Tin tức, Tự động hóa Công nghiệp, Tư vấn

Selecting the Right Electric Motor for Your Application

Choosing the correct electric motor is a key factor determining the efficiency, reliability, and operating cost of the entire system. A wrong choice can lead to energy waste, reduced equipment lifespan, or even serious failures. This detailed guide will help you grasp the technical criteria and step-by-step process to select the most suitable electric motor for all applications, from heavy industry to precise medical equipment.

What is an Electric Motor?

Concept of an Electric Motor

An electric motor is an electrical device used to convert electrical energy into mechanical energy (rotational or linear motion). The basic operating principle relies on the interaction between a magnetic field and an electric current to produce mechanical force, also known as torque.

Common Electric Motor Classifications

The market offers many types of electric motors, classified based on the power source, construction, and operating principle:

- AC Electric Motors (Alternating Current):

- Durable, easy to manufacture, low maintenance costs.

- Often used in applications requiring stable speed such as pumps, fans, and compressors.

- Classification: Single-phase motors (220V) and Three-phase motors (380V).

- DC Electric Motors (Direct Current):

- Have very high starting torque, suitable for applications requiring immediate startup or easy speed control.

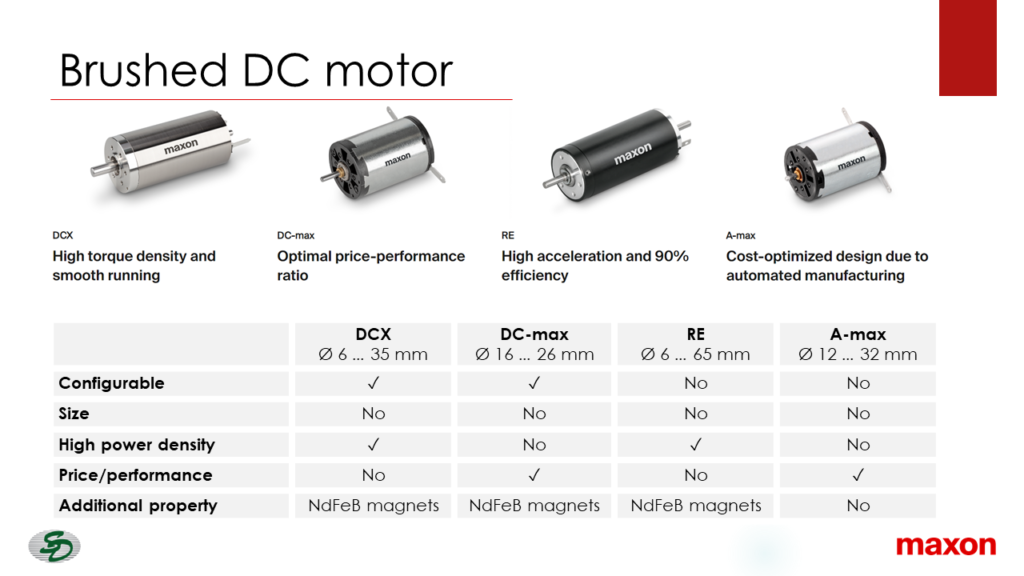

- Brushed DC Motors (BDC): Simple structure, high torque, but require periodic brush maintenance.

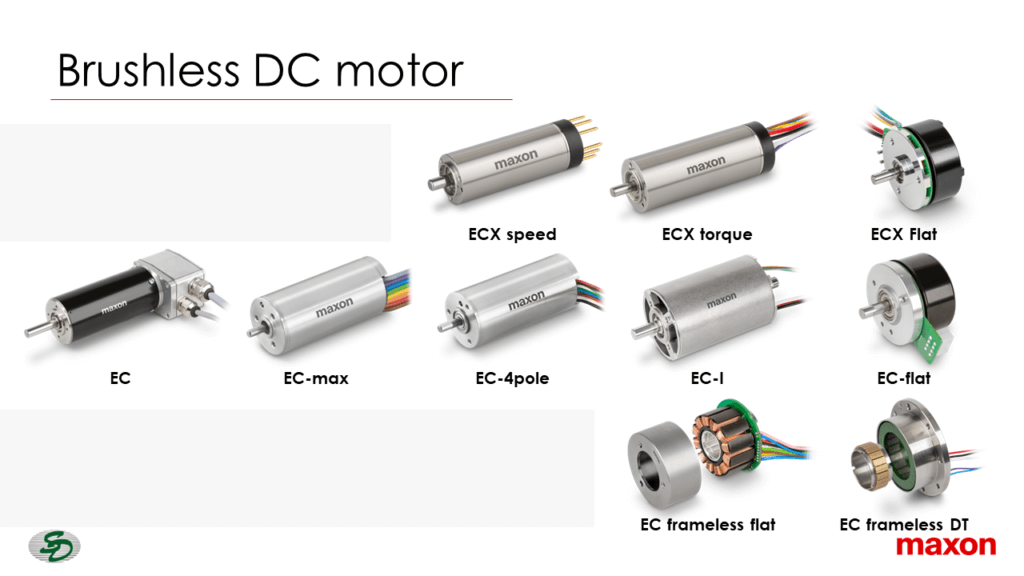

- BLDC Motors (Brushless DC):

- Operate similarly to DC motors but without brushes, which minimizes maintenance and extends motor life.

- Operate extremely quietly and are highly efficient, ideal for medical devices, healthcare, and robotics.

- Synchronous / Asynchronous Motors (Induction):

- Asynchronous (Induction): The rotor speed is always less than the speed of the rotating magnetic field (supply frequency). This is the most common type of 3-phase motor in industry.

- Synchronous: The rotor speed equals the speed of the rotating magnetic field. Used in applications requiring precise speed or when a high-power, high-efficiency motor is needed.

- Servo Motors, Permanent Magnet (PMDC/PMSM):

- Permanent Magnet Synchronous Motor (PMSM): Uses permanent magnets in the rotor. High power density, compact size relative to power output, large torque, often used in high-precision applications (servo, electric vehicles).

Applications of Electric Motors in Industry and Daily Life

Electric motors are the heart of every industry:

- Heavy Industry: Large capacity pumps, fans, conveyors, air compressors, cranes, crushers.

- Manufacturing and Production: CNC machines, industrial robots, packaging machines, automation systems.

- Medical Equipment: Ventilator pumps, patient lift devices, analysis machines (often use BLDC, Maxon motors).

- Transportation: Electric cars, trains, ships (use high-power motors or BLDC/PMSM for personal electric vehicles).

Key Criteria for Selecting an Electric Motor

Determining Load Requirements and Torque

This is the first and most crucial step. You need to identify the type of load and the required torque to operate it.

| Load Type | Characteristics | Typical Applications |

|---|---|---|

| Light Load | Low, stable torque, easy starting required. | Ventilation fans, light mixers. |

| Medium Load | Medium torque, may require slightly heavier starting. | Centrifugal pumps, small conveyors, machine tools. |

| Heavy Load | Requires large starting torque, continuous operation with high loads. | Air compressors, crushers, heavy material mixers. |

Torque Calculation Formula (T): The required torque T (Nm) is calculated based on power P (kW) and speed n (revolutions per minute – rpm):

T = (9.55 x P (kW)) / n

Selecting the Appropriate Motor Power

The motor power (PkW) must be sufficient to supply the required torque to the load, plus efficiency losses.

How to Calculate Motor Power: The motor’s output power (mechanical power) must be greater than the required load power (P_load).

P_rated = P_load / (Efficiency x Ks)

Where:

- P_rated: Motor’s rated power (kW).

- P_load: Required load power (kW) (e.g., hydraulic power of a pump, traction power of a conveyor).

- Efficiency: Transmission efficiency (if gearbox, belts are involved…) and motor efficiency.

- Ks: Safety factor (typically chosen from 1.1 to 1.3).

Common Power Ranges: Industrial AC motors typically range from 0.18 kW to 250 kW.

- 0.18 kW – 2.2 kW: Small pump, small fan applications.

- 3.7 kW – 22 kW: Common industrial applications (water supply pumps, medium conveyors).

- 30 kW – 90 kW and up: Large air compressors, cranes, crushers.

Avoid Under- or Oversizing Power:

- Undersizing: Causes overload, high temperature rise, reduced winding lifespan, and potential motor burnout.

- Oversizing: Wastes initial investment costs, and more importantly, reduces energy efficiency because motors operating below load often have much lower efficiency than when operating near 75% – 100% of their rated load.

Voltage and Power Source Type

- Single-phase 220V Motor: Typically used for small power applications under 3 kW in residential or small workshop settings.

- Three-phase 380V/400V Motor: Most common in industry. Higher efficiency, more stable torque, and easily controlled by a Variable Frequency Drive (VFD).

- Low Voltage (12V / 24V / 48V): Primarily used for DC, BLDC, PMSM motors in electric vehicles, robots, handheld devices, and mini-machines.

Rotation Speed & Speed Control Requirements

- Revolutions Per Minute (rpm): Standard 50Hz asynchronous AC motors typically have the following standard speeds (depending on the number of poles):

- 2 poles: ~ 2900 rpm

- 4 poles: ~ 1450 rpm

- 6 poles: ~ 960 rpm

- 8 poles: ~ 750 rpm

- Is a Variable Frequency Drive (VFD) necessary?

- If your application requires variable speed, soft starting, or energy savings, using a VFD is mandatory.

- Inverter Duty motors are often specially designed to withstand voltage fluctuations and high frequencies.

Motor Working Environment

The environment determines the Ingress Protection (IP) rating and the motor’s construction material:

- High Temperature: Requires a higher Insulation Class (F, H) and an efficient cooling system.

- Humidity/Water: Requires a high IP rating (e.g., IP55 for dust and water jet resistance, IP65/IP66 for pressurized water resistance).

- Dust – Chemicals: Requires a Totally Enclosed Fan Cooled (TEFC) motor and anti-corrosion materials (aluminum body, special epoxy paint).

- Explosion Proof (Ex): It is mandatory to select certified explosion-proof motors for environments with flammable gases or dust (petroleum, chemicals).

Electric Motor Efficiency & Energy Consumption

Motor Efficiency (Efficiency) is the ratio between the mechanical power output and the electrical power consumed.

- Energy Label: Countries mandate minimum efficiency classes.

- IE Efficiency Classification (IEC 60034-30-1):

- IE1: Standard Efficiency.

- IE2: High Efficiency.

- IE3: Premium Efficiency (currently the minimum standard in many developed markets).

- IE4: Super Premium Efficiency (maximum energy savings).

- Choosing an IE3 or IE4 motor helps save significant electricity costs over the motor’s lifespan.

Design – Size – Installation Requirements

- Frame size: Standard designation (e.g., 100L, 132S). The frame size defines the shaft center height, shaft diameter, and bolt hole positions.

- Mounting Type:

- B3: Foot mounted (most common).

- B5: Large flange (often used for pumps).

- B35: Both foot and flange mounted.

- Shaft Type: Hollow shaft, solid shaft, keyed shaft, tapered shaft (depending on the transmission device (coupling, gear, pulley) you use).

Guide to Selecting Electric Motors for Specific Applications

Selecting Electric Motors for Water Pumps – Fire Pumps

- Criterion: Power must match the required Flow Rate (Q) and Head (H) of the pump.

- Note: Fire pumps require extremely high reliability and usually direct starting. Water supply/wastewater pumps should use a VFD to adjust flow rate, save energy, and reduce starting pressure.

- Motor Type: 3-phase AC motor IE3/IE4, minimum IP55 protection, B5 mounting type.

Selecting Electric Motors for Fans – Ventilation – HVAC

- Load Characteristics: Light load, high speed (typically 1450 rpm or 2900 rpm).

- Recommendation: Should choose High-Efficiency (IE3/IE4) motors because fans often operate continuously for long periods.

- Control: Large industrial fans should use a VFD to optimize flow rate and save energy (because power is proportional to the cube of speed: P is proportional to n^3).

Selecting Electric Motors for Conveyors – Mechanical Drives

- Load Characteristics: Heavy load, requires large starting torque.

- Mandatory: Most conveyor systems require a Gear Motor to reduce speed and increase shaft torque.

- Motor Type: 3-phase AC motor combined with a gearbox.

Selecting Electric Motors for Air Compressors

- Power: Typically from 2.2 kW to 250 kW.

- Requirement: Needs a motor with large starting torque to overcome the initial compression pressure. Needs a durable motor capable of continuous heavy load.

- Note: Modern screw compressors often use a VFD to adjust air flow and save electricity.

Selecting Electric Motors for Electric Vehicles / Electric Motorcycles / Electric Bicycles

- Classification: Small to medium power motors (250W – 5000W).

- Motor Type: Primarily BLDC (Brushless DC) or PMSM (Permanent Magnet Synchronous Motor) because they are highly efficient, compact, and easily controlled for speed/torque via an electronic controller.

- Voltage: Typically low DC voltage (12V, 24V, 48V, 72V).

Selecting Electric Motors for Agitators, Mixers, Crushers

- Load Characteristics: Very heavy load, requires extremely high shaft torque and low rotation speed.

- Solution: Mandatory use of a Gear Motor with a large gear ratio.

- Motor Type: High-power AC motor, combined with a worm or planetary gearbox.

How to Calculate Electric Motor Power Accurately (with examples)

Formula for Calculating Electric Motor Power

| Application | Formula for Calculating Load Power (P_load) |

|---|---|

| Centrifugal Pump | P_load (kW) = (Q (m3/s) x H (m) x Density (kg/m3) x Gravity Acceleration (m/s2)) / 1000 Or simply: P_load (kW) = (Q (m3/h) x H (m)) / (367 x Pump Efficiency) |

| Conveyor System | P_load (kW) = (F_traction (N) x v (m/s)) / 1000 |

| Lifting (Winch System) | P_load (kW) = (m (kg) x Gravity Acceleration (m/s2) x v (m/s)) / 1000 |

After obtaining P_load, the required rated motor power to be selected:

P_rated = P_load / (Efficiency x Ks)

(Efficiency: transmission system efficiency; Ks: Safety factor 1.1 – 1.3)

Practical Calculation Example

Example 1: Calculating Power for a Conveyor

- Required traction force (F_traction): 5000 N

- Conveyor speed (v): 0.5 m/s

- Transmission efficiency (Efficiency): 0.85 (85%)

- Safety factor (Ks): 1.2

- Calculate Load Power (P_load):

P_load = (5000 x 0.5) / 1000 = 2.5 kW

- Calculate Motor Power (P_rated):

P_rated = 2.5 / (0.85 x 1.2) ~ 2.45 kW

- Selection: Choose the nearest larger standard power motor, which is 3.0 kW.

Safety Margin in Motor Selection

The safety margin (Ks) is necessary to ensure the motor is not overloaded under harsh conditions or short-term load fluctuations.

- Stable, continuous operation load (Pumps, Fans): Ks = 1.1

- Load with fluctuations (Conveyors, Machine tools): Ks = 1.15 – 1.25

- Heavy load, difficult starting (Crushers, Heavy mixers): Ks = 1.25 – 1.3

Comparing Electric Motor Types for the Most Effective Choice

AC vs. DC Motor Comparison

| Criterion | AC Motor (3-phase Asynchronous) | DC Motor (Brushed/Brushless) |

|---|---|---|

| Maintenance | Low (brushless, simple) | High (Brushed DC), Very Low (BLDC) |

| Starting Torque | Medium | Very High |

| Speed Control | Easy and precise (via VFD) | Very easy and linear (voltage control) |

| Efficiency | Good (IE3/IE4) | Good to Very Good (especially BLDC) |

| Application | Heavy industry, large power. | Precision equipment, robots, electric vehicles, small/medium power. |

Synchronous vs. Asynchronous Motor Comparison

| Criterion | Asynchronous Motor (Induction) | Synchronous Motor (PMSM) |

|---|---|---|

| Speed | Always less than synchronous speed. | Equal to synchronous speed (precise). |

| Rotor Construction | Wound or squirrel cage (simple, low cost). | Permanent magnets or field windings (more complex). |

| Efficiency | Standard to high (IE3) | Higher (IE4), especially at light loads. |

| Control | Uses VFD | Requires a more complex electronic controller (Servo Drive). |

Standard vs. Inverter Duty Motor Comparison

An Inverter Duty motor is a type of motor specially designed to operate stably and long-term when powered by a Variable Frequency Drive (VFD).

| Criterion | Standard Motor (Direct Operation) | Inverter Duty Motor (Used with VFD) |

|---|---|---|

| Speed | Fixed (according to supply frequency). | Infinitely variable adjustment (0 Hz to >60 Hz). |

| Insulation Protection | Standard. | Higher insulation class to withstand harmonics and voltage spikes from the VFD. |

| Cooling | Only effective at high speeds. | May include an independent cooling fan for stable operation at low speeds. |

| Application | Constant load, no speed adjustment needed. | Variable load, need to save electricity, need soft starting. |

Popular Electric Motor Brands and Which to Choose?

Choosing a reputable brand ensures quality, durability, and after-sales service.

- maxon motor (Switzerland):

- Specializes in precision drive solutions, particularly DC, BLDC, and Permanent Magnet PMSM motors of small and medium power.

- Trusted in demanding industries like medical, aerospace, robotics, and high-end automation due to superior precision, efficiency, and lifespan.

- ABB (Switzerland/Sweden):

- One of the world’s leading manufacturers of 3-phase AC motors and VFDs. Diverse, high-quality products, from standard to premium (IE4).

- Siemens (Germany):

- Known for their industrial motor lines, especially high-efficiency motors and optimal integration into automation systems (Totally Integrated Automation).

- Toshiba (Japan):

- Provides high-power AC motor lines, renowned for durability and reliability.

- Teco (Taiwan):

- Popular in Vietnam due to stable quality and competitive prices, mainly 3-phase AC motors.

Common Mistakes When Choosing Electric Motors & How to Avoid Them

Selecting Insufficient Power

- Consequence: Causes overload, continuous high operating temperature, leading to insulation failure and rapid winding burnout.

- How to Avoid: Always calculate the load power accurately and apply a minimum safety factor (Ks) of 1.1.

Failing to Evaluate Environmental Conditions

- Consequence: A motor without adequate IP protection will be infiltrated by water, dust, or chemicals, causing short circuits or corrosion.

- How to Avoid: Always check the environment (humidity, dust, chemicals, explosion hazard) and select the appropriate IP rating / insulation class / Ex certification.

Ignoring Starting Torque

- Consequence: For heavy loads (like air compressors, conveyors fully loaded with material), a motor with insufficient starting torque will fail to turn or overload the electrical system.

- How to Avoid: For heavy loads, consider using a DC Motor (with high starting torque) or an Inverter Duty Motor combined with a VFD to increase torque at low frequencies.

Choosing the Wrong Rotation Speed

- Consequence: If the speed does not match the machine’s requirement, you will have to use an excessively large gearbox or belt drive, increasing cost and reducing transmission efficiency.

- How to Avoid: Select a motor with a speed closest to the required speed. If a very low speed is needed, use a high-speed motor combined with a standard gearbox.

Incorrect Installation or Lack of Maintenance

- Consequence: Installing with the wrong mounting type (B3, B5) can cause vibration, shaft misalignment, leading to bearing failure and destruction of couplings/gearboxes.

- How to Avoid: Strictly adhere to installation standards (concentric alignment, belt tension), and perform periodic maintenance (bearing lubrication, vibration check).

FAQ – Frequently Asked Questions About Motor Selection

Should I choose a single-phase or three-phase motor?

Answer: Always prioritize a Three-phase Motor if a 3-phase power source is available. 3-phase motors have higher efficiency, smoother operation, longer lifespan, and are easier to control speed with a VFD compared to 1-phase motors. Single-phase motors should only be chosen for small power applications where a 3-phase source is unavailable.

Should I use a VFD with the motor?

Answer: Yes, if:

- You need to adjust the speed or the flow rate/head of the load.

- You want soft starting to reduce mechanical shock and decrease starting current.

- You want significant energy savings for pump and fan loads (because power is proportional to the cube of speed).

Does an IE3 motor save electricity?

Answer: Definitely yes. IE3 (Premium Efficiency) motors are proven to have significantly higher efficiency than IE1 or IE2. Although the initial investment cost is higher, an IE3 motor will quickly pay for itself (usually within 1-2 years) by reducing electricity consumption costs throughout its operating life.

What kW motor is suitable for a pump/fan/conveyor?

Answer: There is no fixed power. You must calculate based on the load requirements (Flow Rate/Head for pumps, Traction Force/Velocity for conveyors). After calculating the load power (P_load), apply the formula P_rated = P_load / (Efficiency x Ks) to select the nearest larger standard power rating.

Servo Dynamics Engineering: Official Maxon Distributor in Vietnam

As the official distributor of maxon motor in Vietnam, Servo Dynamics Engineering is committed to providing high-quality and precise drive solutions. We possess over 60 years of expertise in designing and distributing custom DC, BLDC, and PMSM motors, meeting the strict standards of industries requiring high precision such as medical, automation, and aerospace.

We offer:

- In-depth Consultation: Our team of experienced engineers is ready to help you calculate torque, power, and select the most suitable motor type (AC, DC, BLDC, PMSM) for your technical requirements and working environment.

- Custom Solutions: The ability to custom-manufacture motors according to specific technical specifications, ensuring the motor operates optimally in your application.

- Global Quality Products: Distributing advanced products from Maxon, renowned for outstanding reliability and performance.

Contact Servo Dynamics today for support in selecting the perfect electric motor solution for your project.

English

English