Solutions

UR10 Robots Revolutionize the Painting Process

In Short

Brandt A/S, a well-established Danish company with over 60 years of experience in the painting industry, has taken a significant step towards innovation by implementing UR10 cobot solutions in its production process to achieve consistent quality and increase efficiency. With technology from UR+ partner Nordbo Robotics’ Mimic software, the robot can replicate the operator’s movements one step at a time, then execute them with unprecedented precision. The implementation of the cobots has transformed the way the company handles painting tasks, leading to significant improvements in productivity and quality.

Brandt A/S

Industry: Furniture and other equipment

Country: Denmark

Number of Employees: 100+

Cobot used: UR10

Components used: Mimic Kit from Nordbo Robotics

We started with two robots, but we also have other platforms where we need to implement them because we believe robots and digitization – that’s the future

Rene Damgaard Hansen, CEO of Brandt A/S

The business transformation:

How They Did It

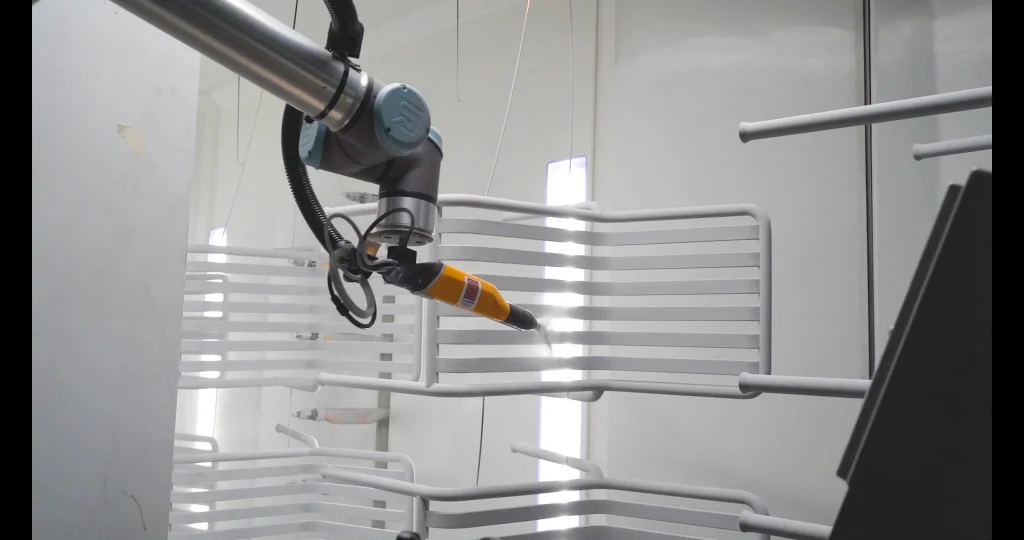

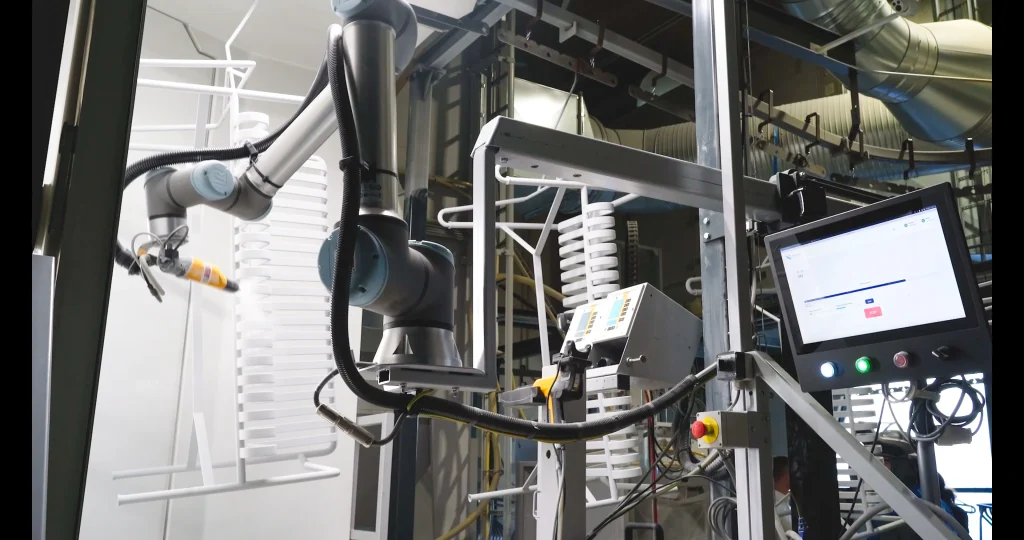

Before the introduction of the cobots, employees performed manual spray painting 24/7. Now, Brandt A/S uses the Mimic technology from Nordbo Robotics that via a pose tracker sensor records the painters’ movements and transfers them to the cobot, which performs touch-up tasks with unprecedented precision. The cobot works closely with operators and is designed to mimic their every move.Universal Robots’ cobot is integrated with Nordbo Robotics programming unit and G.A. Hansen’s Gema powder box. This enables seamless communication between the robot and peripheral equipment, resulting in consistent quality from run to run. Operators can easily create programs on the line track, and the cobot automatically detects the start of each item, ensuring continuous and efficient production.With the UR+ ecosystem, Brandt A/S has access to a wide range of components, software packages, and applications tested to seamlessly integrate with UR cobots, including Nordbo Robotics’ Mimic software. This has enabled operators to program the cobot intuitively without needing in-depth technical knowledge. “We have taken the spray gun that the operators normally use and made it possible for them to program the robot just as they would usually use the spray guns,” says CCO at Nordbo Robotics, Sabina Kethelz, emphasizing the user-friendly approach and minimal need for operator interaction, highlighting Universal Robots’ focus on delivering a comprehensive and accessible automation solution. The system is also approved for Zone 22 with extended ATEX approval, which is an EU directive that the system complies with.

In fact, you don’t need to have a particularly large batch before it makes sense to implement a painting robot. And it doesn’t require extensive training to use the robot

Sune McDonald Bertelsen, Country Manager, Universal Robots.

UR+ products used:

Automation challenges solved:

Freeing up manual labor from repetitive spray paint tasks

Quick adaptation to highly varied product lines

Key value drivers:

Higher produtivity due to greater throughput

Fast programming of simple and complex processes

Consistent paint coverage on all products

Tasks solved by collaborative robots:

Automated powder coating process with UR10e and Nordbo Mimic software

Tiếng Việt

Tiếng Việt