Sản phẩm mới

Plantwide Safety, Compliance & Productivity

Best-in-Class Safety, Compliance and Productivity

Rockwell Automation has a well-deserved reputation for helping you improve productivity and quality. We’re also the world’s largest safety system provider.

We are the industry leader in safety and compliance, helping reduce injuries and costs while improving productivity throughout your site. Our expertise, experience, and products have established us as the world leader in industrial safety technology, enhancing your business performance with functional safety solutions.

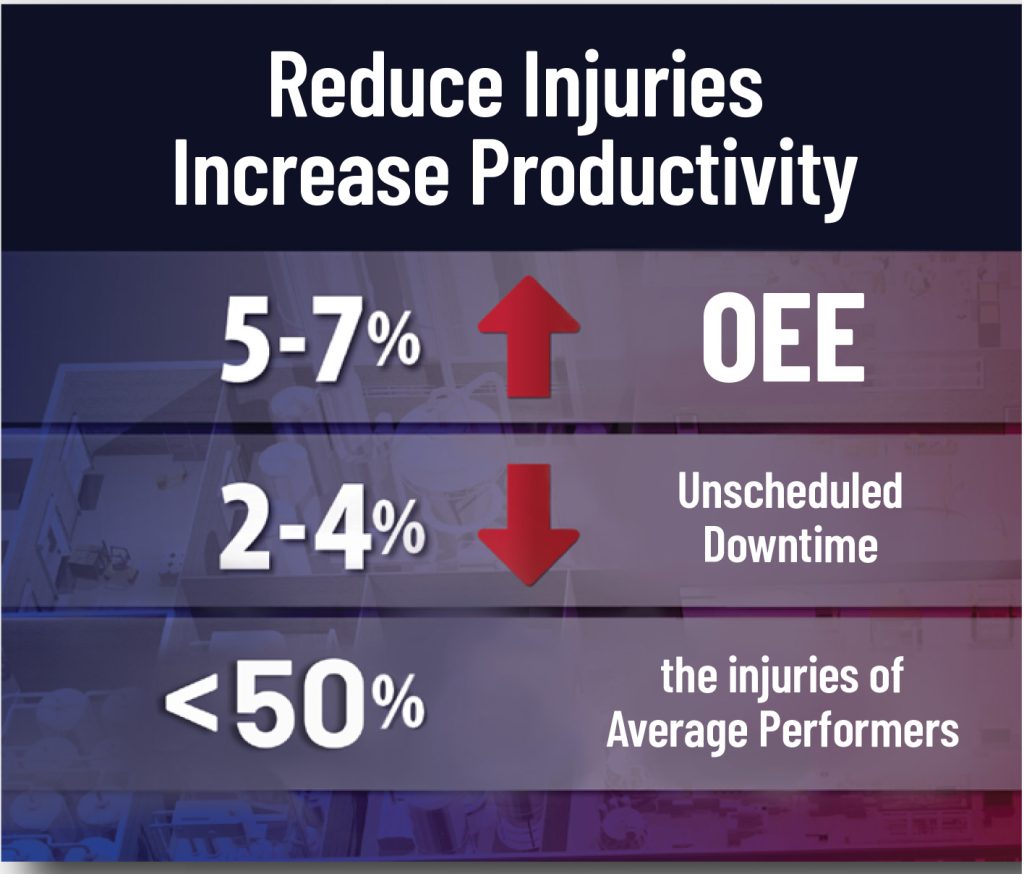

Multiple studies have shown that safety and productivity go hand in hand. These studies identified three key elements separating best-in-class use of technologies that significantly improve both safety and productivity.

Reduce Time to Design, Develop and Deliver Safety Solutions

Rockwell Automation can help improve your performance through formalized risk management practices and technologies to identify and mitigate machine, process, and electrical safety hazards. We provide the industry’s most complete offering of safety services and products, and a suite of tools to help accelerate safety system development and ensure compliance.

Design

- Design Productivity

- Extensible Engineering

- Scalability

- Risk Assessment

- Design for Sustainability

- Global Standards

Develop

- Time to Market

- Supply Chain Efficiency

- Flexible Equipment Models

- Simplified Integration

- Design Optimization

Deliver

- Commissioning

- Global Service & Support

- Reliability & Quality

- Machine Performance

Machinery Safety

Rockwell Automation takes a holistic approach to safety, providing innovative safety solutions that improve the functional operation of machinery – simultaneously helping increase safety, productivity, and reducing waste. Our range of scalable machinery safety solutions, from simple components to large integrated control systems, provides you with the right technology fit for your application.

- Safety/Risk Assessments

- Integrated Safety Controllers

- Intelligent Safety Relays and Timers

- Safety Drives and Motion Control

- Light Curtains, Safety Mats, Edge Guards and other sensors

- Safety Interlocks and Switches

Electrical & Arc Flash Safety

Rockwell Automation provides unique power enclosures which isolate the the fused disconnect switch or circuit breaker from the main control panel. These offerings will protect workers from an arc flash incident and lower the possibility of an arc flash incident occurring at all.

• Arc Flash resistant MCCs

- Instantaneous Maintenance Mode

- Secure Connect

Process Safety

Rockwell Automation has over 40 years of experience in providing process safety solutions and services. Our range of process safety offerings provides scalable solutions to satisfy cost, safety integrity level (SIL 1, 2 and 3), performance, and availability requirements including ESD, F&G, Turbine and Compressor, HIPPS, Combustion Control and CPC

- Safety Assessments

- SIL 1, 2 and 3 Process Safety Systems

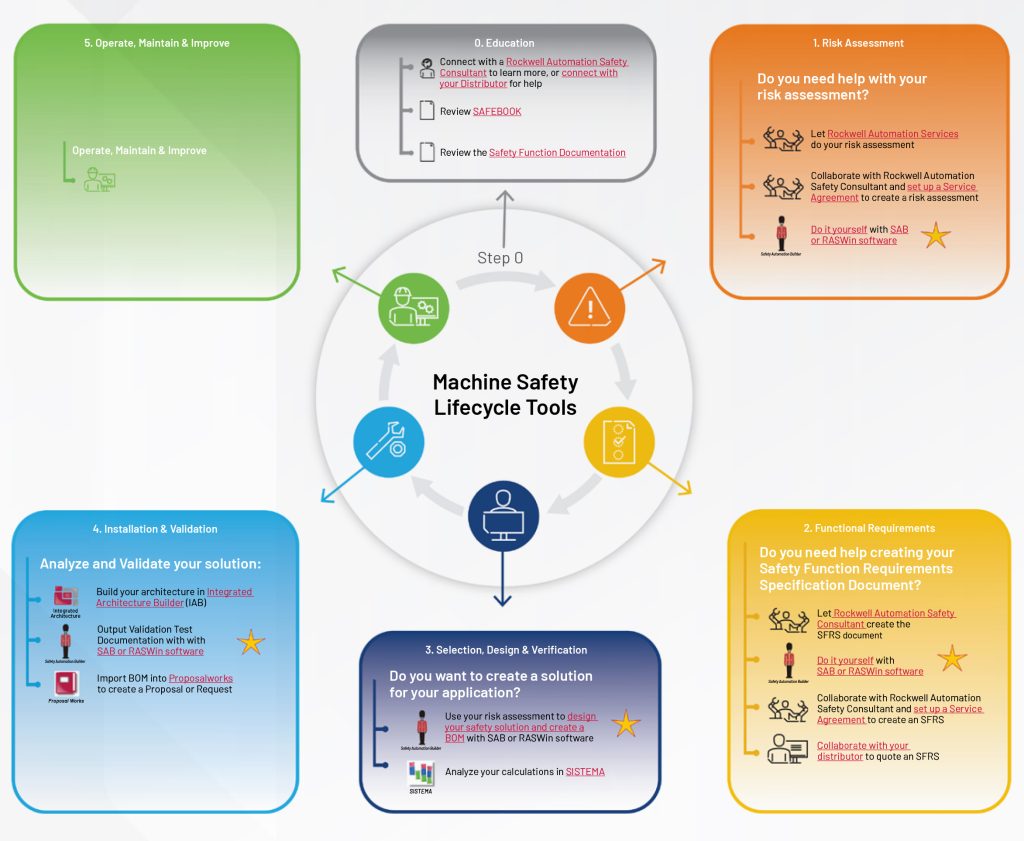

Safety Lifecycle

Using contemporary safety technology and a rigorous Functional Safety Lifecycle approach, you can harness the inherent value of intelligent safety system designs. This approach can help you get machines online faster, reduce design time and costs, and ultimately increase the bottom line.

Before starting your safety implementation, call upon our safety consultants to help you develop a corporate safety program. Develop your competencies through our safety expertise, training and reference documentation.

1. Perform a risk assessment

This phase will identify hazards and estimate the risk associated with them. A risk assessment will determine the required Performance Level (PLr) for safety functions. The specific services involved in a risk assessment include:

- Conformity audits

- Standard safety assessments

- Term-based risk assessments

- Deveopment of a corporate safety program

2. Identifying steps to mitigate risks

Based on the risk assessment results, you can determine the functional safety system’s requirements to mitigate any identified risks. This process considers machine interactions and modes of operation. Use industry-acceptable solutions to evaluate the safeguarding options available.

3. Design and verify the system

Once a system is determined, you can choose its architecture. During this step, you will also document the safety circuit design. Finally, the design is verified to meet all requirements, including software and programming.

4. Install and validate the system

After installing the safety system, you will verify that it operates within the defined parameters and complies with standards. This step may involve bringing specialists on-site who can help perform validation testing and document the process.

5. Maintain and make improvements

A safety system must be monitored and evaluated frequently. You will need to verify that the system requirements operate within specified parameters for production, and make system upgrades and improvements as necessary. After step 5, the cycle repeats itself as you start planning for new functional safety processes to implement.

To help you meet production needs safely and achieve regulatory compliance, we offer a complete portfolio of machine, process and electrical safety solutions. From safety hardware and software to safety services, we can help you develop a safety lifecycle plan to reduce risk while enhancing productivity.

At each phase of the Safety Lifecycle, Rockwell Automation provides tools and expertise to help in your journey to simplify development, improve compliance, and reduce design time and costs including: Safety Automation Builder® (SAB), Safety Function Documents, Safety Integrity Software Tool for Evaluation of Machine Applications (SISTEMA) Library, Safety Accelerator Toolkit and Safety ROI Tool.

Safety System Development Tools

Streamline Safety System Development to Reduce Time and Improve Compliance

The Safety Lifecycle methodology can dramatically reduce safety system development time and improve compliance. This approach is outlined in safety standards and our development tools.

Understand your Return On Investment (ROI) for a safety system, document and manage your progression through the safety lifecycle, develop safety systems, and details of specific safety functions. These tools will help ensure that your systems are compliant and productive.

SISTEMA Performance Level Calculator

The SISTEMA tool automates calculation of the attained Performance Level from the safety-related parts of a machine control system. Data for our machine safety products is now available in the form of a library file to be used with the SISTEMA calculation tool. The combination of the two saves time and provides comprehensive support for safety evaluation to (EN) SO 13849-1 for machine and system designers.

Pre-Engineered Safety Functions

Machine safety functions require multiple elements that include input device, logic device, and output device. Together, they provide a level of protection calculated by Performance Level as outlined in ISO 13849-1.

Built with you in mind, these documented safety functions minimize risk and speed development.

Examples of the information that is provided in our safety functions documents include:

- Set-up and wiring

- Bill of materials

- Wiring schemes

- Configuration

- Verification and validation plan

- Calculation of Performance Level

Safety Automation Builder®

Safety Automation Builder® is a FREE software tool to help simplify machine safety design and validation, and reduce time and costs. Integration with our risk assessment software provides you with consistent, reliable, and documented management of the Functional Safety Lifecycle.

Features of this tool include the ability to:

- Import machine drawings for use in the design process

- Identify hazards and define safety zones

- Identify guarding locations and access points

- Select safety-rated hardware that includes input, logic, and output devices to help maintain compliance and Performance Level

- Design verification

- Create concise reports

- Generate bill of materials (BOM)

- Creation of SISTEMA export file

RASWin Software Tool

RASWin (Risk Assessment Software for Windows) is a subscription-based software tool to develop and maintain machine functional safety documentation. It helps you manage your progression through the safety lifecycle, from definition of hazardous areas and guided selection of corrective measures to reporting and online monitoring tools. The tool organizes information from each step of the safety lifecycle process and includes:

- Ability to link the steps of the safety lifecycle to avoid systematic failures

- Two methods of analysis, task or hazard assessment

- A guide to corrective measures in accordance with ISO standards

- Safety function specifications, Performance Level requirements (PLr) assignment, and PL calculation

- Safety circuit validation tool

- Configurable reporting tool with multiple options

Product Selection Toolbox™ – ProposalWorks™ and Integrated Architecture Builder™

- Our powerful range of product selection and system configuration tools assist you in choosing and applying our product.

- Configure and generate bills of material for NetLinx-based network with Integrated Architecture Builder

- Easy-to-use-Proposal Works interface makes it a snap to determine the exact Allen-Bradley product and service you need and current list pricing

- Software automatically selects the appropriate informational documents, photos, etc.

Integrated Safety Solutions

Our innovative safety products and solutions improve the functional operation of

your machinery while helping to increase personnel safety, efficiency and productivity. We offer one the broadest safety portfolios in the industry to help you achieve both safety and productivity goals in process and discrete manufacturing applications.

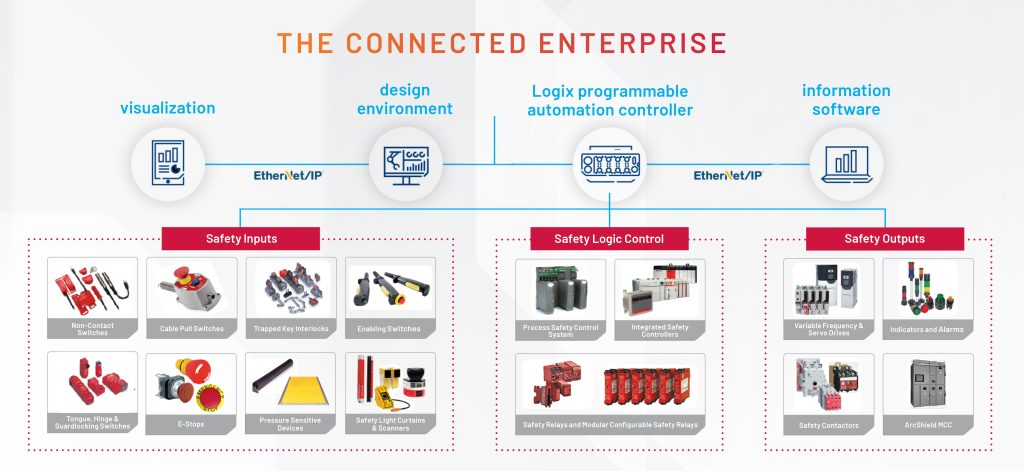

Hardwired safety solutions are being replaced by Smart Safety solutions. Smart Safety solutions reduce wiring requirements, while providing detailed diagnostic data to your design environment, visualization system, information software and GuardLogix® Programmable Automation Controller. Smart Safety solutions enable Smart Machines for use in The Connected Enterprise® and help to increase productivity and minimize downtime while reducing total cost of ownership.

Smart Safety Enables Smart Machines for Smart Manufacturing

A solution incorporating Smart Safety devices enables safety professionals to transform the way they monitor and manage safety. Rockwell Automation provides a complete Smart Safety solution to meet safety requirements, covering safety input devices, safety logic and safety output devices.

Software

The foundation of your industrial digital transformation

Harnessing the power of safety and operational data can substantially improve safety compliance and performance. The Connected Enterprise enables this, empowering safety professionals with a real-time understanding of worker behaviors, machinery compliance, causes of safety shutdowns or stoppages, and safety anomalies and trends.

Getting information to workers is important, but so is getting workers to act on the information. That’s why incorporating safety-system information into daily operations is critical. For example, analytics should be included in daily production meetings, and standard procedures should be developed for collecting, analyzing and interpreting data.

With these elements in place, safety professionals can monitor and refine all aspects of safety in a Connected Enterprise as part of a continuous-improvement program. This could include expanding the amount of data collected, or it could include setting higher goals in areas such as improved visibility, fewer incident rates and reduced downtime. Safety professionals also can use the safety-system data to better measure and meet their corporate safety goals while constantly seeking opportunities to improve their future state.

Analyze and Optimize

Our comprehensive suite of analytics platforms is the foundation for your industrial digital transformation, a complete spectrum of descriptive to prescriptive analytics solutions for achieving business outcomes

such as Overall Equipment Effectiveness (OEE) improvement, safety performance, downtime reduction, and quality or process improvement.

- Comprehensive portfolio with enterprise-wide capabilities – Achieve enterprise-wide transformation with comprehensive, integrated solutions, tailored to your unique business goals and use cases.

- Source (Data) -to-plant-to-market visibility, insights, and sustainability – Gain real time visibility and contextualized insights for superior quality control, compliance, traceability, and strategic decisions using

solutions that connect your entire business ecosystem

- Scalable technology that’s adaptable and modular – Innovate, compete, and exceed market demands with a set of uniquely modular technologies that can adapt and scale to your specific business needs.

- Security and risk mitigation – Protect your company’s products, operations, finances, and customers using solutions developed with security and risk-mitigation at the design level, by the world’s principal OT experts.

Expand Digital Transformation Possibility With FactoryTalk Innovation Suite

FactoryTalk® InnovationSuite, powered by PTC, is a comprehensive portfolio that brings edge-to-enterprise analytics, machine learning, industrial internet of things (IIoT) and augmented reality (AR) to industrial operations. This powerful suite simplifies how your company manages data and makes it easier for everyone to access, understand, and leverage the information they need to make decisions.

InnovationSuite collects and consolidates information technology (IT) with operational technology (OT) from your existing equipment and systems, so you can make data-driven decisions that align with your exact needs. Your workforce can easily find the data they need to drive real improvements.

Safety Services

Finding Value Through a Safe Production Environment

How does your organization view industrial safety? Do you see it as an opportunity not only to meet compliance requirements, but also to reduce risk and maximize productivity? Safety no longer needs to be a burden on productivity or a mere cost of doing business.

With a strong safety culture, compliant safety procedures and contemporary safety technologies, best-in-class manufacturers have shown that they can help to protect people and directly benefit the bottom line.

DIGITAL THREAD

Connect business processes, systems, equipment and products with data

• Digital strategy & organizational change management

• Data science & artificial intelligence

• Manufacturing execution systems (MES)

• Product lifecycle management (PLM)

• Extended reality (AR/VR/MR)

• Supply chain management (SCM)

• Enterprise resource planning (ERP)

PRODUCTION AUTOMATION

Automate manufacturing and production operations

- Industrial automation control systems

- Distributed control systems (DCS)

- Power systems

- Drive systems

- Safety systems

- Custom/configured panel solutions

CYBERSECURITY & NETWORK INFRASTRUCTURE

Enable and secure industrial network connectivity

- Industrial cybersecurity

- Industrial network infrastructure & remote support

- Industrial data centers

ASSET OPTIMIZATION & WORKFORCE

Optimize performance of machines, equipment, systems and people

- Equipment repair & remanufacturing

- Asset & equipment inventory management

- Remote support & monitoring

- On-site & field services

- Safety solutions

- Training & learning

Comprehensive Safety Services

Our safety services address hazardous-energy control and machine safety. These offerings can help protect your safety investments and ongoing program integrity:

Hazardous energy control services provide you with lockout/tagout (LOTO) solutions in a variety of environments to help you manage employee safety without compromising productivity.

Machine Safety Services

Safety Functional Requirement Specification (SFRS), Verification, Validation – Our safety professionals can help certify that your machine safety system is properly designed, installed, and performing within defined parameters and standards. We can also support your installation and validation processes with the appropriate safety products, standards and training for your employees.

Integration and Start-Up support is designed to help you enhance machine productivity while maintaining workplace safety.

Compliance consulting can help you comply with industry and global standard design systems for functional safety. Such expertise can be crucial during risk assessments, standards identification, system engineering, evaluation and self-certification.

Risk Assessment – Safety risk assessments are not only a requirement of the safety standards maintained by regulatory agencies, but they also keep employees safe and production running. We offer safety assessment services to evaluate plant risks and help you make informed decisions that support the safety of your employees.

Training – our industry-leading experts can familiarize your workers with current and emerging industry standards, and provide them with examples for when to apply safety components. We collaborate with TÜV Rheinland to deliver functional safety expert training for technicians and engineers. These TÜV Rheinland certification training courses are the cornerstone of our Safety Training offering.

Safety Through Security

With more systems being integrated, the line between digital and physical infrastructure has become increasingly blurred. Addressing machinery security-related safety risks won’t just be a good practice, rather a necessity.

Machines must be designed and built so connections to other devices do not lead to hazardous situations. Connected hardware components, software and data critical to EHS compliance must be protected against accidental or intentional corruption.

Control systems must be designed and built to withstand intended and unintended external influences, including malicious third-party attempts to create hazardous situations.

It also will require mitigation from potentially dangerous consequences of physical and digital security attacks.

Fortunately, safety and security have some commonality in how you analyze and mitigate risks. In particular, both safety and security require you to perform a risk assessment, making that activity a good starting point to address safety and security together as part of a larger risk management strategy.

Of course, you can only address safety and security risks together if the OT and IT teams responsible for them are talking to each other and working together toward the same goal. This can be a significant hurdle to overcome. When OT and IT teams join forces to address safety and security together for the first time, outside support can help the teams coalesce and get off to a smooth start.

Critical Infrastructure requires industrial-strength security solutions. Are you at Risk?

- Low insight around vulnerabilities and risk

- Difficulties in OT patching

- Lack of visibility into network asset inventory

- No continuous threat detection

- Insufficiently segmented/air-gapped network

- Conflicts with IT/OT convergence roadmaps and uptime goals

Increase your security preparedness now with support from Rockwell Automation.

- The worldwide leader in industrial automation for 100+ years

- Industrial strength OT Security Operations Center for superior protection

- Unmatched precision in complex, multi-site deployments

- World-class partners including Microsoft, Cisco, Claroty, Crowdstrike and Dragos

Tiếng Việt

Tiếng Việt