Consulting, Industrial Automation, News

What is a SCADA System and How Does It Work?

SCADA is a crucial system in the manufacturing and infrastructure sectors. So, what is SCADA, and how does it work? Let’s explore SCADA application systems and why they are considered essential in smart factories.

What is SCADA?

SCADA is an acronym for ” Supervisory Control and Data Acquisition” and is pronounced “Skada”, translated directly into Japanese, “monitoring control and data acquisition”, and it is actually one of the monitoring control systems with the function as it is in this word.

SCADA accumulates and analyzes data while monitoring and controlling data sent from various devices and sensors. In addition to these features, alarms and security features may also be included. In addition, some data collected and accumulated is displayed is easy-to-understand graphics, enabling intuitive monitoring.

What are the components of SCADA?

Field Devices: Includes sensors, actuators, PLCs, RTUs, which directly interact with processes to gather data and execute control commands.

Communication Network: The network and communication protocols that transmit data between field devices and the SCADA control center.

SCADA Control Center (Master Station):

- SCADA Server: The main system running SCADA software, processing data, and managing the system.

- Human-Machine Interface (HMI): Provides an intuitive interface for operators to monitor and control the system.

- Historian System: Stores historical system data for analysis and reporting.

How SCADA systems work

The basic operating principle of the SCADA (Supervisory Control and Data Acquisition) system revolves around remote data collection, transmission to a central system, monitoring, and allowing operators to issue control commands. Below are the key steps in SCADA’s operation:

- Data Collection: Field devices (sensors, PLCs/RTUs) measure and collect data from physical processes.

- Communication: This data is transmitted via industrial communication protocols to the SCADA server.

- Monitoring: SCADA software processes and displays data visually on the HMI interface while detecting and alerting about incidents.

- Control: Operators or automated systems send control commands from the HMI through the SCADA server to PLCs/RTUs, which then act on field devices.

- Data Storage and Analysis: The collected data is stored in a database for trend analysis, reporting, and optimization support.

Role of SCADA

So what role does SCADA play in the entire embedded facility?

In a nutshell, it is the role of “visualizing the site and managing the entire facility”. While it may seem obvious and not a special feature, there has never been a system that can simultaneously visualize and manage the entire facility. There was a control system called DCS consisting of dedicated hardware, which is different from SCADA’s role because it was a distributed monitoring system divided by equipment.

In order to perform this role of data acquisition and management, all equipment must be connected so that it can communicate with the system. Therefore, SCADA typically establishes network and external communication between the devices it configures.

The importance of SCADA lies in “visualization through easy-to-understand display” and “collective management of the entire facility”. It has the role of aggregating data received from each device and delivering it to people.

This is in agreement with the role necessary for the smartening of factories, which have been advancing in the manufacturing field of each country in recent years. In smart factories and smart factories, it is ideal that all sensors and equipment are connected to the network, and the data obtained by them should be visualized and managed collectively. SCADA is a system that plays this very role, so if it is incorporated into a smart factory, it will have a very important role.

A system with SCADA built-in

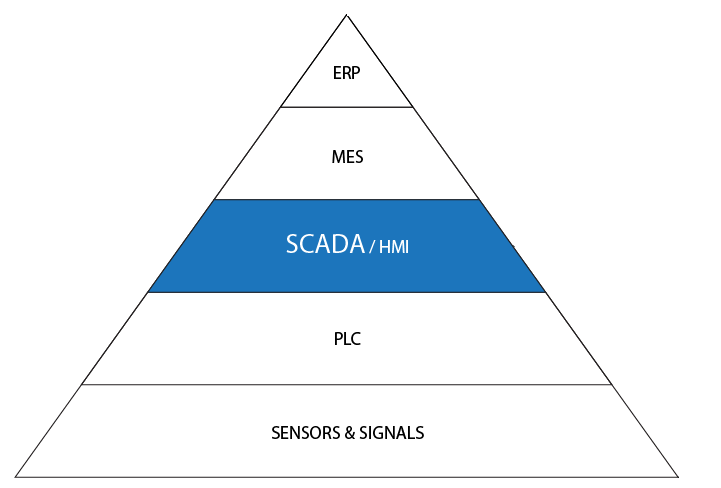

SCADA is a data collection system with the primary purpose of analyzing and displaying the acquired data. It would not have the ability to control equipment. Therefore, in order to control based on the acquired data, it is necessary to use it in cooperation with another control device or system. For example, in the manufacturing and infrastructure businesses, a five-tiered model may be built:

Five layers working with SCADA

- Operating equipment

It is the layer that directly performs the physical process and can be said to be the fingertip of the entire equipment. Includes equipment such as motors and pumps.

- Sensor / control

This is the layer that performs sensing and control. In conventional control systems, control is performed here and it is monitored by the human eye. Devices such as sensors, PLCs (sequencers), and RTUs (remote terminal units) fall into this layer.

- Monitoring and data collection

This layer monitors and collects data on the operation and control status of equipment. SCADA is located here.

- Operation status management

This layer manages the operating status of production lines and equipment. It is a part that needs to be linked with production control, process control, raw material arrival, product shipment, etc. Includes MES (Manufacturing Execution System) and MOM (Manufacturing Operations Management).

- Management plan

And the layer of this management plan is located at the top. ERP (Enterprise Resource Planning) corresponds to this part.

SCADA connects the middle between the field side and the management side

In this way, SCADA is located at the halfway point where information from equipment and sensors operated directly in the field is received and bridged to the layers that manage and execute it.

If you think of the entire facility as an organization like a company, it can be said that you are in charge of the front line of the field. SCADA acts like a field supervisor on a system.

SCADA, IIoT, and Edge Computing

Given SCADA’s system for collecting data at the forefront of the field, it should be able to operate as an IoT (IIoT) software platform in the industrial field. In particular, there is a connection with edge computing?

What will change and evolve by connecting SCADA with edge computing?

Add speed to systems with SCADA embedded

Edge computing improves equipment response speed by processing data at the forefront of the field.

On the other hand, SCADA plays a role in extracting and processing data from devices and sensors. This means that you already have the ability to process the data on the edge side. Then, just by connecting SCADA to the cloud, SCADA can function as edge computing.

In this way, SCADA is a system that can gain its benefits and exert even more power by linking it with edge computing.

Take the Smart Factory One Step Ahead

Smart factories, can be said to be the next-generation manufacturing industry realized by the development of the cloud and IIoT (Industrial IoT, IoT for the industrial field).

In a typical smart factory, data is collected from sensors installed in various devices and sent to the cloud, which makes it possible to check the operating status from anywhere. This is one of the great advantages of smart factories. SCADA is a suitable system for collecting and controlling and monitoring that data.

However, as the number of smart factories that actually operate has increased, a certain issue has surfaced. It’s the speed of data processing. When it comes to sending and receiving huge amounts of data from any device to the cloud on a network and processing it, traffic issues arise.

When data is sent back and forth from the site to the cloud and from the cloud to the site, there is a time lag of hundreds of milliseconds to several seconds. This time lag is a challenge for smart factories.

At the cutting edge of the manufacturing industry, smart factories are often equipped with high-performance equipment to enable precise and high-speed operation. Despite the existence of such sophisticated equipment, if there is a time lag in data transmission/reception and processing, the performance of the equipment cannot be fully utilized. Even with a minute time lag, if it accumulates, it will cause waste due to a decrease in the cycle.

Edge computing is the solution to these challenges. Instead of sending and receiving all data to the cloud, it processes data in near real-time near the site, improving device performance. SCADA can also play a decentralized role by linking with edge computing while collecting data.

In this way, by operating a combination of IIoT, SCADA, and edge computing, smart factories can evolve to the next level.

Applications of SCADA

SCADA has numerous applications across various industries, including:

- Power Industry: Monitoring and controlling power grids (substations, transmission, and distribution lines).

- Oil and Gas Industry: Managing and controlling extraction, transportation (pipelines), and processing (refineries, petrochemicals).

- Water and Wastewater Treatment: Monitoring and controlling water supply systems, wastewater treatment, reservoir, and dam management.

- Transportation Industry: Traffic light control systems, railway, highway, and airport monitoring and management.

- Manufacturing Industry: Automation and monitoring of production lines, industrial robot management, quality control.

- Chemical Industry: Monitoring and controlling complex chemical processes, ensuring safety and efficiency.

- Food and Beverage Industry: Managing production processes, ensuring hygiene and product quality.

- Smart Buildings and Infrastructure: Controlling HVAC (heating, ventilation, and air conditioning) systems, lighting, security, and energy management.

- Renewable Energy: Monitoring and controlling wind farms and solar power plants.

Important Considerations When Using SCADA

Implementing and using a SCADA system requires attention to multiple factors to ensure efficiency, security, and reliability. Here are some key considerations:

- Security: This is the top priority. SCADA systems often control critical infrastructure, so robust security measures must be in place to prevent cyber-attacks.

- Scalability: The system should be scalable to accommodate future growth in data points, devices, and functionalities.

- Compatibility: Ensure that the SCADA system can communicate with other devices and systems (PLCs, RTUs from various manufacturers, MES, ERP) via standard protocols.

- Real-time Performance: The system must collect, process, and display data swiftly so that operators can make timely decisions.

- User-friendly HMI: The Human-Machine Interface (HMI) should be intuitive, easy to use, and provide clear information for operators.

- Data Storage and Analysis: The ability to store historical data comprehensively and offer powerful analytical tools is crucial for performance monitoring, trend detection, and process optimization.

Top 5 SCADA companies

There are many reputable SCADA software and system providers in the global market. Below are some of the leading companies:

Rockwell Automation

FactoryTalk View by Rockwell Automation is a powerful SCADA platform, particularly suited for Allen-Bradley control systems. This software supports detailed data collection and analysis, enabling remote monitoring and control. With high visualization capabilities, FactoryTalk View helps businesses optimize operations and enhance production efficiency.

Siemens

Siemens is a leading SCADA solution provider with its WinCC software. This system offers real-time monitoring and control of production processes and integrates seamlessly with Siemens PLCs (S7-1200, S7-1500, etc.). WinCC provides an intuitive interface and flexible scalability, from single workstations to large-scale SCADA systems, making it suitable for various industries.

Schneider Electric

Schneider Electric offers Wonderware InTouch, a well-known SCADA software with a user-friendly graphical interface and strong connectivity with various devices. Additionally, Schneider’s EcoStruxure SCADA platform supports monitoring in industries such as energy, water, oil and gas, and more.

AVEVA (Wonderware)

AVEVA develops the Wonderware System Platform, a powerful SCADA solution for large-scale system monitoring and control. With AI and Big Data integration, AVEVA SCADA enables businesses to optimize operations and perform in-depth data analysis to improve production efficiency.

Mitsubishi Electric

Mitsubishi Electric’s SCADA system is a comprehensive data acquisition and monitoring solution that integrates with PLC programming devices for effective automation management. This advanced software optimizes data center operations and enhances operational performance.

Servo Dynamics – Official Distributor of Rockwell Automation in Vietnam

Servo Dynamics is the official distributor of Rockwell Automation solutions in Vietnam. With extensive experience and a highly skilled technical team, Servo Dynamics is committed to delivering advanced and robust SCADA systems from Rockwell Automation. These solutions help businesses in Vietnam optimize production processes, improve operational efficiency, and achieve significant advancements in the Industry 4.0 era.

Tiếng Việt

Tiếng Việt