News, Consulting, Solutions

Industrial Communication Cables: What Are They? Classification, Structure & Detailed Applications

Industrial Communication Cable is the indispensable backbone component in every modern automation system and process control network. Specifically designed to operate reliably in the harsh environments of manufacturing facilities, these cables ensure that data transmission between control and monitoring equipment occurs quickly, stably, and without interference.

What Are Industrial Communication Cables?

Communication Cable Concept

An Industrial Communication Cable is a specialized cable type, fundamentally different from standard network (LAN) cables. Its main function is to transmit data (digital signals) between automation devices such as PLCs (Programmable Logic Controllers), HMIs (Human-Machine Interfaces), sensors, actuators, and industrial computers.

They are engineered to resist common destructive elements in industrial settings, including: electromagnetic interference (EMI), vibration, high/low temperatures, humidity, oil and grease, and corrosive chemicals.

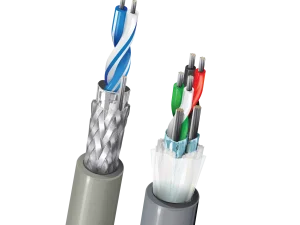

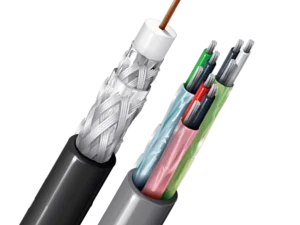

Basic Structure of Communication Cables

The structure of an industrial communication cable is optimized to protect the signal, typically comprising four main components:

- Conductor

- Material: Typically copper (bare copper, tinned copper) or optical fiber (for fiber optic cables).

- Purpose: Transmits electrical or light signals. In industrial environments, the core often has a stranded structure to increase flexibility and resistance to bending during installation or robot operation.

- Insulation

- Material: PVC, high-density Polyethylene (PE) or Polypropylene (PP).

- Purpose: Prevents signal leakage between cores and ensures signal integrity.

- Shielding

- Features: This is the most crucial part. Industrial cables may use a Foil Shield to suppress high-frequency noise, a Braid Shield to combat low-frequency noise, or a combination of both (Overall Shield/Individual Shielded Pairs).

- Purpose: Protects the internal signal from strong electromagnetic noise sources emanating from motors, Variable Frequency Drives (VFDs), and high-voltage power lines.

- Outer Jacket

- Material: Usually PVC, TPE (Thermoplastic Elastomer), PUR (Polyurethane) or LSZH (Low Smoke Zero Halogen).

- Purpose: Protects the cable from mechanical damage, abrasion, UV rays, oil, chemicals, and extreme temperatures.

What are the most common types of communication cables?

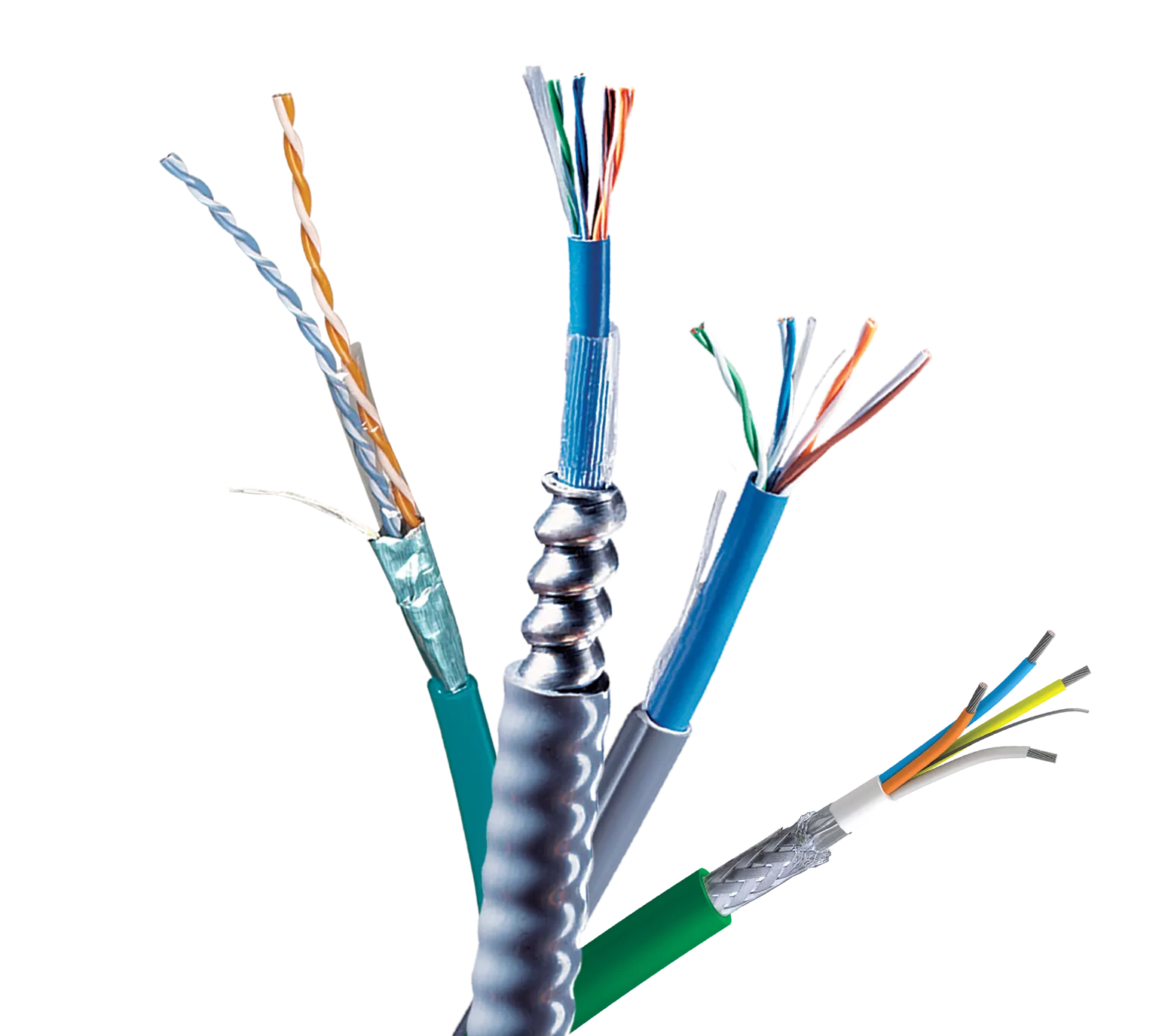

In the industrial sector, the most popular communication cables include:

- Twisted Pair Cable: The most common type (RS485, Fieldbus, Industrial Ethernet). Pairs of wires are twisted together to cancel out electromagnetic interference and crosstalk.

- Shielded Cable: Uses Shielding layers (F/UTP, S/FTP) to protect the signal, which is absolutely essential in the factory environment.

- Fiber Optic Cable: Uses glass/plastic fibers to transmit signals via light, offering complete immunity to electromagnetic interference, high speed, and long transmission distances.

Why Does Industrial Communication Require Specialized Cables?

Standard communication cables (like office network cables) cannot meet the strict requirements of the production environment.

Noise Immunity in the Factory Environment

Manufacturing plants contain numerous sources of electromagnetic interference (EMI), including:

- Large motors and generators.

- VFDs (Variable Frequency Drives) which generate high-frequency noise.

- Welding equipment, cutting machines.

Specialized cables are equipped with thick shielding layers and precise twisting techniques to ensure the signal is not distorted, allowing the system to operate continuously without interruption.

Ensuring Stable Signal Transmission Speed

In real-time control systems, latency is the enemy. Industrial cables are designed with tightly controlled impedance and capacitance to maintain high and consistent signal transmission speeds, which is particularly important for high-speed protocols like Industrial Ethernet.

Mechanical Durability – Heat Resistance – Oil Resistance

Industrial cables must withstand:

- Vibration: Caused by large operating machinery.

- Temperature: Operation near furnaces, or in hot electrical cabinets.

- Chemicals: Exposure to cooling oils, solvents, and cleaning agents.

Special jackets made from TPE or PUR materials help the cables resist abrasion, extreme temperatures, and degradation upon contact with oil, extending their lifespan and reducing maintenance costs.

Common Types of Industrial Communication Cables

RS485 Cable – The Most Popular Industrial Communication Standard

RS485 is a very common multi-drop Serial Communication standard. RS485 cables are typically shielded twisted pair cables with a characteristic impedance of 120 Ohm, allowing stable data transmission over very long distances (up to 1200 meters). It is widely used for protocols like Modbus RTU.

Industrial Ethernet Cable – Cat5e, Cat6, U/UTP

Industrial Ethernet is the application of the Ethernet standard (IEEE 802.3) to the industrial environment. Industrial Ethernet cables typically use a Cat5e or Cat6 structure but feature a more robust jacket (oil-resistant, flame-retardant, high noise immunity) to achieve reliable 100 Mbps or 1 Gbps performance in the factory.

Measurement Signal Cable (Sensor/Encoder)

These cables are responsible for transmitting high-precision analog or digital signals from sensors and encoders back to the PLC or controller. They require extremely effective shielding to prevent signal corruption from noise, ensuring the accuracy of the measurement and control processes.

Fieldbus Cable (Profibus, Modbus, CAN, DeviceNet)

Fieldbus is a group of communication standards for field devices. Each standard requires a specific cable type with specific electrical parameters:

- PROFIBUS DP: Typically a purple twisted pair cable, 150 Ohm impedance.

- CAN Bus/DeviceNet: Requires a cable with 120 Ohm impedance.

- FOUNDATION Fieldbus: Twisted pair cable, 100 Ohm impedance, often used in process control systems.

Industrial Fiber Optic Cable

Industrial fiber optic cables are used when requirements include:

- Absolute immunity to electromagnetic interference: Necessary in high-voltage areas.

- Extremely high transmission speeds: Up to 10 Gbps or more.

- Very long transmission distances: Exceeding the 100-meter limit of copper cables.

What is an Industrial Communication Network?

Industrial Communication Network Concept

An industrial communication network is a system that links high-level control devices (Control Level) with field devices (Field Level) through specialized protocols and cables. The goal is to exchange data, control commands, and monitoring information automatically and synchronously.

Role in Automation & SCADA

- Automation: The network allows the PLC to command actuators and receive data from sensors in real-time, forming the foundation of all automated processes.

- SCADA System (Supervisory Control and Data Acquisition): The communication network transmits data from the field level up to the monitoring server, enabling operators to track, analyze, and control the entire production process remotely.

Components of an Industrial Communication Network

A typical industrial communication network includes:

- Controllers: PLC, industrial PC.

- Field Devices: Sensors, actuators, valves, meters.

- Interfaces: HMI (touch screen), computer.

- Converters/Connectivity: Industrial switches, Media Converters, Gateways.

- Communication Cables: Specialized cables (Ethernet, RS485, Fieldbus) connecting these components.

Current Industrial Communication Types

Serial Communication (RS232/422/485)

This is a long-standing, simple, and reliable method of data transmission. Data is transmitted bit by bit. RS485 is the most common standard for industrial communication due to its long-distance transmission capability and multi-drop connectivity.

Industrial Ethernet Communication

Uses the familiar TCP/IP network structure but is enhanced to ensure the determinism and high speed required for real-time control. Notable protocols include PROFINET, EtherNet/IP, and Modbus TCP.

Fieldbus Communication

This is an intermediate network generation between Serial and Ethernet, providing distributed control capabilities and is an economical choice for the field device level (e.g., PROFIBUS, CAN Bus).

Wireless Industrial Communication

Becoming increasingly popular for connecting devices that are difficult to wire or are mobile. Includes industrial Wi-Fi, WirelessHART, and cellular technologies (5G) for data collection (IIoT – Industrial Internet of Things).

Applications of Industrial Communication Cables

Production Lines and Automation

Cables are used to connect central controllers to industrial robots, conveyor belts, and automated workstations.

PLC – HMI – Sensor Connection

This is the most basic application, where cables transmit status data from hundreds of sensors to the PLC and transmit control commands from the PLC to execution devices.

SCADA System

Communication cables are the means to transfer aggregated information from field controllers (PLCs) to the SCADA server for monitoring and data logging.

Machine Control – Industrial Robots

In continuous motion applications (Continuous Flex), specialized industrial cables must have high flex endurance (Flex Cable) to prevent breaking during millions of repetitive cycles of robot movement.

How to Choose the Right Communication Cable

Cable selection must be based on three basic criteria to ensure optimal system performance.

Selection by Communication Standard (RS485 / Ethernet / Fieldbus)

Each communication protocol requires a cable with clearly defined electrical specifications (impedance, capacitance). Using the wrong type of cable can lead to serious signal attenuation and communication errors.

Selection by Installation Environment

This criterion determines the cable’s durability and lifespan:

| Environment | Jacket Requirement |

|---|---|

| High Noise | Dual Shielded Cable (Foil + Braid Shield – SF/UTP or S/FTP) |

| Outdoors/UV Exposure | UV-resistant, moisture-resistant jacket (usually PE or PUR) |

| Oil/Chemical Resistance | Specialized PUR or TPE jacket (e.g., oil-resistant Belden Fieldbus/Ethernet cable) |

| Fire Resistance/LSZH | Low Smoke Zero Halogen jacket, mandatory in public or hazardous areas. |

Quality Note: Reputable brands like Industrial Communication Cable Belden provide specialized solutions tested to meet these stringent harsh conditions, ensuring long-term reliability.

Selection by Technical Specifications

- Conductor Gauge (AWG): Affects transmission distance.

- Resistance (Ohm): Must match the protocol requirements (e.g., 120 Ohm for RS485).

- Transmission Speed & Line Length: The higher the speed, the shorter the maximum line length.

Comparison Table of Industrial Communication Cables

A visual comparison of cable types helps users make quick decisions, while also optimizing Google’s structured data collection capability.

| Cable Type | Common Application | Max Speed | Max Distance | Noise Immunity | Cost |

|---|---|---|---|---|---|

| RS485/Modbus | Sensors, Field Devices, HVAC | Low (10 Mbps) | Very Long (1200 m) | High (Shielded) | Low |

| Fieldbus (Profibus) | Factory Automation, D-I/O | Medium (12 Mbps) | Long (100-1000 m) | High (Shielded) | Medium |

| Industrial Ethernet | PLC, SCADA, IP Cameras | High (100 Mbps – 10 Gbps) | Medium (100 m) | Very High (Industrial Jacket) | Medium/High |

| Fiber Optic | Network Backbone, High Voltage Areas | Very High (> 10 Gbps) | Very Long (> 2 km) | Absolute (EMI Immunity) | High |

Frequently Asked Questions (FAQ)

What is a communication cable?

A communication cable is a specialized cable used to transmit digital data signals between two or more devices, distinct from a control cable that transmits analog signals or power.

What is the RS485 cable used for?

The RS485 cable is used to establish a multi-drop serial communication network, connecting multiple devices (such as temperature sensors, meters) to a central controller (PLC/PC) over long distances.

Is U/UTP cable considered industrial communication cable?

U/UTP (Unshielded/Unshielded Twisted Pair) cable is an unshielded twisted pair cable. It is not recommended for use as an industrial communication cable in environments with high electromagnetic noise. S/FTP or SF/UTP cables (with a shielding layer) are the standard choice.

How do communication cables and control cables differ?

Communication cables transmit digital data at high speeds and require strict noise immunity. Control cables transmit analog signals (4-20mA, 0-10V) or low voltage power to supply power/activate relays and typically have a larger core cross-section.

Can standard data transfer cables be used in a factory?

Standard data transfer cables (e.g., USB cables, HDMI cables) lack the mechanical durability and noise immunity required to withstand the factory environment, and therefore should not be used.

How much does industrial communication cable cost?

The price of industrial communication cable depends on the standard (RS485 is cheaper than Industrial Ethernet), core material (copper is cheaper than fiber optic), and jacket material (LSZH/PUR is more expensive than PVC). To receive an accurate quote, you need to clearly define the standard and installation environment.

Belden’s Industrial Communication Cables: Reliable Performance in Harsh Environments

When it comes to industrial automation and process control, choosing the right communication cable is crucial for ensuring seamless data transmission, minimizing downtime, and maintaining operational efficiency. Belden’s Industrial Communication Cables, including its Fieldbus cables, are engineered to deliver exceptional durability, interference resistance, and long-term reliability in the most demanding environments.

Designed for Harsh Industrial Conditions

Industrial environments present numerous challenges for communication networks, including:

- Extreme Temperatures – Operating efficiently in high-heat or freezing conditions.

- Humidity & Moisture Resistance – Protecting signal integrity in wet or corrosive environments.

- Oil & Chemical Resistance – Preventing cable degradation from industrial fluids.

- Dust & Abrasion Protection – Ensuring long-term durability in rugged settings.

- Electromagnetic Interference (EMI) Shielding – Maintaining stable signal transmission in high-noise environments.

Supporting Key Industrial Protocols

Belden Industrial Communication Cables are compatible with widely used industrial communication protocols, including:

- FOUNDATION Fieldbus – Ensuring real-time communication in process automation.

- PROFIBUS – Used in factory automation and motion control applications.

- DeviceNet & CAN Bus – Supporting industrial networking for controllers, sensors, and actuators.

- Modbus & RS-485 – Enabling reliable serial communication in industrial settings.

- Ethernet-Based Protocols (EtherNet/IP, PROFINET, Modbus TCP) – Providing high-speed data exchange for modern industrial networks.

Fieldbus Cable Product Families

Belden Fieldbus cables are designed to withstand the destructive conditions commonly found in industrial applications, such as temperature extremes, humidity/moisture, dust and oil. Invest in cable with proven performance and reliability to significantly reduce system failures and avoid costly downtime.

Servo Dynamics – An Authorized Distributor of Belden in Vietnam

Servo Dynamics is the official authorized distributor of Belden in Vietnam, bringing customers the world’s leading advanced industrial communication and networking solutions. With a strong reputation and extensive experience, Servo Dynamics is committed to providing high-quality Belden products, along with professional support services, meeting all the needs of Vietnamese businesses in the industrial sector.

Learn more

Tiếng Việt

Tiếng Việt