Solutions

Introducing Logix SIS: Solution for Process Safety

The Challenges

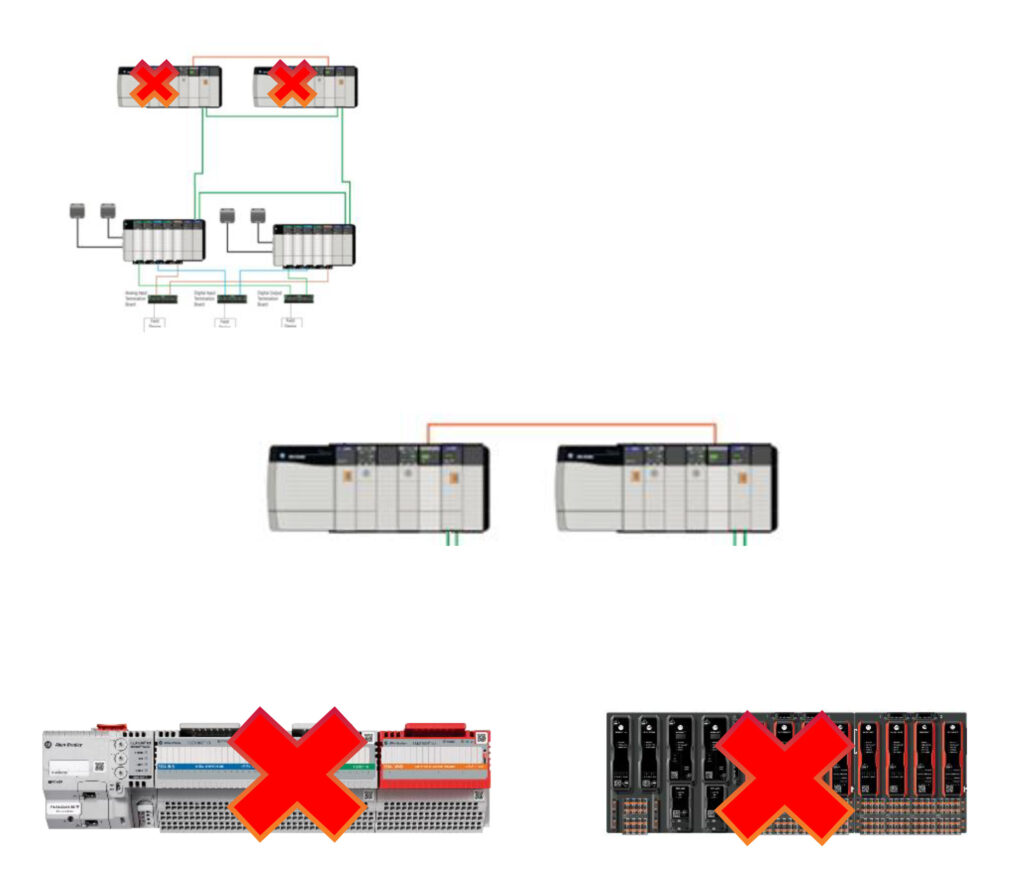

“There are no highly available solutions to achieve safety in the latest hardware (5580)”

“I have to budget for implementation cost/time with the ControlLogix® SIL 2 w/ 1715 solution”

“I am unable to use additional features available with the newer I/O systems in ControlLogix® redundancy safety systems”

The Solution

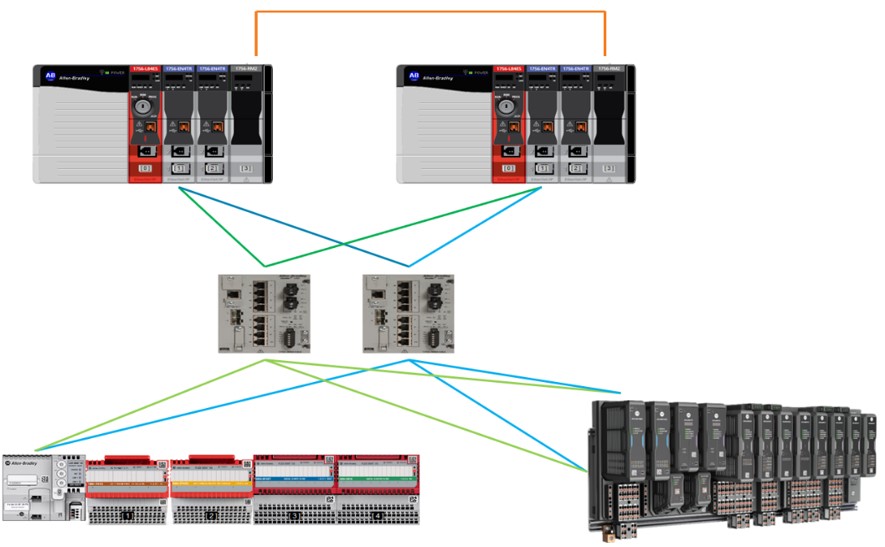

- Adds safety into 5580 redundancy

- Achieve SIL 2 or SIL 3

- Leverages the latest controller and I/O solutions

- Expands upon existing safety implementation

- Supports the following:

- Concurrent safety execution

- Concurrent communications for standard and safety I/O

- Granular safety signatures

Configuration details

- Functionality unlocked with only a firmware update

- Available with V37.011 firmware

- Safety configurations are now handled completely by the controller

- Custom AOIs are no longer needed

- Concurrent safety execution in the primary and secondary controller

- Enables embedded safety diagnostics that are transparent to the end user

Features

- Enhanced containerization for safety edits

- Leverage granular safety signatures

- Utilized the latest 1756 hardware (5580) to build this solution

- There are no new specific catalog numbers required

- Take advantage of the latest I/O platforms (5094, 5015)

- Additional instructions supported

- Leverage instructions added to Ladder Logic Safety Editor

Avoid downtime during updates

- Upgrade to future versions for new features while running

- Leverage Redundancy System Update (RSU) to update all parts of the system:

- The controller

- The communication modules

- The redundancy modules

- NO downtime is needed to perform the RSU

- The secondary chassis will be unavailable during the update

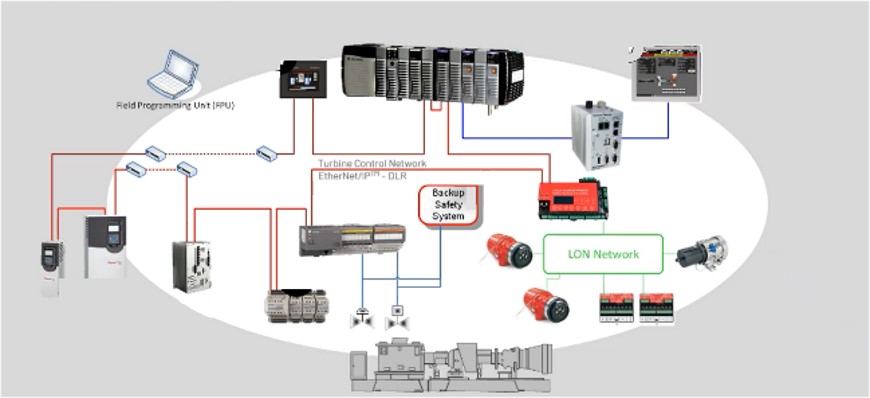

Logix SIS Industries

Heavy Industries

Oil & Gas

Power Generation

Tunnels/Transport

Baggage/Package Handling

Entertainment

Process Safety & Hybrid Safety

Targeted Applications

1.General Process Safety

Simplex IO is required for non-critical functions such as horns, lamps, and safety gates around machinery

Oil and Gas

2.Hybrid Safety

I/O availability is not the priority

Redundancy controllers provide the best flexibility

A mix of safety and standard control loops in the same controller

Reliability is very important; shutdowns are not OK

3.Tunnels/Transportation/Baggage Handling

Simplex I/O is required for non-critical systems

Redundant I/O will reside on critical systems such as fans

Simplex Safety I/O will be wired with relays in the event of I/O failure

4.Entertainment

Controller redundancy for availability

Simplex Safety I/O for fail-safe applications

5.Multi-zone control of robot lines that utilize machine safety

Each zone can be shut down independently

The controllers failing would shut down the entire line i.e. more important than I/O

6.Green Hydrogen

Emerging market with large growth potential

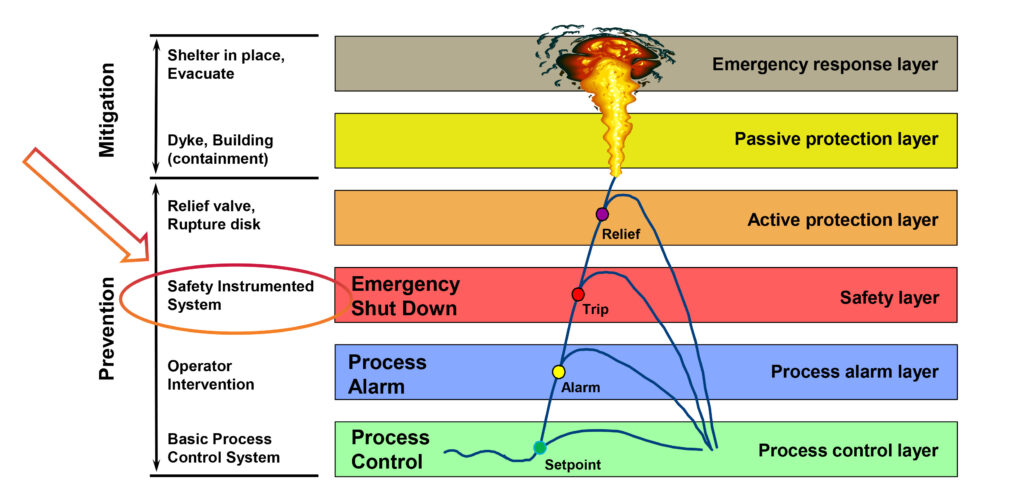

Layers of Protection

Where does an SIS fit in Process Safety?

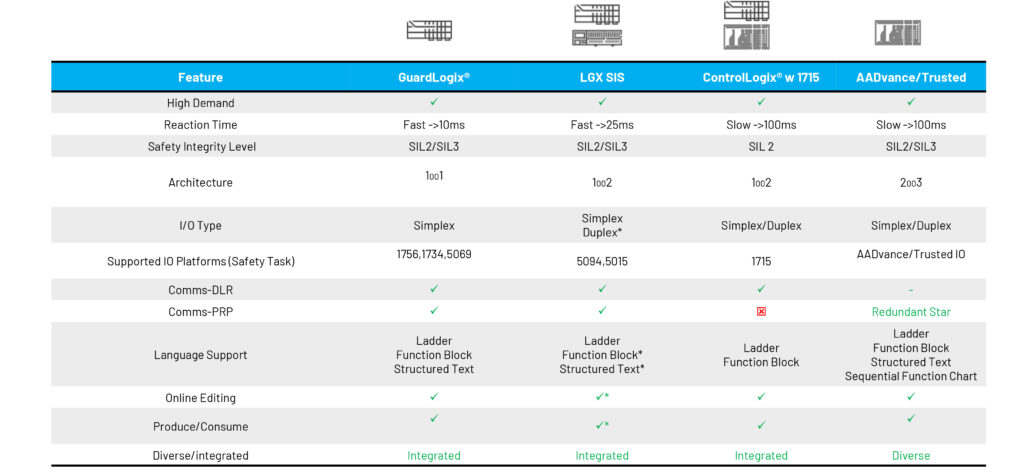

Safety Solution Comparison Overview

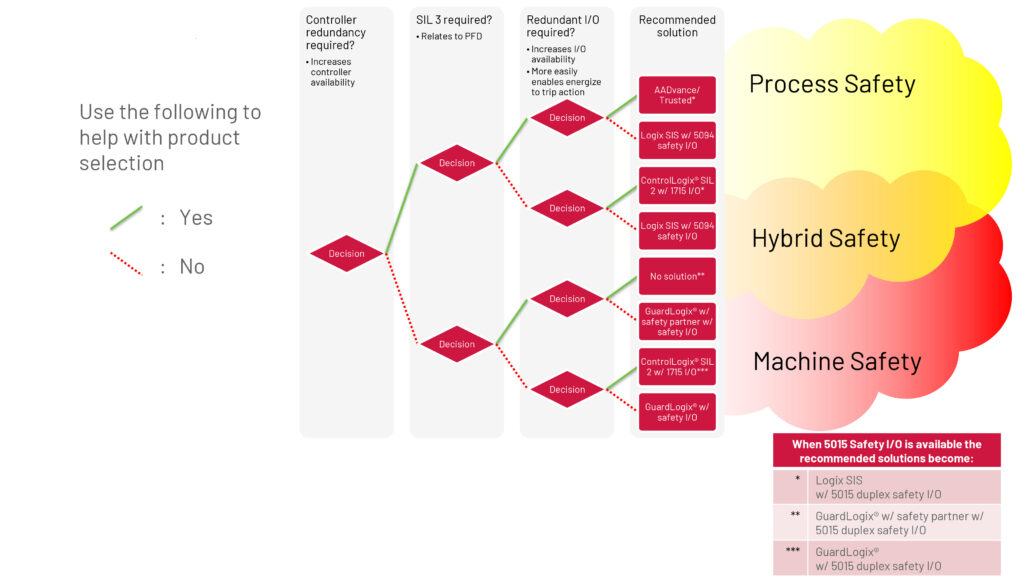

System Selection

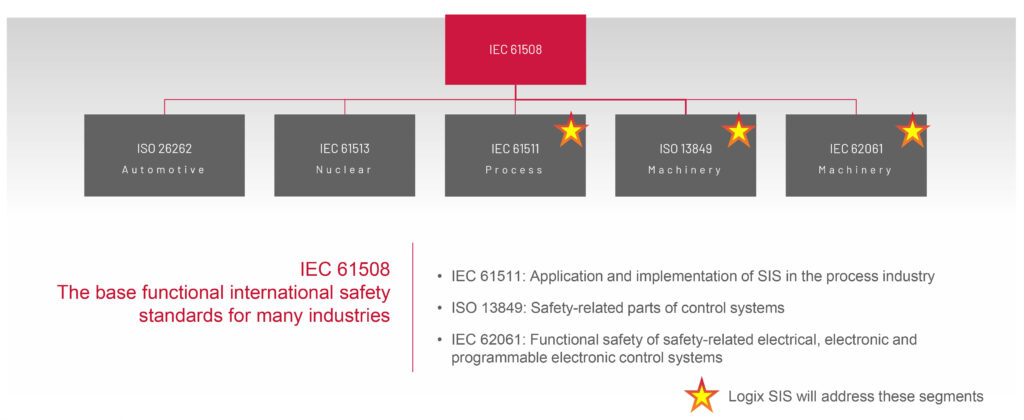

Safety Certifications

Visualization of how the safety certifications are related

Tiếng Việt

Tiếng Việt