Consulting, Industrial Automation

OT in Data Centers: What It Is and Why It Matters

Ever wondered how massive data centers manage to run smoothly 24/7? A crucial part of that is OT (Operational Technology). It may sound complex, but OT plays a crucial role in maintaining the stability and security of physical systems.

What is OT (Operational Technology)?

Operational Technology (OT) refers to the hardware and software systems that monitor and control physical devices and processes. You’ll often find it in industrial settings like manufacturing, energy, and transportation. Think of it as the “brain” that tells machines how to operate. Operational Technology is fundamentally different from IT (Information Technology), which focuses on data and business systems.

What is Operational Technology (OT) in Data Centers?

In data centers, Operational Technology (OT) refers to the systems that monitor and control the physical infrastructure and processes, ensuring the data center stays functional and online. These are separate from the IT systems that handle information and data processing.

OT networks and systems in data centers are specialized industrial control systems. They help manage and control crucial functions like:

- Power Distribution: Keeping the electricity flowing steadily.

- Cooling Systems: Maintaining the ideal temperature for equipment.

- Physical Security: Managing access control and surveillance cameras.

These Operational Technology networks are typically isolated from IT networks for enhanced security. They use specialized communication protocols and often have backup systems to ensure maximum stability.

More specifically, Operational Technology in a data center includes:

- Building Management Systems (BMS): These control power sources (like UPS, PDUs, and generators) and cooling systems (HVAC).

- Physical Security: This manages systems like access control (keycards, biometrics), video surveillance, and alarm systems.

- Environmental Control: Operational Technology systems monitor and adjust factors like temperature, humidity, and airflow to create the perfect conditions for IT equipment.

Key Differences Between OT and IT in a Data Center

| Criterion | IT (Information Technology) | OT (Operational Technology) |

| Focus | Data and information | Physical environment and equipment |

| Priorities | Agility and scalability | Reliability and longevity |

| Speed | Handles large volumes of data | Requires real-time processing and control |

Today, IT and OT are increasingly coming together in data centers. This convergence leads to greater efficiency, real-time monitoring, and predictive maintenance. However, it also means careful consideration of security and functionality is essential.

How Do OT Networks in Data Centers Differ from Other OT Systems?

OT networks in data centers are unique because many other Operational Technology systems operate critical industrial infrastructure (like factories or power grids). Data centers aren’t typically seen as industrial infrastructure but rather as essential information infrastructure.

In both types of infrastructure, worker safety comes first, especially in data center areas dealing with high-voltage electricity or fire suppression. However, in data centers, worker safety risks are generally more contained than in industrial environments. Instead, the biggest priority for data centers is ensuring the reliability of their core functions, keeping that information infrastructure consistently running.

Key Infrastructure Components in Data Centers and Their Impact on Uptime

- Building Management System (BMS): This monitors temperature, humidity, and airflow. Cyber risks to the BMS can lead to unauthorized access, manipulation, or disruption, causing downtime or equipment damage.

- Electrical Management System (EMS): The EMS manages power distribution. Cyberattacks on the EMS can cause power outages, data loss, service interruptions, and even damage to electrical hardware.

- Security Management (SEC): This is responsible for overall physical security, including access controls and video surveillance. Cyber risks to the SEC could allow intruders unauthorized physical access or disable security systems.

- Data Center Infrastructure Management (DCIM): DCIM optimizes data center management by monitoring, analyzing, and controlling every aspect of the infrastructure. Any breach of the DCIM poses a very high risk, as it controls so much and could potentially shut down the entire center.

Rockwell Automation: Driving Efficiency, Resiliency, and Sustainability for Data Centers

As the world’s largest company dedicated to industrial automation and digital transformation, Rockwell Automation understands the complex challenges you face. Together with their trusted PartnerNetwork™, Rockwell Automation offers comprehensive solutions to help you build a data center that’s not just more efficient, resilient, and sustainable, but also achieves the 99.999% uptime goal your customers demand.

Rockwell Automation Solutions for Your Mission-Critical Infrastructure:

- Water Management: Optimize water use to save energy and meet sustainability goals.

- IT/ OT Network Monitoring: Combine IT and OT data to optimize operations and meet uptime demands.

- Thermal Optimization: Install durable, industrial-grade controls for consistent cooling.

- Server Room Operations: Use cloud-based analytics and AI for predictive maintenance. Autonomous Mobile Robots (AMR) can also automate tasks.

- OT Cybersecurity: Build a comprehensive security zone with multi-factor authentication and countermeasures, adhering to the NIST Cybersecurity Framework.

- Energy Infrastructure and Guidance: Smart power systems help monitor and measure power consumption, reducing costs and increasing safety.

- Advanced Integrated Facility: Connect smart devices, processes, and technologies to improve overall performance.

- Building Automation: Monitor and control critical environmental conditions to ensure quality, compliance, and increased uptime.

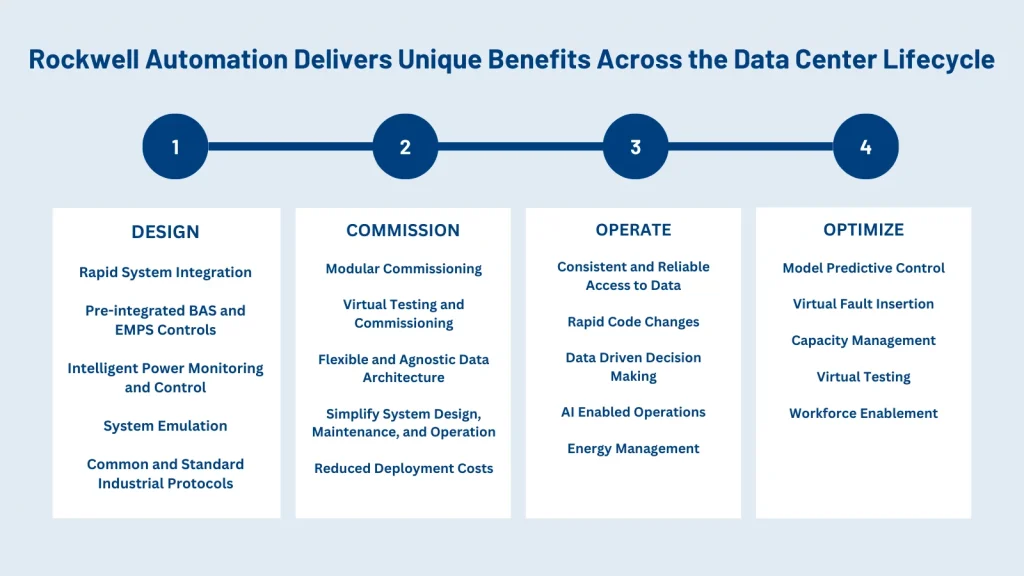

Unique Benefits of Rockwell Automation Across the Data Center Lifecycle:

- Design: Rapid system integration, intelligent power monitoring, and system emulation.

- Commission: Modular commissioning, virtual testing, and flexible data architecture.

- Operate: Consistent data access, rapid code changes, and AI-enabled operations.

- Optimize: Model predictive control, capacity management, and workforce enablement.

Why Partner with Rockwell Automation?

- Industrial-Grade Solutions: Rockwell Automation develops solutions designed for high-capacity, heavy-duty, and extreme environments, helping maintain 99.999% uptime. Their products adhere to strict regulatory standards for safety and environmental protection.

- Global Distribution Network: Rockwell Automation’s global network of authorized distributors provides local installation and service support.

- Speed Time to Market: With their expertise, Rockwell Automation and PartnerNetwork™ help you reduce the timeline for building new or expanding existing data center facilities.

Enhance Your Data Center’s:

- Sustainability: Optimize water and power usage through monitoring, analytics, and AI.

- Operations: Integrate cloud-based analytics and AI for predictive maintenance; use robotics to improve response times.

- Resiliency: Ensure native security down to the device level and protect power systems through Operational Technology network security.

Achieved Results:

A major hyperscaler and global leader in internet and data services sought a turnkey Building Management System (BMS) for a mission-critical, 132,506-square-foot greenfield data center in the U.S. Pacific Northwest.

Challenge: Deliver a standardized, integrated BMS hardware and software solution for all systems, from water processing and fuel to electrical distribution and HVAC units.

Solution: Utilized FactoryTalk® View Site Edition, FactoryTalk® Historian, and FactoryTalk® VantagePoint for comprehensive, accurate, and real-time operational insights. Redundant ControlLogix® controller systems provided fast performance and high capacity.

Results: Standardized system configurations, maximized robust backup with redundant design, enabled no-shutdown preventive maintenance with built-in online testing, allowed phased expansion with a modular architecture, and achieved 99.9999% sustained uptime reliability.

Introduction to Rockwell Automation

Rockwell Automation is the world’s largest company dedicated to industrial automation and digital transformation. With a strong commitment to helping industries operate more efficiently, intelligently, and sustainably, Rockwell offers a wide range of advanced solutions—from hardware and software to services and technical expertise.

Their technologies help businesses connect, optimize, and protect their operations, enabling higher productivity, reduced risks, and greater flexibility to adapt to changing market demands. Rockwell Automation is a global leader in shaping the future of manufacturing and industrial innovation.

About Servo Dynamics Engineering – Authorized Distributor of Rockwell Automation in Vietnam

Servo Dynamics Engineering proudly stands as the authorized distributor of Rockwell Automation in Vietnam, bringing world-leading industrial automation and Operational Technology (OT) solutions to the local market. With extensive experience and deep expertise, Servo Dynamics Engineering is committed to delivering high-quality products, services, and technical support from Rockwell Automation. Our goal is to help Vietnamese businesses optimize their operations, enhance efficiency, and achieve smarter production and operational targets. We are always ready to accompany our customers on their digital transformation journey and in building sustainable infrastructure.

Tiếng Việt

Tiếng Việt