Consulting, Solutions

CIP – Clean in place sensors

Together we get safe and competitive CIP automation done

Food safety

Investment

Efficient engineering

Efficient CIP operation

Reliable partner

One stop shop

The perfect solution for every application

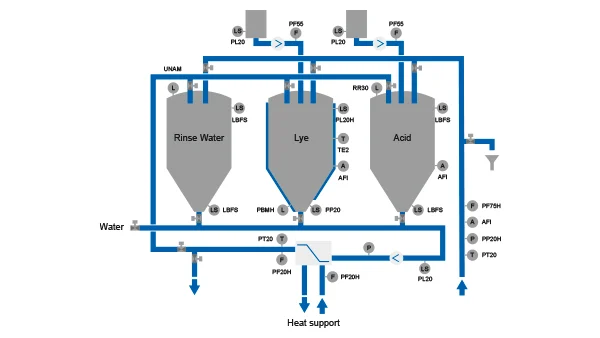

Concentrate dosing

Electromagnetic flow meter PF55S is the compact and robust solution for accurate dosing of detergents into caustic and acid tanks. Accurate control helps avoid overdosing, protecting both, plant and environment. Information on the used detergent is provided to the control system for traceability and documentation.

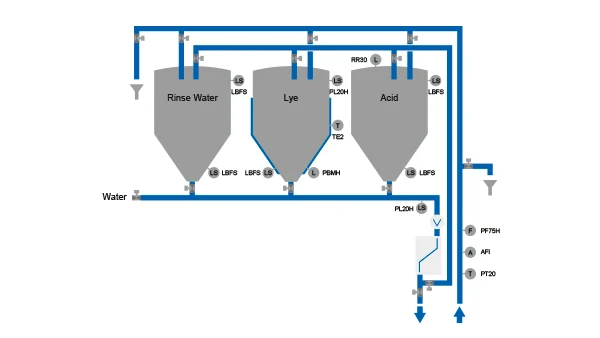

Quality measuring point and phase separation

Reliable conductivity measurement with fast temperature compen- sation is the basis for successful cleaning cycles, optimizing the use of cleaning agents and fast, accurate phase separation.

CombiLyz® AFI in rugged design with one-piece PEEK tip and integrated temperature sensor offers market-leading performance in terms of reaction time and signal quality. CIP is only safe if the requirements of concentration is also achieved in the back end of the cleaning cylce.

Tank temperature monitoring

Since temperature is one of the four main parameters, the correct temperature prevailing right at the start of the cleaning cycle saves valuable time. Temperature sensor CombiTemp® TFRH enables hygienic temperature measurement right inside the tank. The large DFON display changing color allows for clear readout even from a distance whether temperature is within the correct limits.

Point level detection

Universal level switch CleverLevel® is the perfect protection for process and environment. Safe limit detection, optionally ignoring or detecting any foam formation, prevents tanks from damage and any escape of cleaning agents into the drains. Finally, the empty- tank signal protects the cleaning process from failures caused by missing media.

Continuous level measurement

Flush mounted hydrostatic level measurement and displayed with CombiTemp PFMH sensor ensures the availability of cleaning agent for the next batch. The high accuracy of 0,1% max is unaffected by temperature changes, foam or uneven surfaces. The graphical touch display DFON changes color and make critical level visible from a distance

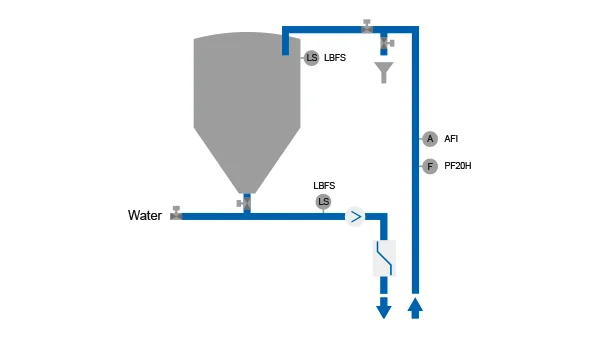

Pump protection

Level switch CleverLevel® installed directly in-line with the

CIP supply pump delivers reliable signals to avoid pump damage by dry run. Unaffected by build up, media characteristics and adherence, any lack of liquid that would disturb the cleaning will safely be detected.

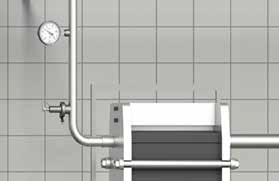

Heat supply monitoring

Flow sensor FlexFlow PF20 delivers required information both on flow speed and hot water supply temperature from a single sensor. Tight monitoring of energy and process uses only one process connection. The MEX5 gauge indicates the pressure currently present in the system.

Condition control in CIP supply

The sensitive pressure sensors PP20H detects changes in the CIP loop. Leakages causing pressure drops are recognized as well as increasing pressure pointing to blockages.

Velocity in CIP supply

Used in the CIP supply line, the FlexFlow serves two purposes. It ensures that the supply pump already delivers the desired velocity. Besides that, the flow and temperature data can be used to preset the heat exchanger operation. Both help to safe time until the de- sired quality parameter are reached and cleaning time counts.

Quality point temperature

Since the temperature plays a major role, the CombiTemp TFRH sensor in the quality measurement point is equipped with a large DFON display. As in CombiLyz® and CombiFlow®, the display will change colors, when the value is out of range.

Velocity control in the return pipes

Electromagnetic flow meter PF75H with 0.2% accuracy delivers best-in-class performance and reporting stability of cleaning condi- tions, further it remains unaffected by any temperature change. In a robust and compact all-stainless steel design with large DFON touchscreen display, CombiFlow® is the robust, stainless steel product solution.

Scalable CIP solutions for perfect resource utilization

WEBINAR: Smart Sensor Solutions for CIP Processes

Join us for an exclusive webinar hosted by Servo Dynamics in partnership with Baumer, designed to introduce advanced sensor solutions tailored for CIP (Clean-In-Place) processes in the Food & Beverage industry.

Tiếng Việt

Tiếng Việt