Everything is packaged, from consumer goods to food and pharmaceutical products. The Baumer Group has been a competent partner to over 3000 machine manufacturers worldwide in the packaging industry for many years and offers a broad portfolio of sensor solutions, encoders, smart vision sensors, cameras and process sensors. Our sensors enable maximum process safety and flexibility with regard to the product to be packaged and the packaging itself.

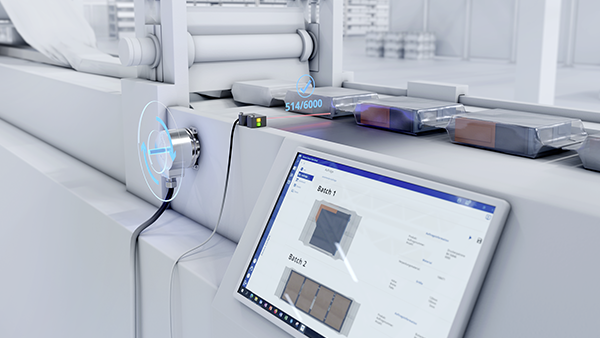

Baumer sensors also support digital transformation in the packaging industry. Standardized digital communication interfaces, such as IO-Link or fieldbus-based interfaces, can be used to process information in addition to the measured values in order to further optimize the processes.

They reduce

- complexity

- time to market

- engineering effort

We offer sensors

- with high performance reserve

- in a one-box design

- in all sensor technologies with standard interfaces

You increase

- the availability of the system

- the flexibility of packaging material and products

- the machine performance

We offer sensors

- with short response times and high sampling rates

- with extremely reliable detection and precise positioning

- with quick and easy parameterization via IO-Link

You receive

- a solution offer for all technologies

- recommendations for process optimization

We offer

- expertise across various technologies

- in-depth sensor know-how

- valuable data and information via standard digital interfaces

You benefit from

- our one-stop shop

- our packaging competence on site

- a reliable partnership

We offer

- a broad portfolio of sensor solutions

- 39 subsidiaries in 19 countries

- long-term product availability

All sensor technologies and areas of expertise from a single source

Keeping an eye on your packaging machines

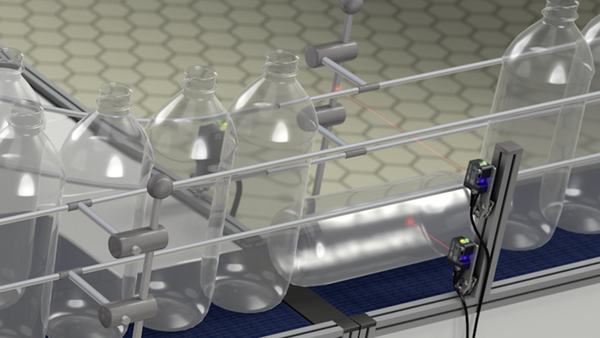

Robust sensors in washdown and hygienic design are crucial for safe packaging of food and beverages as well as cleaning processes.

Forming, filling and sealing machines

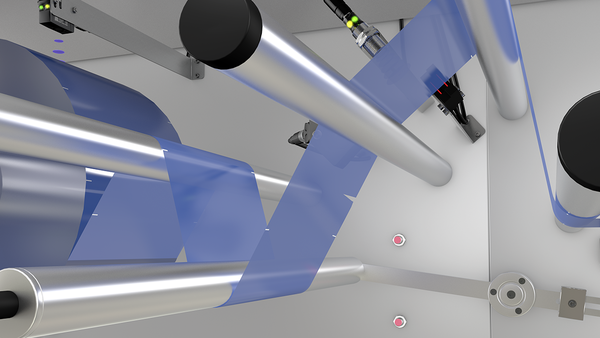

The high variety of packaging and use of challenging materials in forming, filling and sealing machines, such as transparent and high-gloss foil, require reliable sensors with a high performance reserve.

Labeling machines

Precise and reliable sensor solutions are essential in highly dynamic labeling processes and help manufacturers to protect their brand and products from tampering and falsification.

Application examples

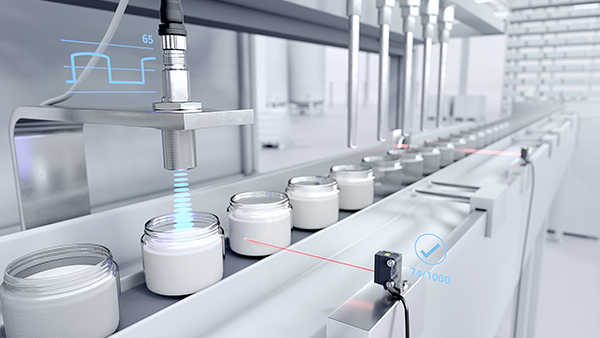

High performance reserves and short response times of our optical sensors guarantee flexibility and operational reliability, particularly for demanding objects.

Whether inductive, ultrasonic or magnetic sensors we offer the optimal sensor solutions for highly dynamic packaging processes, even of extremely thin, sustainable packaging materials.

Serialization, tracking & tracing and tamper-proof labels are becoming increasingly important. We offer a product portfolio of high performance cameras as easy-to-use sensor solutions to ensure a specific quality.

Tiếng Việt

Tiếng Việt