard specifically regulates the installation of cables and electrical conductors in construction projects and is the most important reference. It outlines requirements for safety distances, installation methods, cable protection, and many other technical parameters.

- TCVN 9207:2012: Regulates the placement of electrical conductors in residential and public buildings.

- TCVN 7447 (equivalent to IEC 60364): Governs low-voltage electrical installation systems, including specific requirements for the selection and installation of electrical equipment.

- QCVN 12:2014/BXD: National technical regulation on electrical systems in buildings and public facilities.

Electrical cables also need to meet material and construction requirements according to:

- TCVN 5935 (IEC 60502): For PVC-jacketed electrical cables.

- TCVN 6610 (IEC 60227): For XLPE-insulated electrical cables.

Important criteria include:

- Mechanical strength: Cables must withstand tension, bending, and other physical impacts during installation and use.

- Insulation properties: Ensuring insulation resistance meets standards and doesn’t degrade quickly.

- Fire resistance: Cable jackets need to be flame retardant and shouldn’t produce toxic smoke in case of fire.

Electrical cable installation work must strictly comply with electrical safety regulations as per Circular No. 31/2014/TT-BCT of the Ministry of Industry and Trade on “National Technical Regulations on Electrical Safety.”

Regarding environmental protection, construction must minimize its impact on the surrounding environment, especially for underground cable or high-voltage line installation projects. Waste materials from the installation process must be collected and processed according to regulations.

-

How do you cut Armored cable?

While you can use a few different tools to cut Armored cable, such as side cutters or a hacksaw, the best option is to use dedicated cable cutters specifically designed for the task.

Before cutting the cable, you should accurately measure the required cable length and mark the outer sheath at the cutting point. Then, adjust the cutters’ blade depth correctly to allow it to cut through the armor. You should position the cable in the cutters’ wire guide and align it with the cutting point you marked. Secure it in place and then carefully cut.

-

Do I need an armored cable for outdoor lights?

Using Armored cable for outdoor lights is highly recommended. Outdoor lighting installations are exposed to various environmental factors such as rain, snow, and extreme temperatures, which can compromise the safety and functionality of electrical wiring.6 Armored cable will provide optimal protection.

About Servo Dynamics Engineering – Authorized Distributor of Belden in Vietnam

Are you looking for high-quality and reliable connectivity solutions in Vietnam? Servo Dynamics Engineering is the partner you need! We are proud to be the official authorized distributor of Belden in Vietnam, bringing world-leading cable and connectivity solutions to our customers.

With years of experience in engineering and automation, Servo Dynamics Engineering not only provides a diverse range of Belden products like network cables, industrial cables, audio/video cables, and specialized connectivity solutions but also supports you in choosing the most suitable products. We ensure optimal performance and superior durability for every project. Our partnership with Belden – a globally renowned brand for quality and innovation – reinforces our commitment to delivering reliable connectivity solutions that help your business operate smoothly and efficiently.

Tiếng Việt

Tiếng Việt