Consulting, News, Solutions

Baumer| Sensors for milk processing

Do not stand still – you can take the next step with us

Since its establishment in 1952, Baumer has been an experienced partner for customer-oriented solutions in process automation. The close collaboration with users and customers results in prod- ucts that fulfill 100% of the requirements of the process and its control. To provide the food and beverage industry with excellent solutions, we cooperate closely with leading international food manufacturers. In the process, the engineering effort and daily life are combined into a successful application.

1. Exceptional performance

Quick response times coupled with the high accuracy of our sensors allow you to optimize your processes while saving energy, time, and resources without compromising food safety.

2. Turn innovations into success

Together we develop solutions that set new standards. Our dual channel sensors increase your flexibility because they communicate with both a digital IO-Link interface as well as analog 4…20 mA signals. They are the bridge to the digital future but can also be optimally used in contemporary systems

3. Compliance with legislation, standards, and specifications

Baumer sensors are certified according to international standards. Developed for the food and beverage industry, they excel in this sector with its great chal- lenges for electronic components. They comply with all requirements for hygienic design, material and surface quality. Designed and built according to the highest requirements for robustness, they resist water, conden- sation, heat, cold, vibrations, and aggressive media, while allowing 24/7 operation. Exceeding the standard, the proTect+ impermeability concept guarantees that sensors are impermeable across the entire life cycle. The sensors even withstand intensive external cleaning.

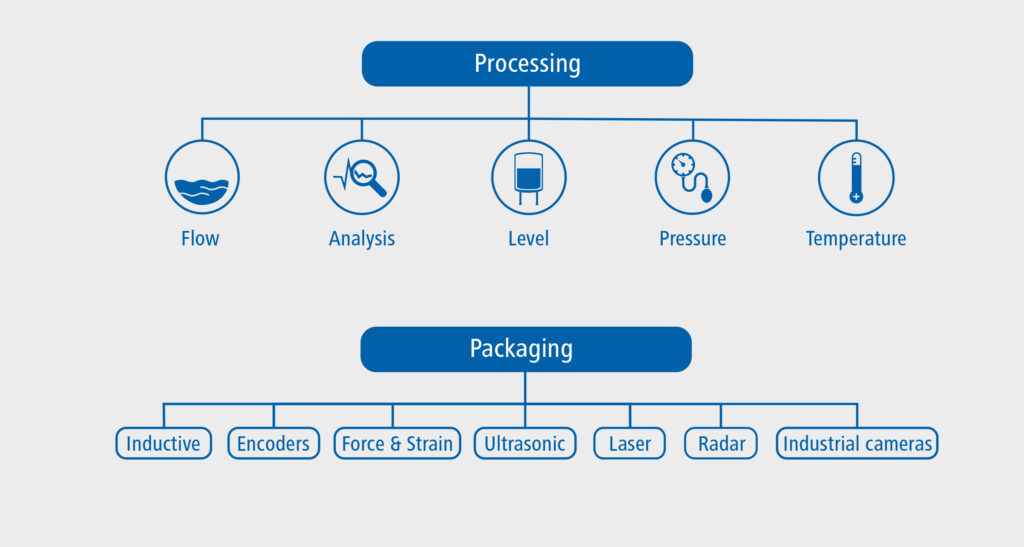

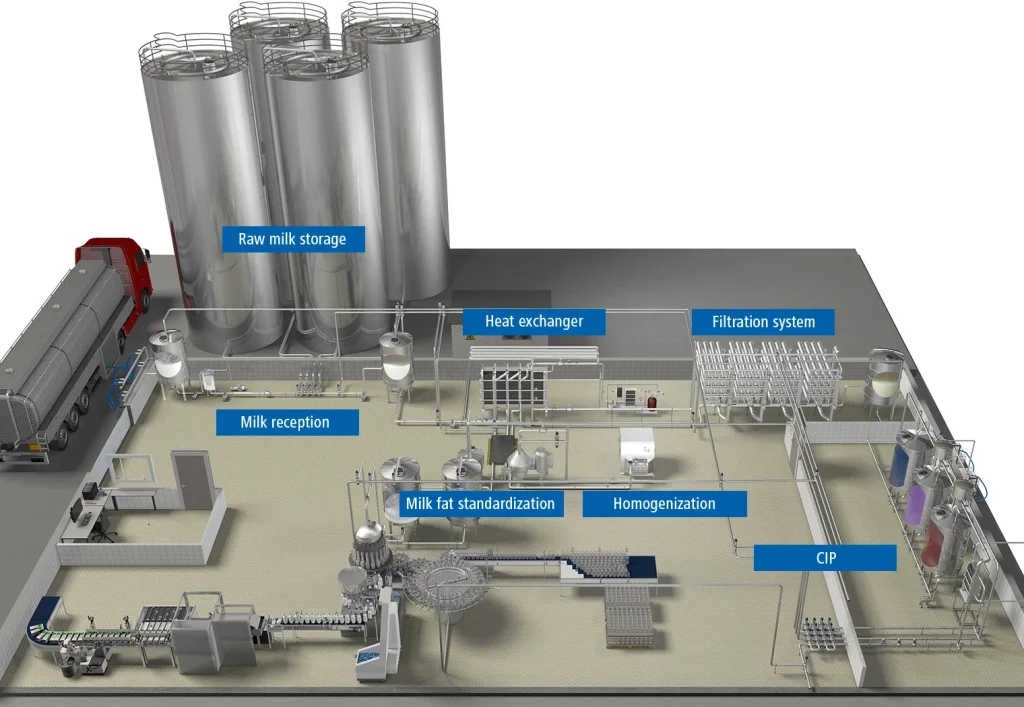

From raw material supply to the delivery ramp

Baumer supports you in every step of the supply chain. From truck scales to the inventory management of tanks and silos up to processes such as heat exchangers or CIP, you can optimize your production with our sensors. Rotary encoders, position and distance sensors, optical systems, as well as force and strain sensors complement the portfolio in the packing area along with the world’s most economic solution for gluing cartons.

Dairy production, much more than just milk!

For more than three decades, Baumer has been the partner of leading international dairy groups as well as local artisan dairies. In the development and design of our sensors, we already consider the conditions they are going to face. These include vibration in pipes as well as condensation formation due to cold production and heat during sterilization. Our focus is always on a hygienic design for effective and reliable cleaning, for the production of yoghurt, cheese, butter, and ice cream.

1. Receipt of milk

The effectiveness of subsequent processes can only be evaluated correctly if the initial measurement was correct. Following transport, degassing has the important task of ensuring that subsequent sensors can operate correctly. Optimally operating systems ensure accurate measurement results, quick cooling, and safe further processing of the milk.

Overflow protection against milk and milk foam

CleverLevel®

One of the main tasks inside vacuum-supported degassing containers is protecting the vacuum system from milk or milk foam. To optimally operate the system, the CleverLevel® can be precisely adjusted to the process. This way, it can react to either foam or milk. In the version with sliding connection, the height can additionally be matched to the tank. The extremely robust stainless steel housing features all-round LEDs that indicate the switching state.

Quick level measurement

LSP

In small containers with little content and high throughput, keeping the filling level constant is a challenging task. Thanks to its quick response time, the LSP level sensor is the appropriate solution for such applica- tions. Adhesions such as grease, protein, or lactose on the sensor do not affect the measurement performance.

Treatment of raw milk

CombiPress® PFMH, CleverLevel® PL20H

During its collection and transport, milk can absorb up to 30% air. This prohibits the use of many sensors. Run-time processes hardly have the signal strength to measure the filling level as precisely as the Combi- Press® PFMH hydrostatic level sensor. When it comes to overflow and empty messages in particular, the advantages of the flexible frequency sweep technology of the CleverLevel® PL20H come into play. The level switch reliably detects either the liquid phase or the foam. This also applies if cream, protein, or lactose collects on the sensor.

Temperature measurement in the storage tank

TER8

Temperature measurement in a tank with a stirring unit is difficult because the milk should receive as little resistance as possible. At the same time, it is advantageous if a sensor that is flush in the front can be reliably cleaned with the standard CIP process. The PEEK surface of the TER8 temperature sensor reduces the effect of the ambient temperature and offers mechanical and cleaning advantages compared to protective pipe installations.

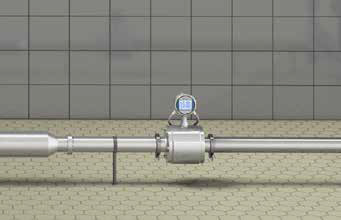

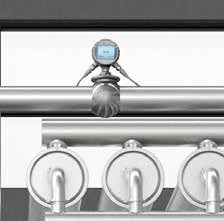

Receipt of milk and quantity measurement

CombiFlow® PF75H

Following the degassing, the milk is well prepared for its volume to be measured by a CombiFlow® PF75H magnetic inductive flow sensor. This offers superior accuracy of up to 0.2%, a robust design, and temperature stability. The compact, fully stainless steel sensor provides reliable base data for the subsequent processes. The graphical DFON display with touch function ensures that the information is clearly visible even from a distance.

2. Milk storage tanks

Precision and hygienically clean operations are the key to the successful implementation of the subsequent milk processing steps.

Hydrostatic level measurement

CombiPress® PFMH Long Shell

Planning of the milk quantity to be available for subsequent processes requires precise measurement of the existing quantity. Inside the tank, this is optimally carried out by the CombiPress® PFMH hydrostatic level sensor. The long housing was developed for insulated tanks. The sensor is perfectly suited for the cold environment with condensation precipi- tation. It provides precise measurement values even during hot cleaning processes. In the CombiPress® PBMH variant, the sensor is also available without a DFON display.

Empty tank notification

CleverLevel® PL20H

The application options for a level switch go far beyond the reliable empty notification. The CleverLevel® PL20H protects the tank dome from milk and milk foam, and the pump from dry runs. With its flexible foam detection or blanking, it allows the complete draining of the tank. Thanks to its compact design and small process-contact surface, it can be integrated into the process in a very flexible and hygienic manner. Deposits do not affect its performance. Drops that wash over the sensor during the CIP process, for example, do not result in switching.

3. Thermal treatment

Heat exchange systems combine all requirements for precise measurement. The process should be reliable, ef- fective against microorganisms, yet gentle without affecting product quality and as energy-efficient as possible. Critical control points meet operational excellence.

Monitoring the pasteurization temperature

PT20H

A quick temperature sensor has the greatest effect on the reliability and performance of a heat exchanger. A very quick t90 time as pro- vided by the PT20H allows the safety reserves of the heating to be reduced without risking falling below the PE. This prevents negative effects on the taste and energy consumption due to unnecessarily high temperatures.

Energy monitoring and process safety

FlexFlow® PF20H

Measuring the quantity and temperature of the heating water in the input to the system with the FlexFlow® PF20H makes it possible to determine the use of resources batch by batch. An increased energy requirement is a sign that either the product side must be cleaned or the media side must be descaled in the system.

Pressure gradient

PP20H

After the successful thermal treatment, it must be ensured that the treated milk is not exposed to untreated milk or even the cooling medium. The PP20H pressure sensors measure reliably whether the required pressure gradient is pres- ent. The evaluation of the pressure situation in the system allows optimization of the cleaning cycles. The sensor performance is neither affect- ed by high nor changing temperatures nor by condensation formation in cold areas

4. Filtration

Filtration and membrane filtration systems are used for removing coarse particles or as an alternative to ther- mal treatment. Ensuring the required pressures and flow rates requires the consumption of energy, which can be optimally used with the help of the right sensors.

Filter loading

CombiFlow® PF75H

An accurate measurement of the pump and module performance requires a precise sensor, such as the CombiFlow® PF75H magnetic inductive flow sensor. Monitoring the flow quantity allows conclusions about the load that the modules must bear as well as their current performance capacity. Breakdowns and the need for cleaning can all be detected. The sensor provides an excellent flow signal for both cold production and hot cleaning.

Phase separation

CombiLyz® AFI

The optimum phase separation of water and milk as well as the cleaning media significantly influences the effectiveness of the operation. This applies even more so to filtration systems due to their large surface area. The CombiLyz® AFI conductivity sensor offers the fastest response time even in the case of temperature changes. This reduces losses and increases the system availability.

Monitoring the filter performance

CombiPress® PFMH

Highest precision makes the CombiPress® PFMH pressure sensor predestined to mon- itoring pressure changes in filters. The early response to changes increases the holding time and thus the entire flow quantity. The uniform supply of milk to all membrane sections im- proves the performance of the overall system.

5. Milk standardization

Separators are used for the removal of undesired particles as well as skimming in standardization. Stable input and output processes contribute to optimum operation.

Cream dosage in standardization

CombiFlow® PF75H

The precise dosage of cream is worth every penny. The CombiFlow® PF75H magnetic inductive flow sensor measures with high accuracy in both the cream and the skimmed milk. Its compact, fully stainless steel design facilitates its installation in narrow systems. With the DFON display, the current situation can be monitored any time from a distance as well.

Pressure monitoring of the separator

PP20H

Stable pressure in the input and output to the separator is a basic requirement for the optimum operation of the separator and the return dosage. With its robust stainless steel housing and electronics that are fully secured by socketing, the PP20H pressure sensor provides long- term stable measurement performance. The sensor is not affected by condensation.

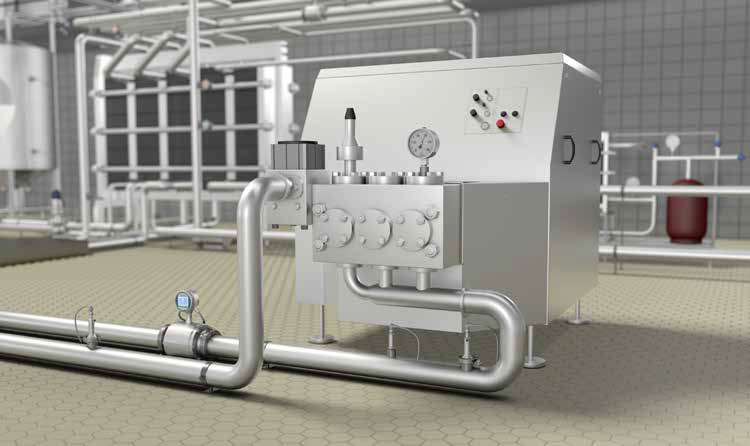

6. Homogenization

The high energy consumption of a homogenizer pays off in the form of a more intense milk color and a better feeling in the mouth especially when the process conditions in the surroundings, flow rate, temperature, and pressure conditions are stable.

Energy monitoring

FlexFlow® PF20H

In addition to the electricity needed to operate the huge motor, cooling water can have a significant effect on the operating costs. With the FlexFlow® PF20 calorimetric flow sensor, measurement of the quantity and output tem- perature opens up possibilities for determining consumption and evaluating changes for pre- ventive maintenance. The compact and robust sensor can be easily integrated into the pipe.

Measurement of the input temperature

PT20H

Very precise and very fast temperature mea- surement allows the homogenizer to provide the medium at an optimum temperature. The compact PT20H temperature sensor with its short t90 time allows an early reaction to pre- vent the milk from arriving at the homogenizer too cold.

Homogenization pressure

MEX5

As the pressure on the homogenization valve makes a difference to both quality and energy consumption, the dampened manometer MEX5 shows this pressure reliably at all times. Unaffected by vibrations or high pressure fluctuations, it is a robust everyday tool from Baumer Bourdon.

7. CIP system

Cleaning is one of the most important processes. This is not only due to its effect on product safety and quality but also due to the associated costs that need to be optimized: for water, energy, cleaning agents, and above all the loss of production time. Of course, this starts with hygienically designed systems.

Quality measurement point concentration and phase separation – CombiLyz® AFI

The fast, temperature-compensated conduc- tivity measurement is the prerequisite for the optimal use of cleaning agents and very precise phase changes. In this way, the CombiLyz® AFI conductivity sensor supports the CIP process. The robust sensor body, fully made of PEEK with integrated temperature compensation, provides the measurement values faster than

Quality measurement point flow velocity

CombiFlow® PF75H

With its precision of 0.2%, the CombiFlow® PF75H electromagnetic flow sensor provides precisely the information that is required to ensure cleaning success with the desired flow velocity in the return flow. Temperature changes do not affect the measurement performance. Not only the sensor but also the housing with the DFON touch screen display are fully made of stainless steel and very robust and compact.

Quality measurement point temperature

CombiTemp®

As the temperature plays a key role in reliable cleaning, the CombiTemp® TFRH tempera- ture sensor with its high precision and DFON display ensures compliance with threshold values and their clearly legible display. Similar

to the CombiLyz® and CombiFlow®, the display changes its color if the measured value is outside of the set threshold values.

Tiếng Việt

Tiếng Việt